Device and method for calibrating position of stepped pad on rolling mill

A calibration device and step pad technology, applied in the direction of metal rolling stand, metal rolling mill stand, metal rolling, etc., can solve the problems of narrow space, inaccuracy, and laborious, etc., to reduce the time of changing rolls and solve the difficulty of verification Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is described in further detail now in conjunction with accompanying drawing.

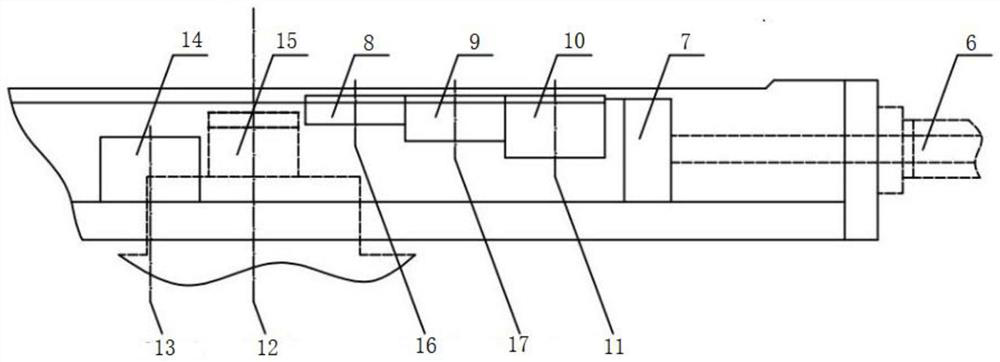

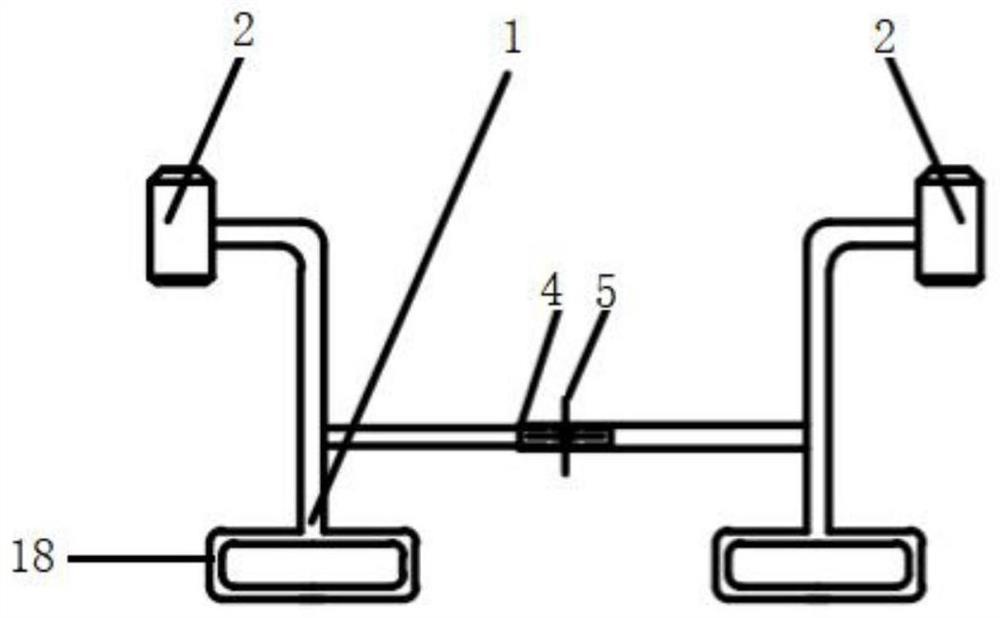

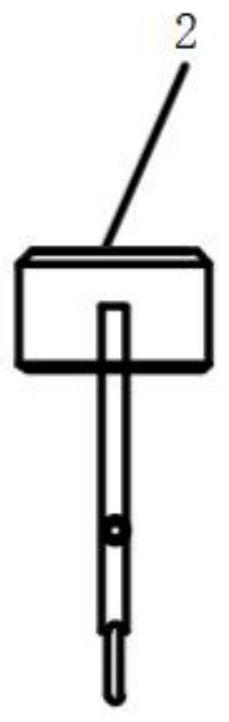

[0024] Such as Figure 2-4 , a step pad position calibration device on a rolling mill, including a calibration block 2, the number of calibration blocks 2 is 2, each calibration block 2 is provided with an "L" shaped handle 1, and between the "L" shaped handles 1 is provided The retractable anti-off connecting rod 4, insert the positioning pin 5 in the middle of the anti-off connecting rod 4, the distance between the calibration blocks 2 will not change, and prevent the calibration blocks 2 from falling off; when the calibration block 2 is not in use, pull out the positioning pin 5. The two calibration blocks can be stored separately. The single calibration block 2 is a cuboid structure, the roughness of the processed surface is Ra6.3, and the length is the dimension between the outer side of the moving frame 7 and the inner side of the "L"-shaped fixed frame 3 when the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com