Ball cutter machining method and ball cutter

A processing method and ball cutter technology, used in metal processing equipment, milling cutters, manufacturing tools, etc., can solve the problems of poor surface accuracy and smoothness of workpieces, low processing efficiency, and poor processing rigidity, and achieve a simple processing path and improve efficiency. , Enhance the effect of surface finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

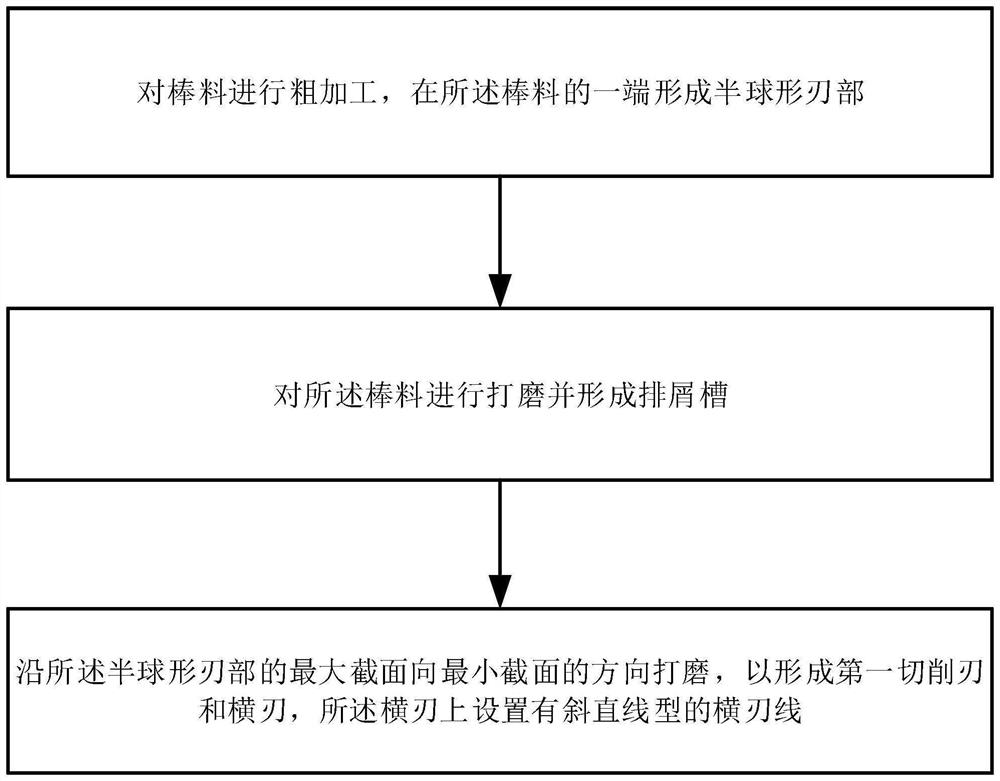

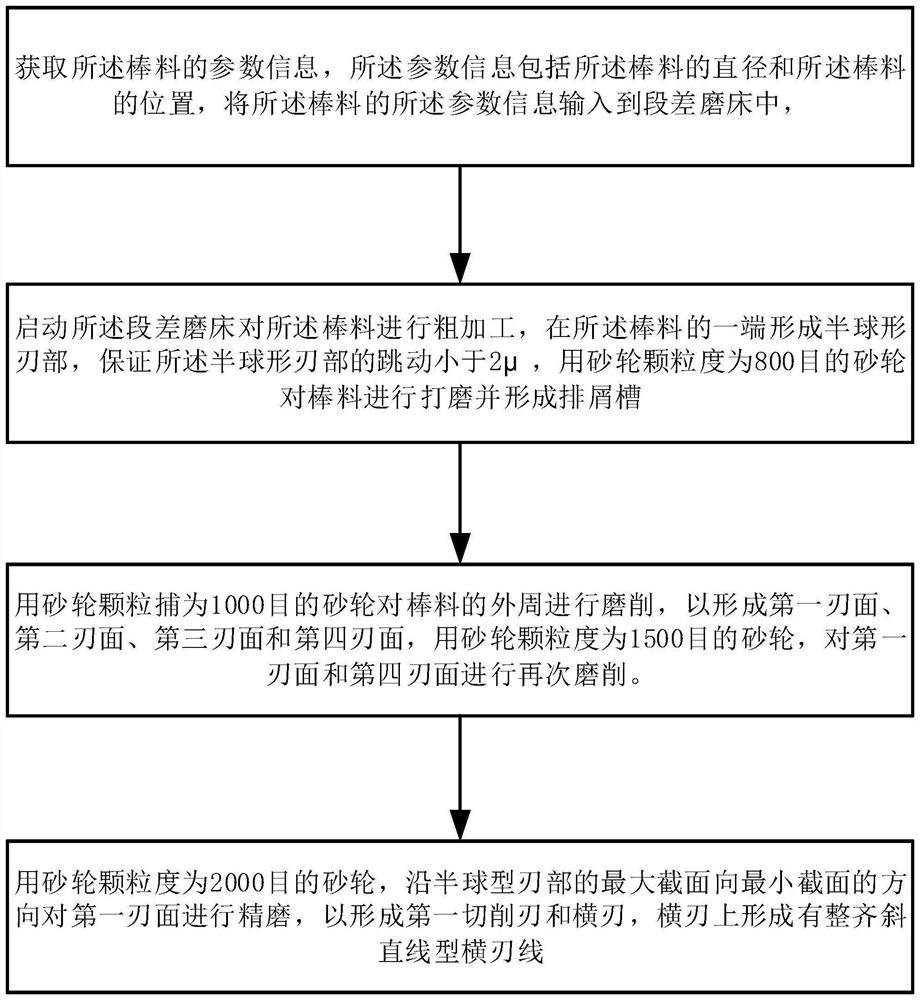

Method used

Image

Examples

Embodiment 2

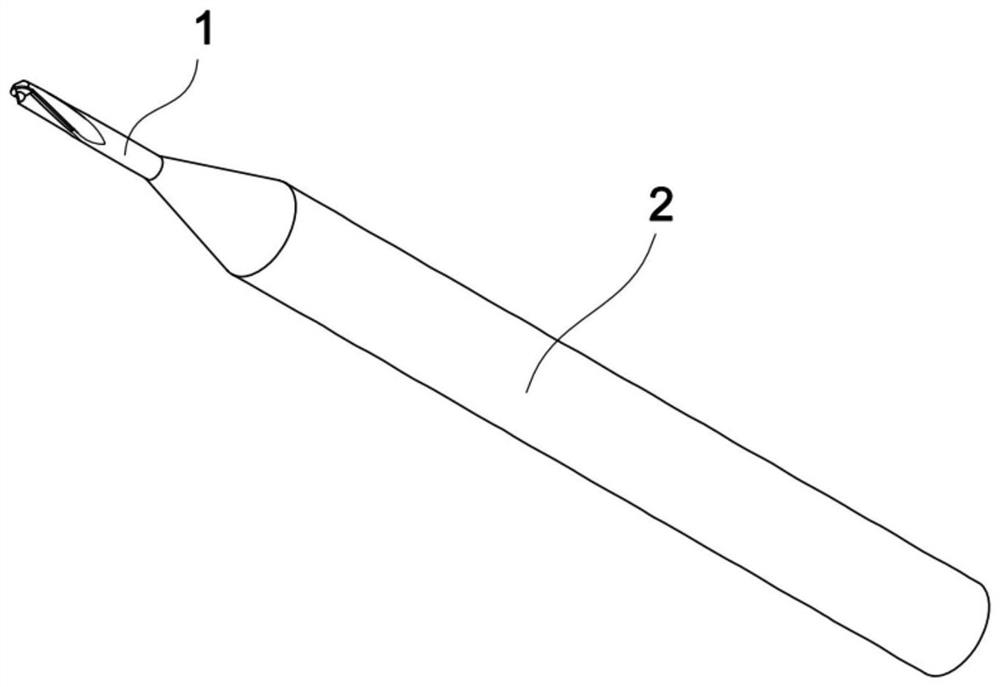

[0051] This embodiment provides a kind of ball cutter, adopts the processing method of above-mentioned ball cutter, such as Figure 3-Figure 4 As shown, the ball cutter includes a handle 2 and a cutting part 1. The cutting part 1 is arranged at one end of the handle 2. The cutting part 1 includes a body 11 and a first cutting edge 1111. The body 11 is provided with a helically extending flute. 116, the two first cutting edges 1111 are arc-shaped and symmetrically arranged on the end of the body 11 away from the handle 2, the two first cutting edges 1111 intersect to form a chisel edge 112, and the chisel edge 112 is provided with an oblique linear chisel edge Line 1121.

[0052] Such as Figure 5 As shown, the ball cutter provided in this embodiment has a neat oblique linear chisel edge line 1121 on the chisel edge 112 between the two arc-shaped and symmetrical first cutting edges 1111, which enhances the surface finish of the workpiece to be processed. effect, thereby impro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com