Plug-in type junction box

A junction box and plug-in technology, which is applied in the field of junction boxes, can solve problems such as resource waste, junction box damage, junction box protrusion, etc., and achieve the effects of reducing installation difficulty, improving work efficiency, and improving aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0031] Example

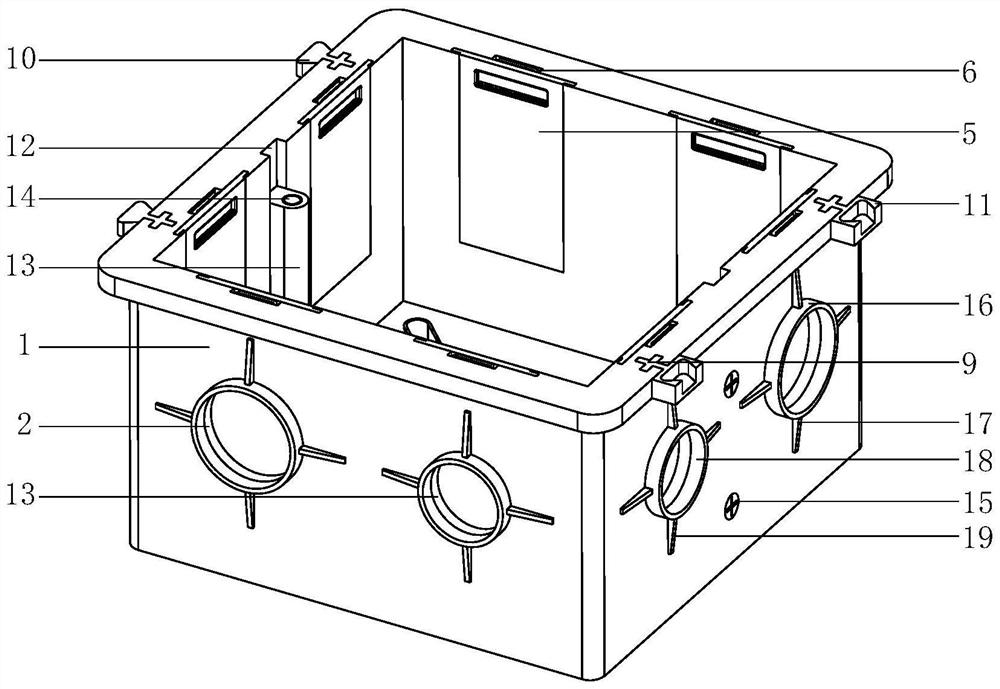

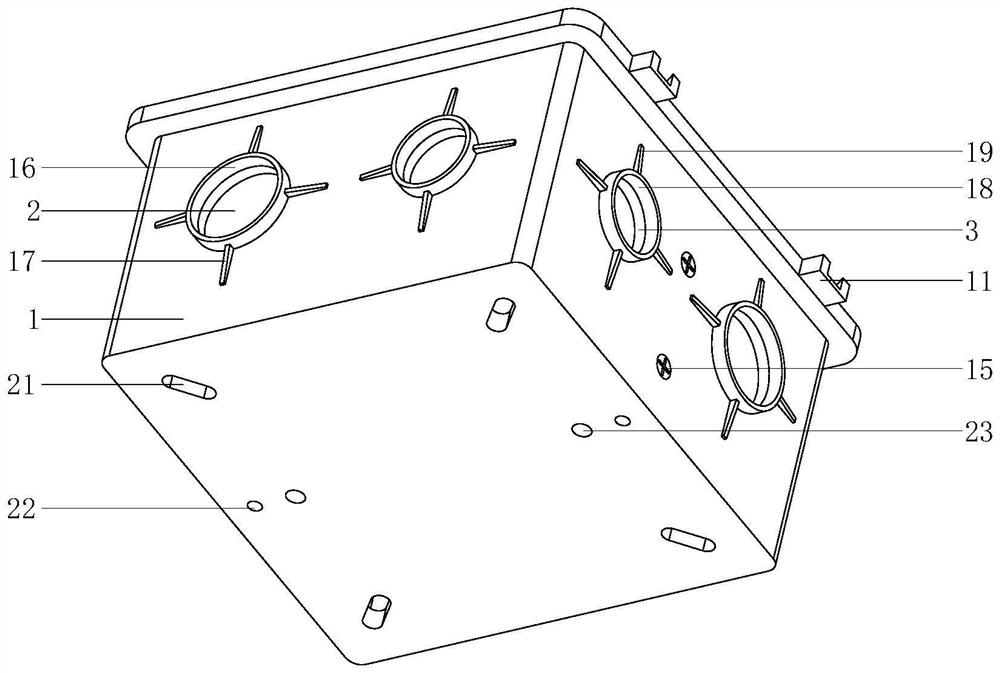

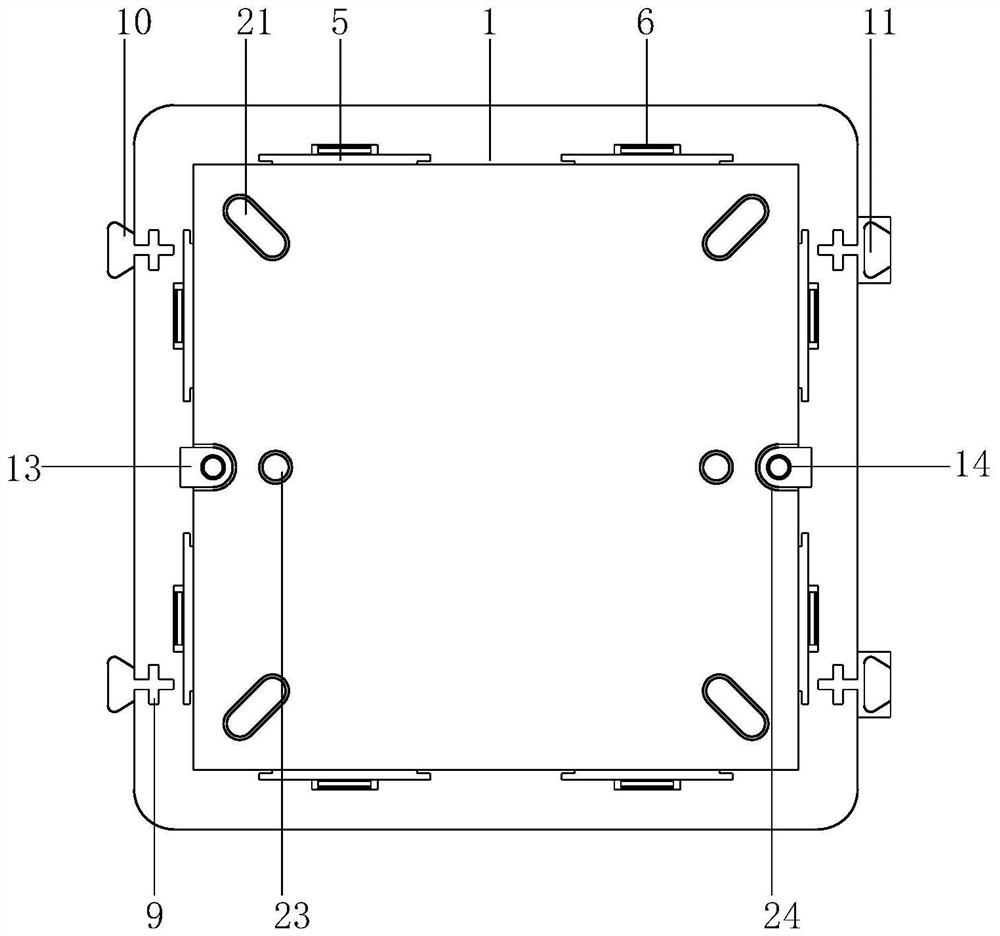

[0032] Such as figure 1 , image 3 , Figure 4 , Image 6 and Figure 8 As shown, a plug-in junction box proposed in one embodiment of the present invention, including the box 1, and the four sides of the casing 1 have a first wiring port 2, and one side of the first terminal port 2. There is a second wiring port 3, and there are two inner walls of the cartridge 1 in the inner wall. There are two mounting grooves 4 corresponding to the first wiring port 2 and the second wiring port 3, and there is a block 5 in the mounting groove 4. The outer side wall of the stopper 5 is fixedly connected to the elastic cartridge 6, and the recess 7 that matches the elastic card block 6 is provided on the casing 1, and two sets of card slots 8 are provided on the casing 1. The card groove 8 is inserted with a cardifier 9, and the outer end of the set of card member 9 is fixedly connected to the connecting block 10, and the outer end of the other set of card member 9 is fixedly connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com