Manufacturing method of 3D digital inner container

A production method and 3D technology, applied to footwear, other household appliances, household appliances, etc., can solve problems such as inconsistency, squeezed feet, and inner liner size deviation, and achieve the effect of size standard and comfortable wearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

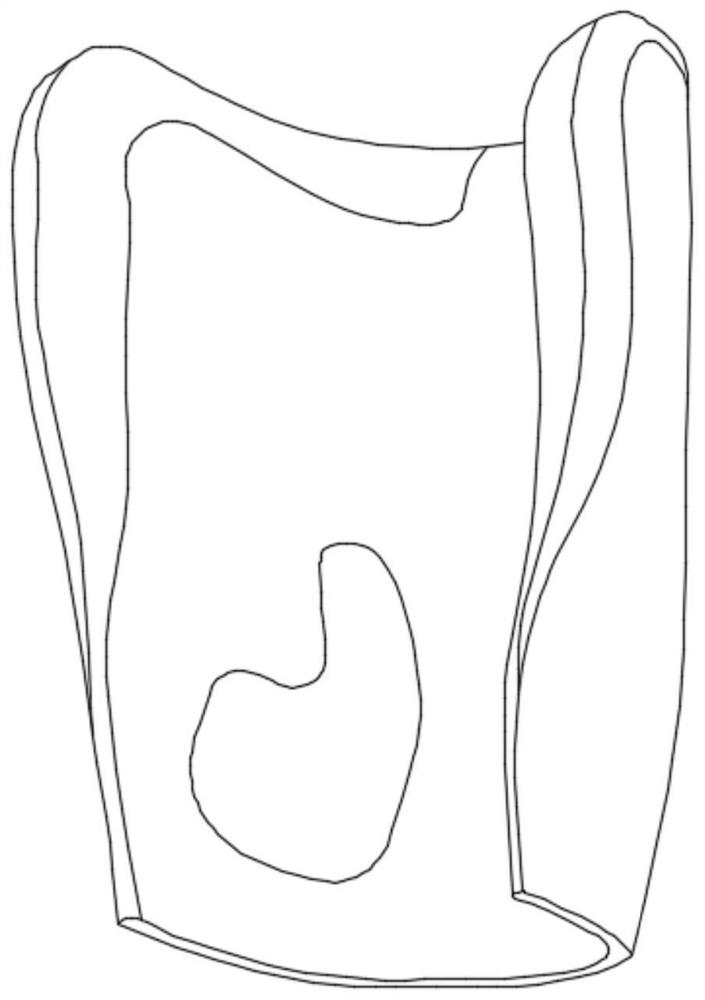

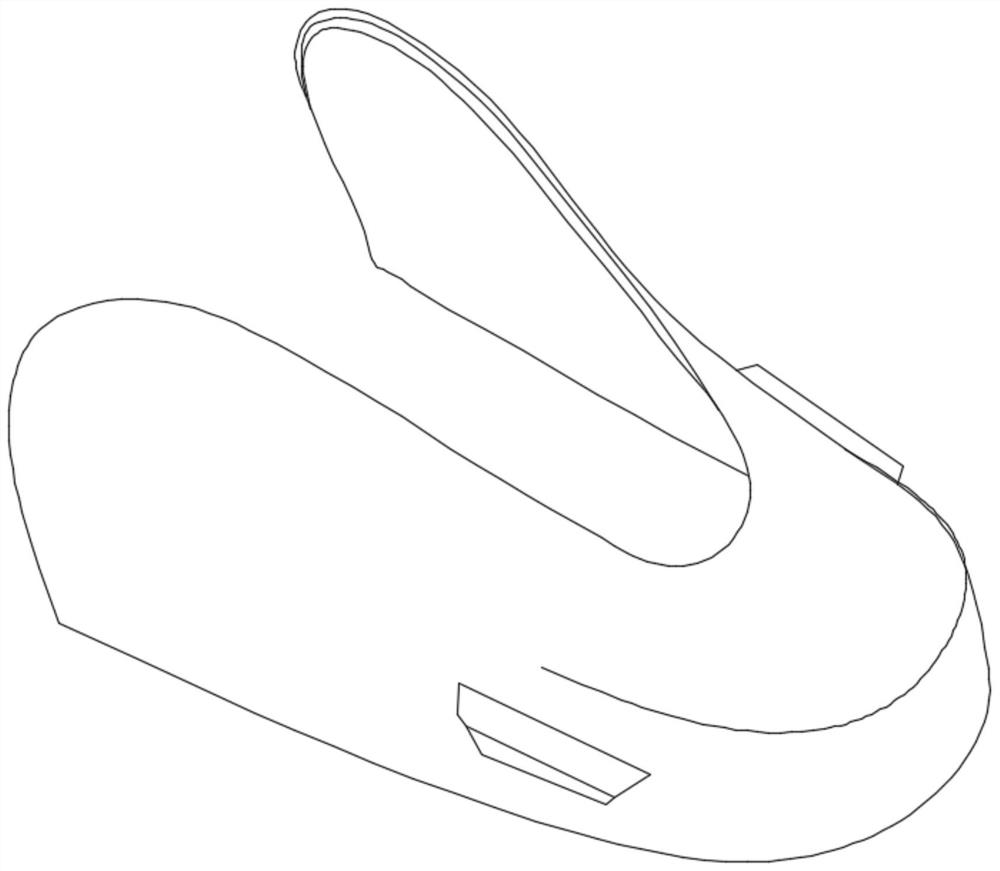

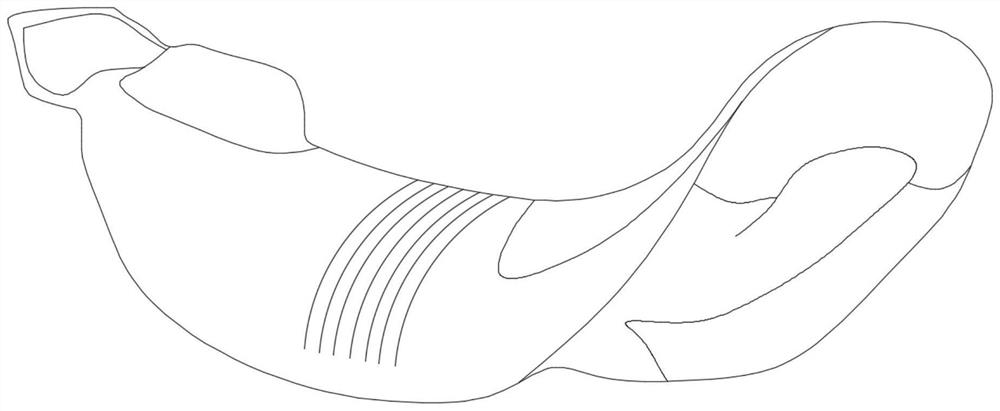

[0022] See Figure 1 to 3 The present invention provides a technical solution: a method of fabricating 3D digital liner, including the following steps:

[0023] S1: A full-scale scan of the human body by means of a hand-held 3D scanner to obtain a 3D simulation data of the human body;

[0024] S2: According to the 3D simulation data of the human body, the size data of the inner cavity of the relative rotation shoe housing is integrated into the back tie, front and tongue 3D model files inside the wheel skating shoes;

[0025] S3: Making mold corresponding to the fabrication of the back tie, the front tuning of S2, the front and the tongue 3D model document;

[0026] S4: Heating the thermoplastic material and a plurality of fabrics and placed in the mold in S3, by cooling to obtain the post-tie, front and shoes tongue;

[0027] S5: Or bind the SBR through the Leva binding, the front and the tongue to give the overall structure of the hollower liner.

[0028] Those skilled in the art...

Embodiment 2

[0037] A 3D digital liner manufacturing method, including the following steps:

[0038] S1: A full-scale scan of the human body by means of a hand-held 3D scanner to obtain a 3D simulation data of the human body;

[0039] S2: According to the 3D simulation data of the human body, the size data of the inner cavity of the relative rotation shoe housing is integrated into the back tie, front and tongue 3D model files inside the wheel skating shoes;

[0040] S3: Prints by the 3D printer to print the back tie, the front and the tongue 3D model file in S2 by the 3D printer, to obtain the post-tie, front and shoes tongue within the precision shape;

[0041] S4: Or through the Laika binding SBR to the back tie, the front and the tongue to give the whole structure of the wheel skating shoes in the overall structure.

[0042] Those skilled in the art will appreciate that a 3D digital liner manufacturing method is provided, first scanned by a handheld 3D scanner, and stored data into a three...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com