Method for testing injection coefficient of steam injector for industrial steam extraction

A technology for industrial steam extraction and testing methods, which is applied in the testing of mechanical components, testing of machine/structural components, jet pumps, etc. It can solve problems such as large differences, and achieve the effect of easy implementation, scientific algorithm, and reasonable and reliable results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

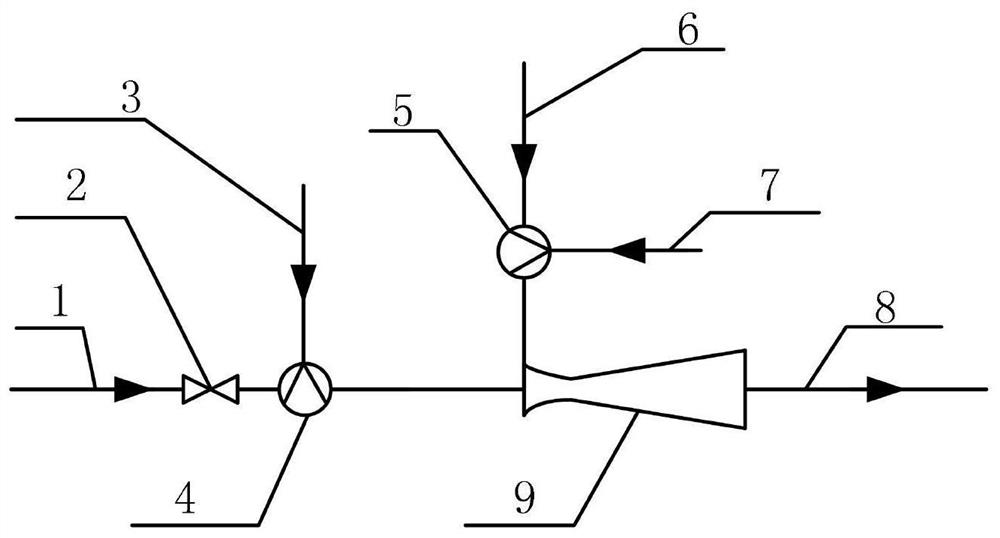

[0020] The invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

[0021] A steam ejector injection coefficient test method for industrial string, and its key technique is:

[0022] a. First, confirm that the flow meter is no drift, and then the accuracy of the cooling flow of the water flow in accordance with the power steam temperature flow of the water flow device is calculated according to the power steam.

[0023] b. When the heat transfer flow is constant, the inhaled steam line is turned off to cut off the steam inhale steam flow and the inhaled steam temperature flow, and the precision transmitter is installed on the reduced temperature of the power steam line, by power steam The value of the enthalpy values before and after the temperature is measured, and the accuracy of the power steam is reduced, and the effects of the installation process are excluded.

[0024] c. For an adjustable steam ejector, if...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com