Connector with voltage protection function and mainboard

A technology for voltage protection and connectors, which is applied in the field of connectors and motherboards with voltage protection functions. It can solve the problems of broken damaged parts, prone to bending, and inability to protect against dust, so as to improve the buffering strength, avoid loosening, Avoid the effect of bending and breaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

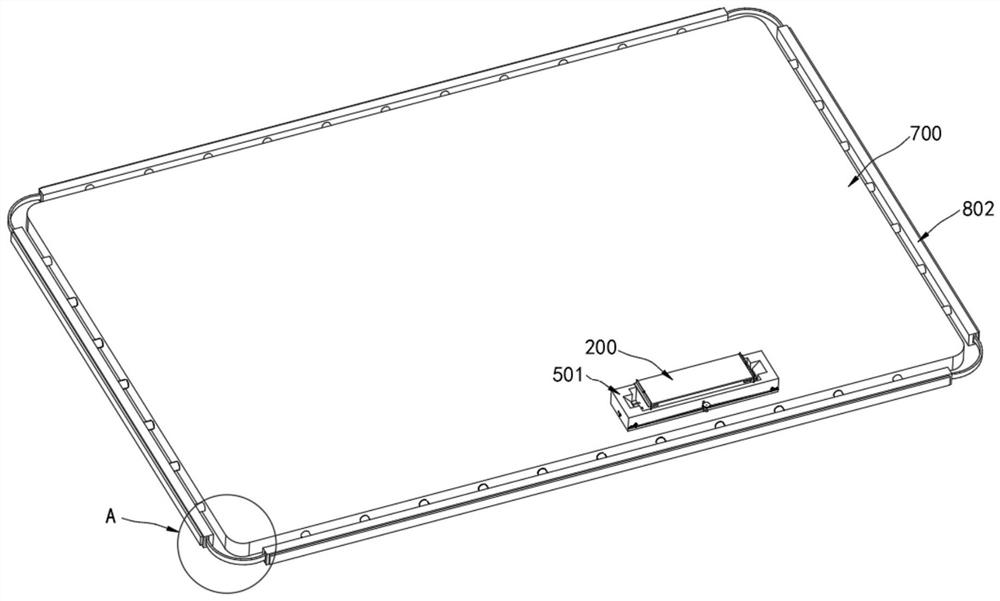

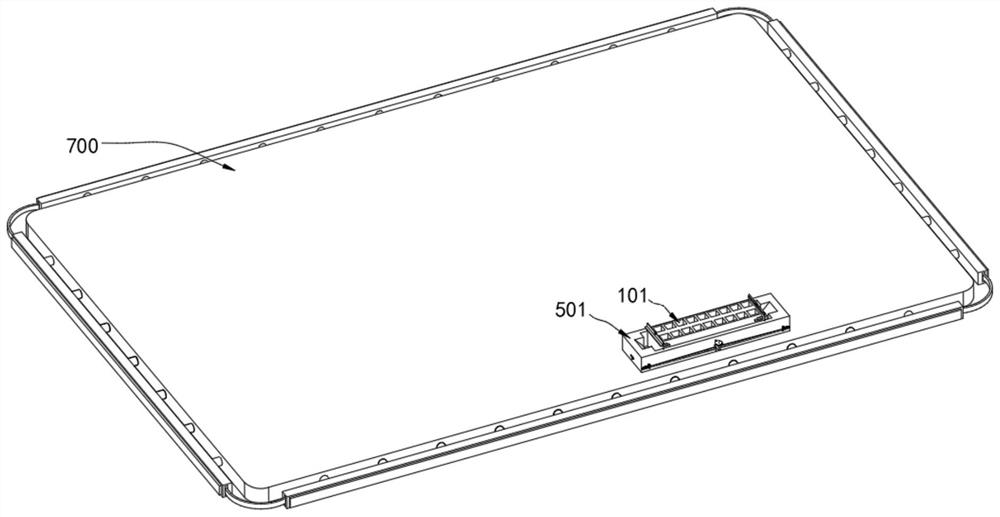

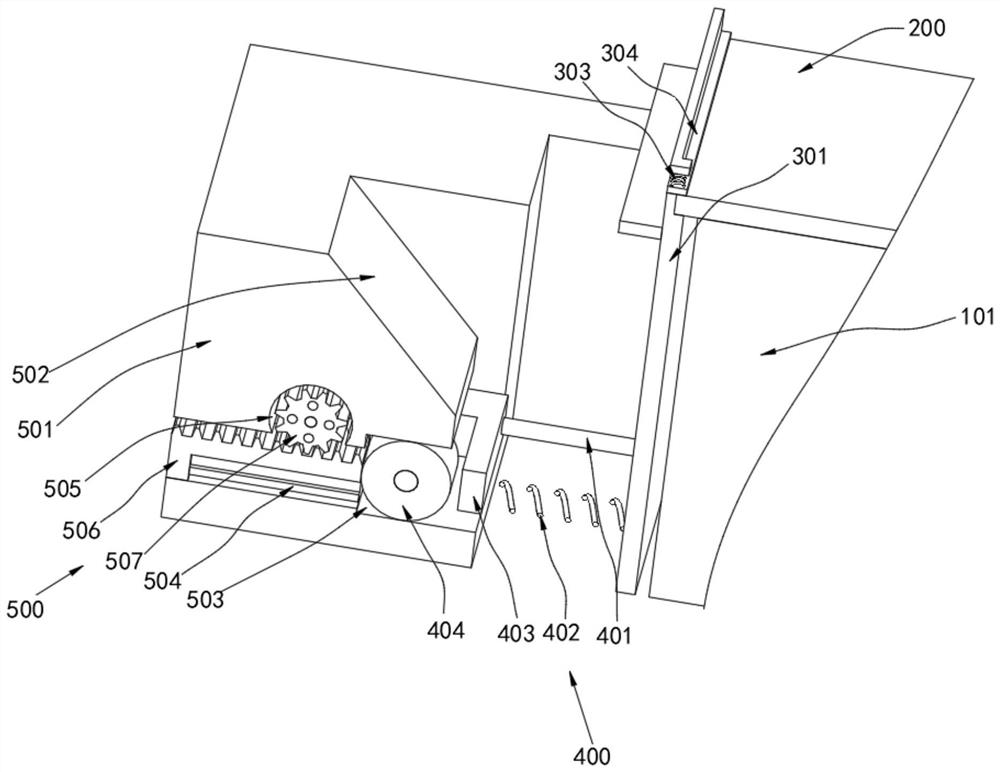

[0025] refer to Figure 1 to Figure 4 , a connector with a voltage protection function, including a connector assembly 100, including a connector body 101, the connector body 101 has the same structure as the connector 2 in the authorized announcement number CN102147644B, and the two ends of the front and rear sides of the connector body 101 Both are provided with protruding rods 102; the dustproof plate 200, the dustproof plate 200 is covered on the top of the connector body 101, which can be protected from dust before connecting the power supply device; the pressing component 300, the pressing component 300 and The dustproof plate 200 is movably connected; the fixing component 400 is connected to the pressing component 300; the installing component 500; and the pulling component 600.

[0026] refer to Figure 1 to Figure 4 , the pressing down assembly 300 includes two sets of side plates 301 with the same structure, the opposite sides of the two sets of side plates 301 are ...

Embodiment 2

[0032] refer to figure 1 , figure 2 and Figure 5 The adjacent airbags 803 are connected with arc-shaped buffer sheets 805. When the airbags 803 on one side are squeezed, the adjacent airbags 803 can be squeezed by the outer buffer sheets 805 to improve the buffering force.

[0033] All the other structures are the same as in Example 1.

[0034] Working principle: Before connecting the power supply device, the connector body 101 presses down on the side plate 301, so that the roller body 404 can roll on the inclined surface 502, and as the side plate 301 moves down, the roller seat 403 on the roller body 404 is on the Slide on the guide rod 401, and squeeze the extension spring 402 at the same time. When the roller body 404 is aligned with the limit groove 503, the roller body 404 is no longer under the pressure of the inclined surface 502, and the roller seat 403 is driven under the action of the extension spring 402. The guide rod 401 slides in the opposite direction, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com