Polytetrafluoroethylene lip oil seal formed through compression molding at one time

A compression molding and oil sealing technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of difficult product quality, easy to break, stiff PTFE sheet, etc. The effect of preventing bending breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

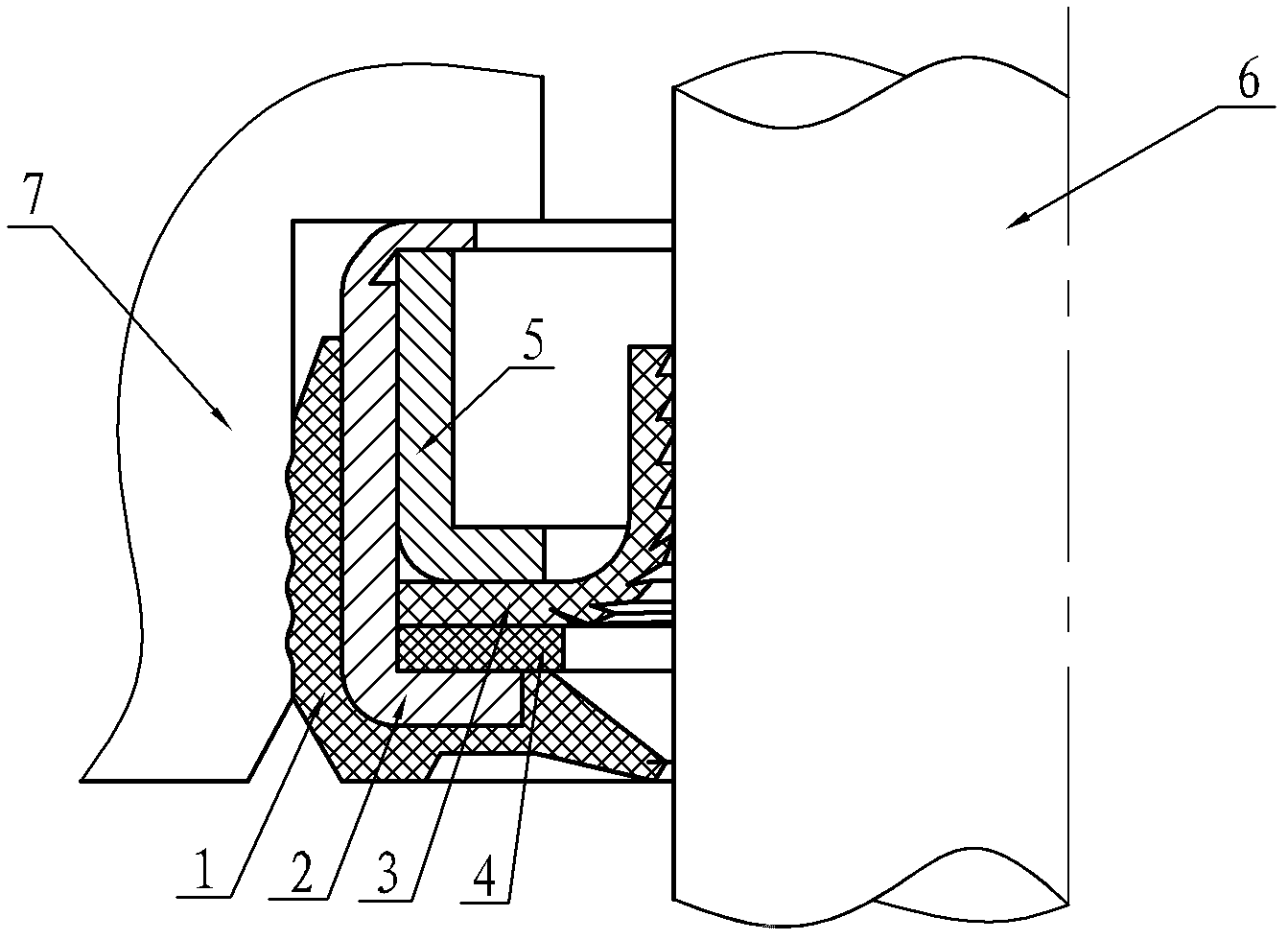

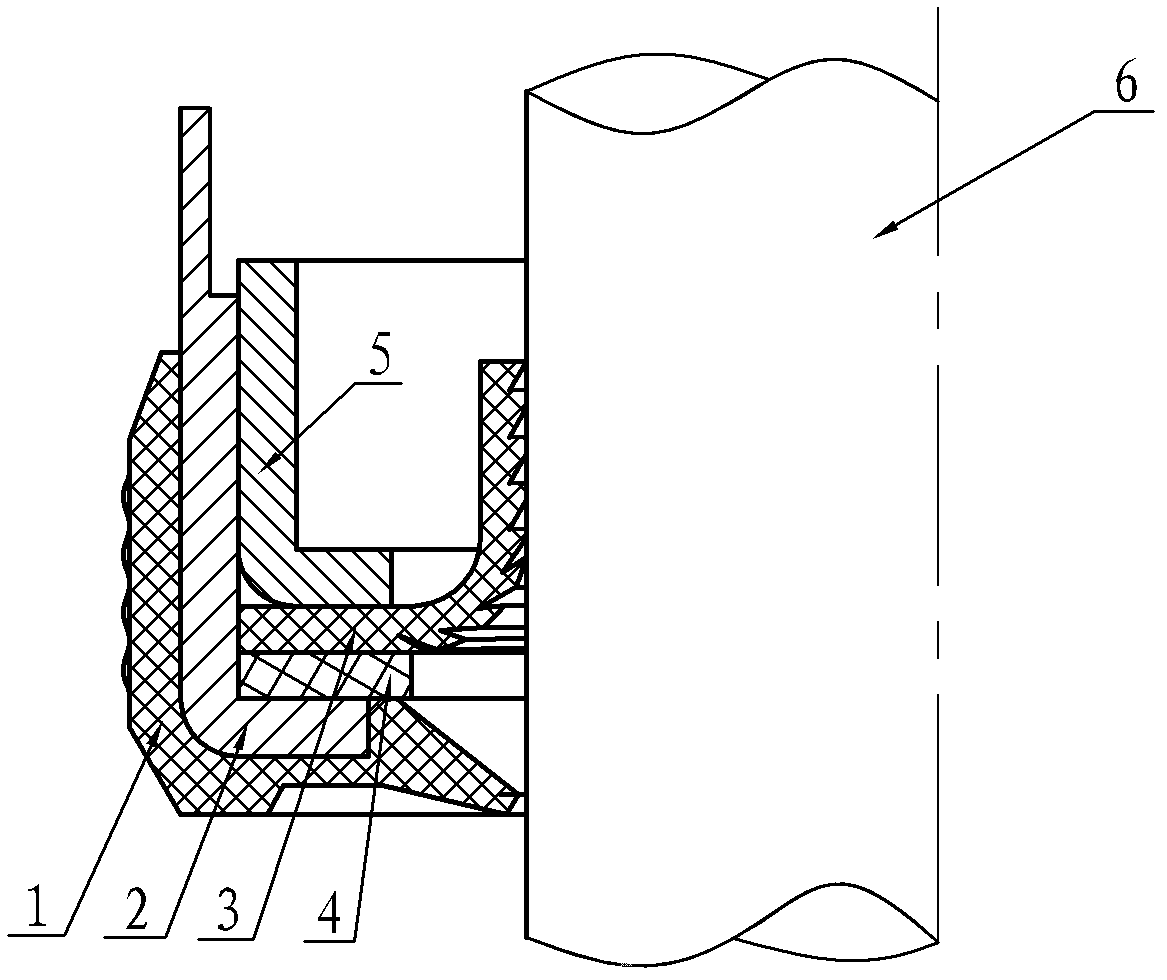

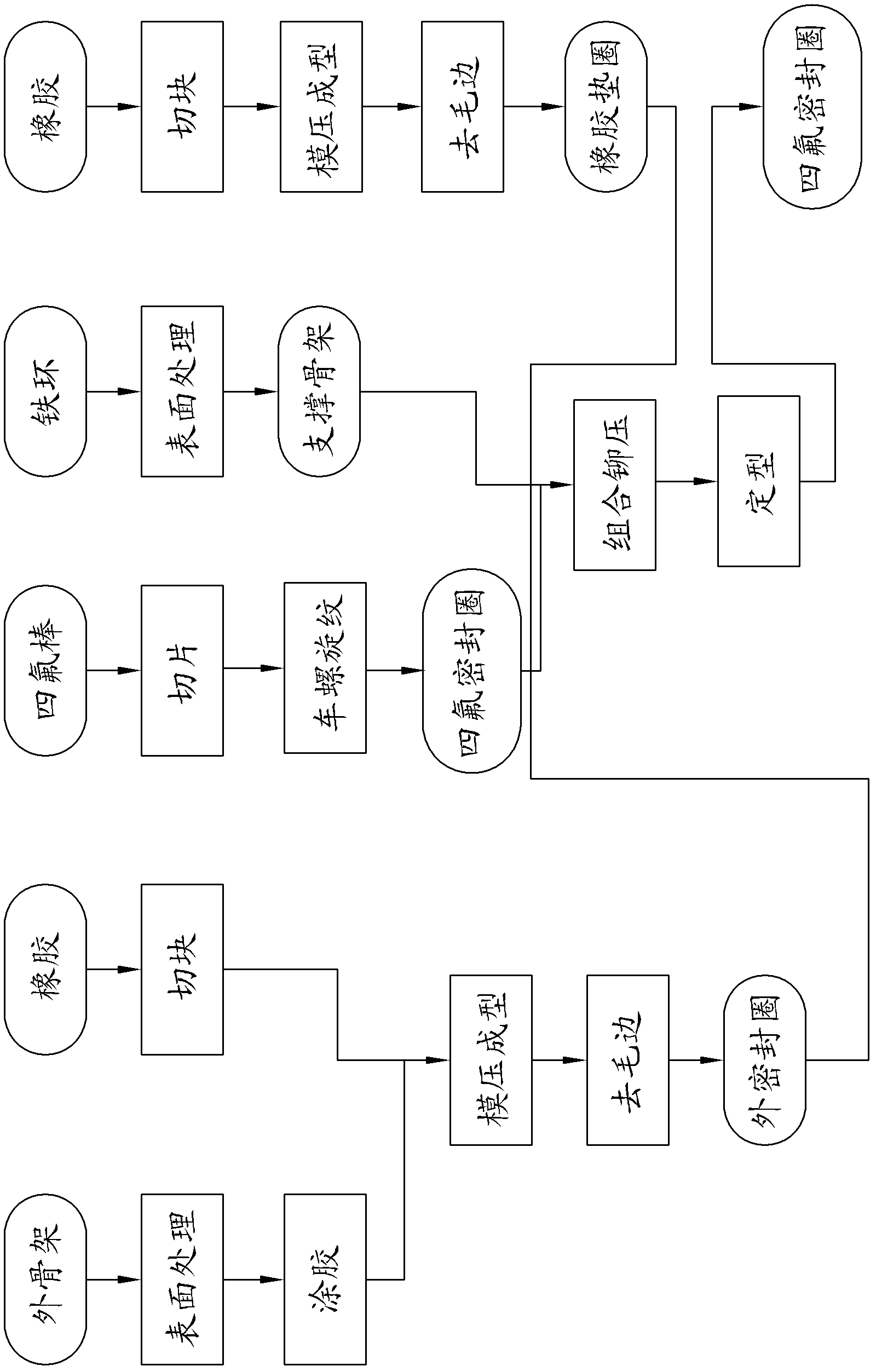

[0026] Embodiment 1: One-time molding of PTFE lip oil seal, such as Figure 4 , Figure 5 As shown, it consists of a static seal 1, a metal outer frame 2 and a PTFE inner sealing ring 3. The static seal 1 includes an outer circular seal 11 and an inner ring sealing lip 12. The metal outer frame 2 is embedded in the static In the sealing 1, the PTFE inner sealing ring 3 is composed of an adhesive ring 31 and a spiral sealing ring 32, the adhesive ring 31 is molded and bonded with the inner surface of the static seal 1 and the metal outer frame 2, and the spiral sealing ring 32 is provided with an inner helical sealing lip 33 on the inner side of the contact section with the rotating shaft, and an outer helical sealing lip 34 is provided on the outer surface of the helical sealing ring 32, and the inner helical sealing lip 33 and the outer helical sealing lip 34 have a pitch The same, concentric in the radial direction and staggered by a pitch distribution.

[0027] The produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com