Crimping tool for spliced combined iron core

A technology of combining iron core and tooling, applied in the field of iron core crimping, can solve the problems of iron core damage, crimping tooling is easily damaged, and the crimping tooling cannot locate the iron core, etc., so as to improve the tightness and the pressing efficiency. , to ensure the effect of roundness and coaxiality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

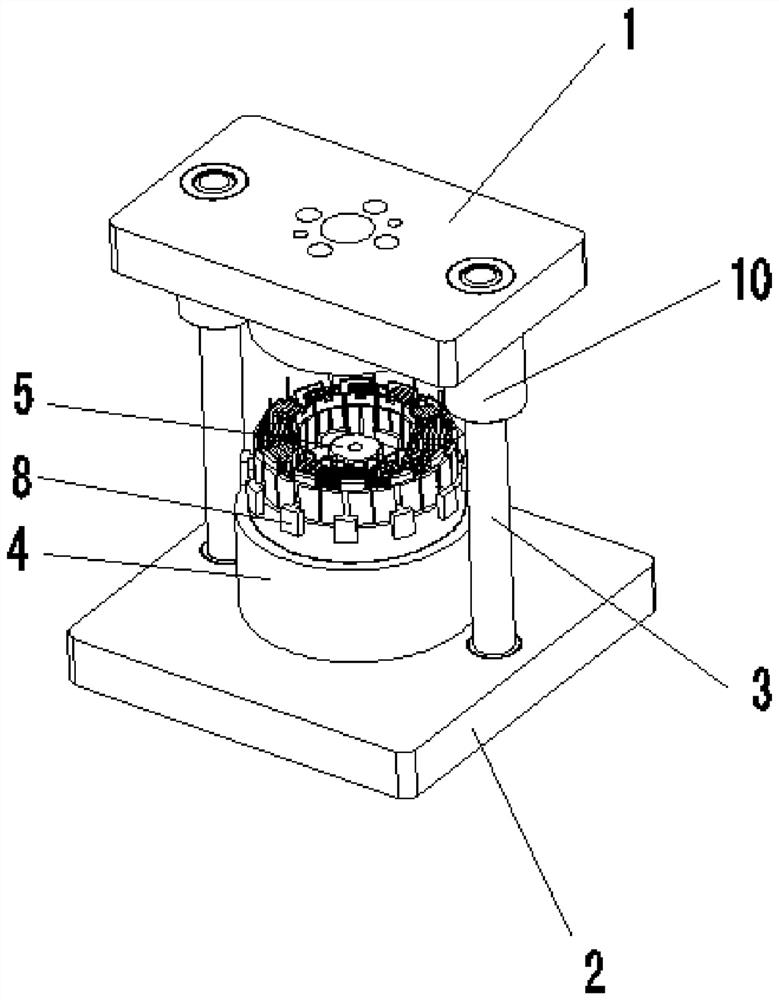

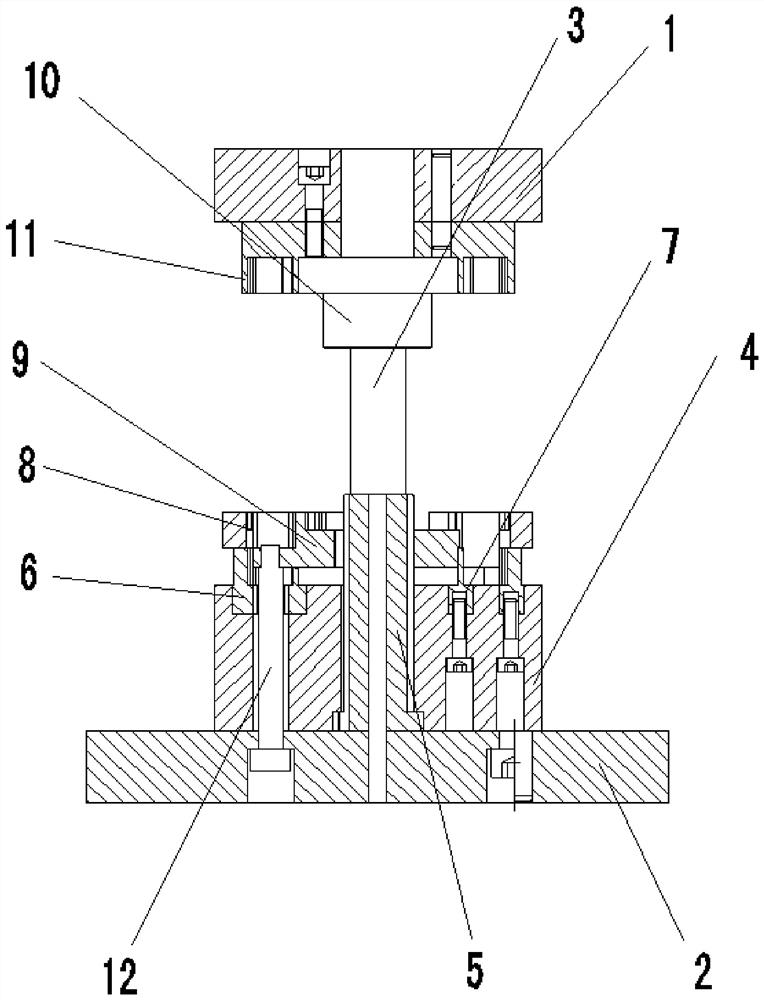

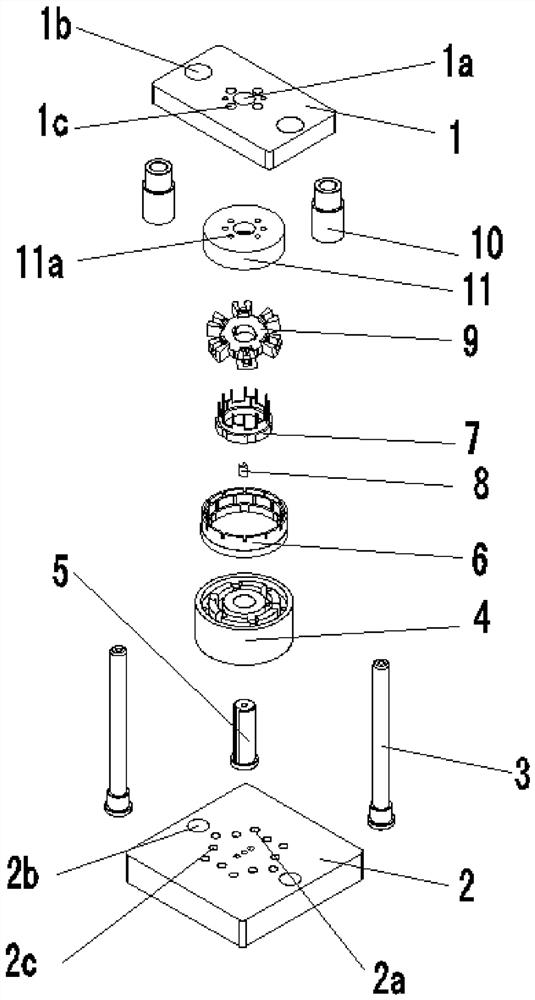

[0023] see Figure 1 to Figure 7 , a crimping tool for splicing combined iron cores, including an upper mounting base 1 and a lower mounting base 2, a plurality of positioning holes 2a are arranged on the lower mounting base 2, and the left and right sides of the upper end surface of the lower mounting base 2 Two guide holes 2b are arranged axisymmetrically, and a guide column 3 is arranged in the guide hole 2b, and a vertical structure is formed between the guide column 3 and the lower mounting seat 2, and a fixed seat 4 is arranged at the center of the upper end of the lower mounting seat 2 , the center of the fixed base 4 is provided with a guide shaft hole 4a, a guide mandrel 5 is arranged in the guide shaft hole 4a, and the height of the guide mandrel 5 is greater than the height of the guide shaft hole 4a. The guide shaft hole 4a of the fixed base 4 is a stepped hole, the upper end of the guide shaft hole 4a is a small-diameter hole, and the lower end is a large-diameter...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap