Method for reducing cerium content in praseodymium neodymium chloride and preparation method of praseodymium neodymium oxide

A technology of praseodymium and neodymium chloride, which is applied in the preparation/processing of rare earth metal compounds, rare earth metal oxides/hydroxides, etc., can solve problems such as affecting product quality and difficult-to-wash section separation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] In the present invention, the preparation method of said neodymium praseodymium neodymium chloride organic phase solution preferably comprises the following steps:

[0026] The raw material liquid of praseodymium neodymium chloride and the organic phase extraction agent are subjected to multistage countercurrent extraction to obtain the organic phase solution of neodymium praseodymium neodymium chloride.

[0027] The present invention has no special requirements on the source of the praseodymium and neodymium chloride raw material solution.

[0028] The present invention has no special requirements on the type and source of the organic phase extractant.

[0029] In a specific embodiment of the present invention, the number of stages of the multi-stage countercurrent extraction is preferably 57 stages. During the multistage countercurrent extraction, during each stage of countercurrent extraction, the flow rate ratio of the rare earth chloride feed liquid containing pra...

Embodiment 1

[0054] A multi-stage countercurrent continuous extraction machine with three outlets is adopted, including 57 stages of countercurrent extraction. The organic extract phase is fed from the first stage, and the rare earth chloride material liquid containing praseodymium and neodymium is fed from the 57th stage. Praseodymium and neodymium chloride The aqueous solution (aqueous phase washing solution) and ascorbic acid are fed from the 84th stage, and the 85th stage obtains the purified praseodymium neodymium chloride organic phase solution.

[0055] Wherein, the flow velocity of the rare earth chloride material liquid containing praseodymium element and neodymium element is 18L / min, the flow velocity of organic phase extractant is 1.5L / min, and the flow velocity of praseodymium neodymium chloride aqueous solution (aqueous phase washing liquid) is 1.5L / min. min, during the 84th grade of washing, 5% ascorbic acid aqueous solution is added dropwise to the mixed solution of the prase...

Embodiment 2~14

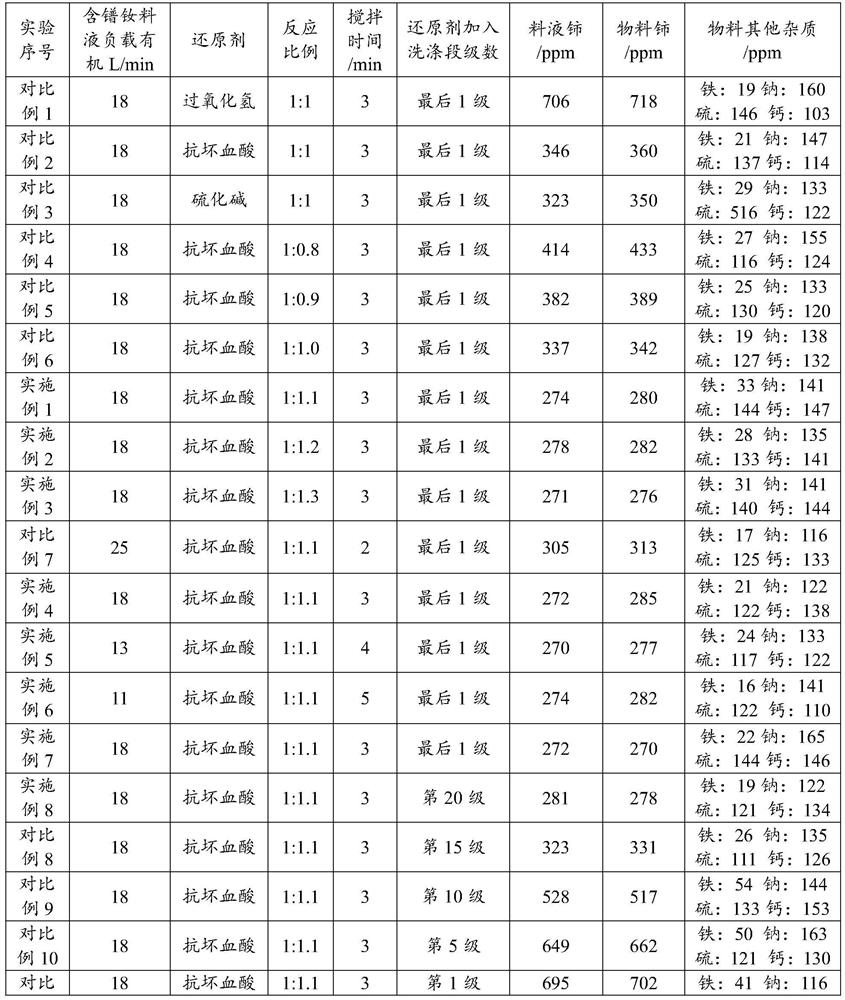

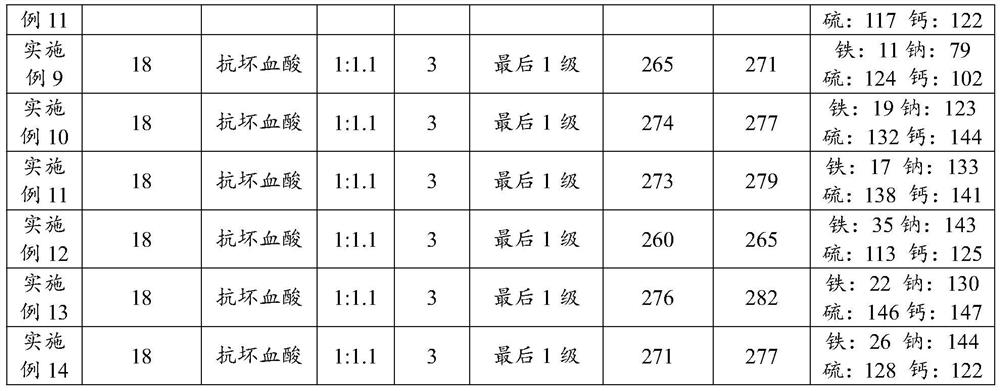

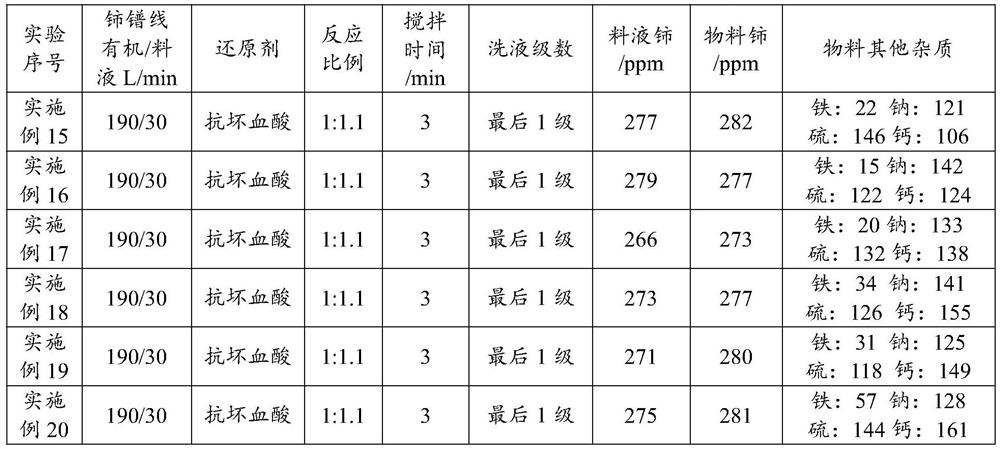

[0059] The methods of Examples 2-14 are basically the same as those of Example 1, and the specific implementation parameters and results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com