Product production process quality control method, device and equipment and storage medium

A quality control method and production process technology, applied to equipment and storage media, product production process quality control methods, and device fields, can solve problems such as poor recognition of abnormal patterns in control charts, improve generalization capabilities, and solve poor recognition effects , the effect of improving the recognition accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

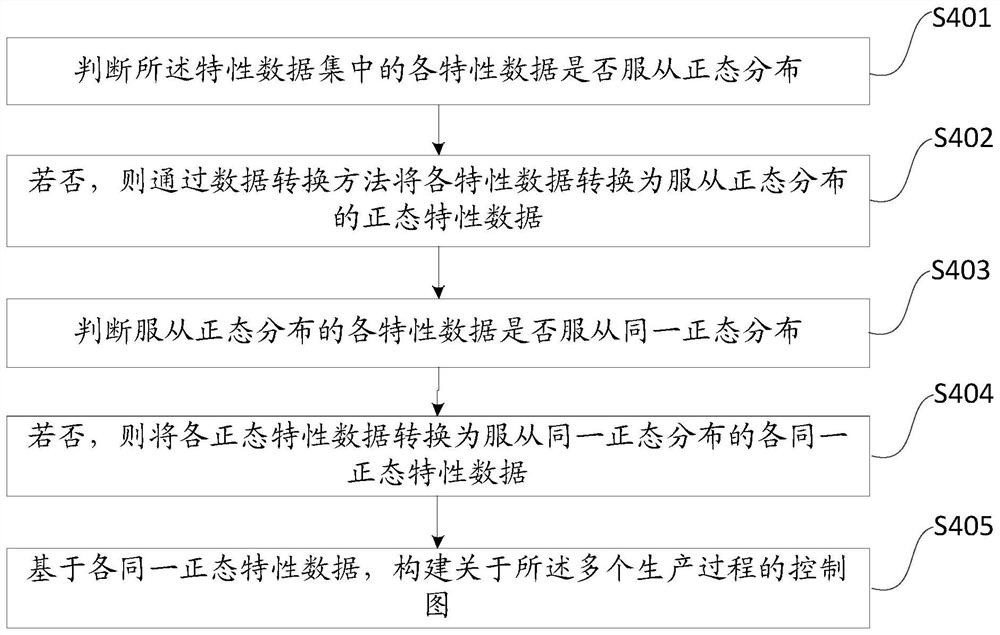

[0064] see image 3 , as an implementation manner, S40 specifically includes:

[0065] S401. Determine whether each characteristic data in the characteristic data set obeys a normal distribution;

[0066] In the specific implementation process, each characteristic data in the characteristic data set belongs to the production process of different types of products, and does not necessarily obey the normal distribution. In order to generate the production process of different types of products into the same control chart, it is necessary to generate Before making the control chart, ensure that the characteristic data obey the normal distribution. Therefore, it is first necessary to judge whether each characteristic data in the characteristic data set obeys a normal distribution.

[0067] Specifically, the probability paper can be used to obtain the normality correlation coefficient of each characteristic data to judge whether the data obey the normal distribution. If not, exe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com