Adjustable clamp based on aviation part machining

A component and shape adjustment technology, which is applied in the field of aviation parts processing, can solve the problems of poor clamping effect of aviation special-shaped plates, reduced machining accuracy, offset or falling off of aviation plates, etc., so as to facilitate high-strength processing and improve effective Clamping area, the effect of increasing the clamping area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

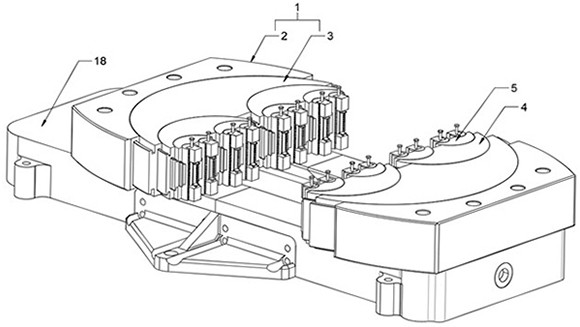

[0028] Embodiment one, as figure 1 and figure 2 As shown, an adjustable fixture based on aviation parts processing includes two sets of clamping mechanisms 1 symmetrically arranged, and the two sets of clamping mechanisms 1 can move relative to each other to form a clamping space; the clamping mechanism 1 includes The base 2 and the first clamping block 3, the first clamping block 3 is slidably arranged on the base 2, and a plurality of second clamping blocks 4 are slidably arranged on the first clamping block 3 along its own radial direction, the first clamping block 3 The sliding paths of the second clamping block 4 and the second clamping block 4 are both arc-shaped, and the two sets of clamping mechanisms 1 are used to adapt to clamping parts of different shapes through the arc deflection of the first clamping block 3 and the second clamping block 4; the clamping mechanism 1 It is a multi-level fixture, including several levels of clamping blocks, that is, the first clam...

Embodiment 2

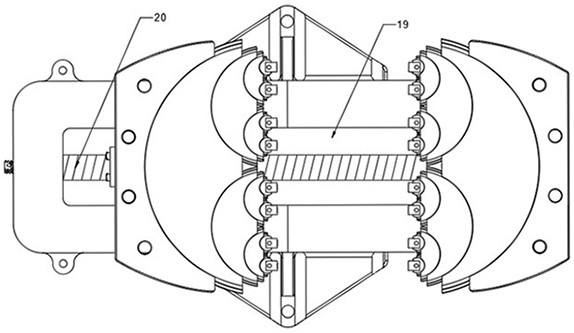

[0030]Embodiment 2. Embodiment 1 provides a clamp that can adapt to the clamping of special-shaped plates. Although the clamping area is improved by adapting to the shape of the part, the clamping strength of the special-shaped part is improved compared with the ordinary clamp, but only through the symmetrical The set clamping part 6 restricts the movement of the part, which is equivalent to restricting the left and right movement of the part. The limit direction of the part is relatively small. After the aviation parts are clamped, two processes of processing and testing are required. The processing includes grinding, cutting, drilling Holes, etc., its strength is relatively large, and the detection of cracks, roughness, etc. is detected by optical instruments, and its strength is relatively small. The clamping strength of the fixture in Example 1 meets the strength required for detection, but it is difficult to meet the strength of processing with high strength. process, in t...

Embodiment 3

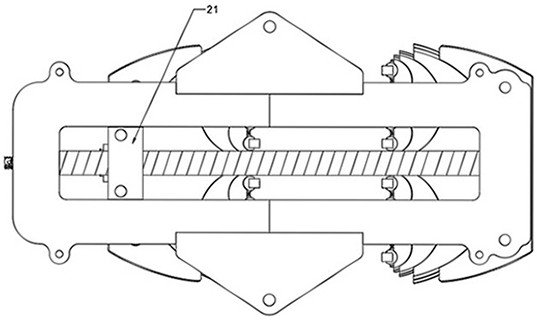

[0031] Embodiment three, as Figure 6 to Figure 8 As shown, the shapes of the first clamping block 3, the second clamping block 4 and the third clamping block 5 are all semicircular, and the shapes of the first clamping block 3, the second clamping block 4, the third clamping block 5 and the arc-shaped main body 7 The arc-shaped ends are all provided with arc-shaped slide rails 13, and the base 2, the first clamp block 3, the second clamp block 4 and the third clamp block 5 are all provided with arc-shaped slide grooves 14, and the arc-shaped slide rails 13 and arc-shaped The cross-sectional shape of the chute 14 is "T" shape, and the arc-shaped slide rail 13 on the first clamping block 3 is adapted to the arc-shaped chute 14 on the base 2, so that the first clamping block 3 moves along its own The trajectory of the arc-shaped slide rail 13 is arc-shaped deflection, and the arc-shaped slide rail 13 on the second clamping block 4 is adapted to the arc-shaped slide groove 14 on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com