Fixing device for sofa cushion and bed sheet

A sofa cushion and fixer technology, which is applied in the field of fixers, can solve problems such as troublesome finishing process, sofa seat deformation, and little effect, and achieve the effects of improving clamping stability, reducing space occupation, and increasing clamping area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

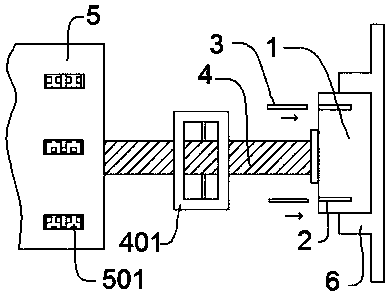

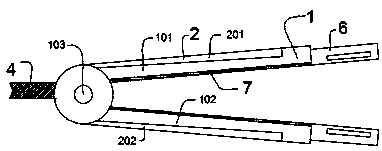

[0034] refer to figure 1 , Figure 4 Shown, one embodiment of the present invention is, a kind of fixture that is used for sofa cushion, bed sheet, comprises hinge 1, and above-mentioned hinge 1 comprises first clamping plate 101, second clamping plate 102, rotating shaft Part 103, the sofa cushion or bed sheet is usually made of cloth, and the hinge 1 of the hinge 1 should be flat when it is in the open / closed state. Therefore, the first clamping plate 101 and the second clamping plate 102 are in the open state. , the fabric A can be placed, and the first clamping plate 101 and the second clamping plate 102 can be attached to the fabric A in the folded state.

[0035] The above-mentioned hinge 1 is provided with at least two assembly grooves 2, and the above-mentioned assembly groove 2 is provided with a fixed pin 3, and the assembly grooves 2 are provided on the first clamping plate 101 and the second clamping plate 102 of the hinge 1 , when the hinge 1 is closed, by inser...

Embodiment 2

[0040] Based on the above-mentioned embodiment, another embodiment of the present invention is that in order to ensure the stability during the clamping process of the first clamping plate 101 and the second clamping plate 102, the above-mentioned assembly groove 2 includes a first clamping groove 201, a second Clamping groove 202, wherein the size of the first clamping groove 201 and the second clamping groove 202 are smaller than the size of the fixed pin 3; the first clamping groove 201 is located at the upper end of the first clamping plate 101, and the above-mentioned second clamping groove 202 is located at the second At the lower end of the clamping plate 102, the first clamping groove 201 and the second clamping groove 202 correspond to each other, wherein the first clamping groove 201 is the upper opening of the first clamping plate 101, and the second clamping groove 202 is the second clamping plate 102 lower ends are open.

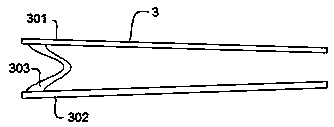

[0041] see figure 2 As shown, the above...

Embodiment 3

[0045] Based on the above-mentioned embodiment, another embodiment of the present invention is that in order to increase the stability of clamping, a flat splint 6 is provided on one side of the hinge 1, and the flat splint 6 includes an upper splint 601 and a lower splint 602; Wherein, the upper splint 601 and the lower splint 602 are T-shaped, so that the clamping range of the upper splint 601 and the lower splint 602 can be increased as much as possible, so as to avoid curling caused by simply using the hinge 1 for clamping.

[0046] The upper splint 601 is connected to the head end of the first clamping plate 101, the lower splint 602 is connected to the head end of the second clamping plate 102, the upper end of the lower splint 602 is at the same level as the upper surface of the second clamping plate 102, and the upper splint 601 The lower end is in the same horizontal plane as the lower surface of the first clamping plate 101, and the contact surface is evenly contacted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com