Milling cutter clamping device

A technology of clamping device and milling cutter, applied in the field of milling cutter clamping device, can solve the problems of slow replacement of milling cutters and reduced processing efficiency of parts, and achieve good clamping effect, increase clamping area, and avoid loosening. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following is further described in detail through specific implementation methods:

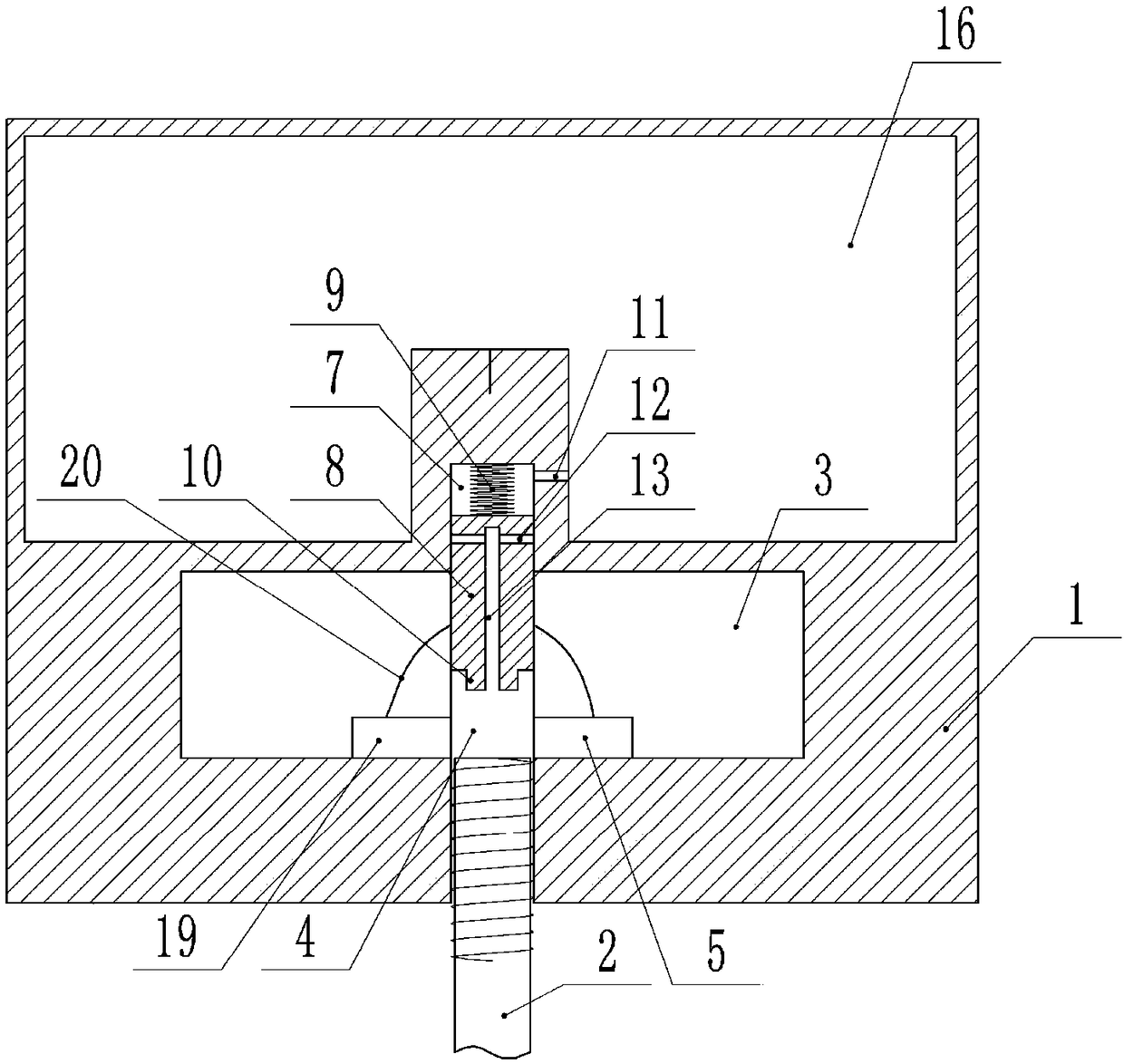

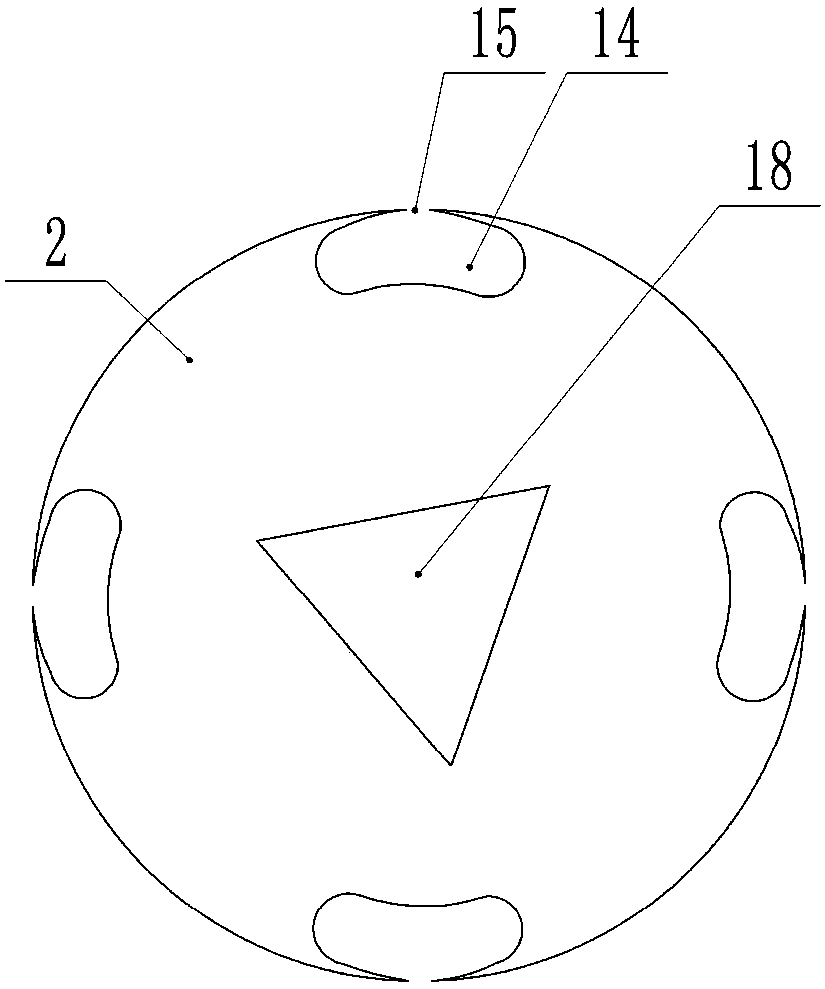

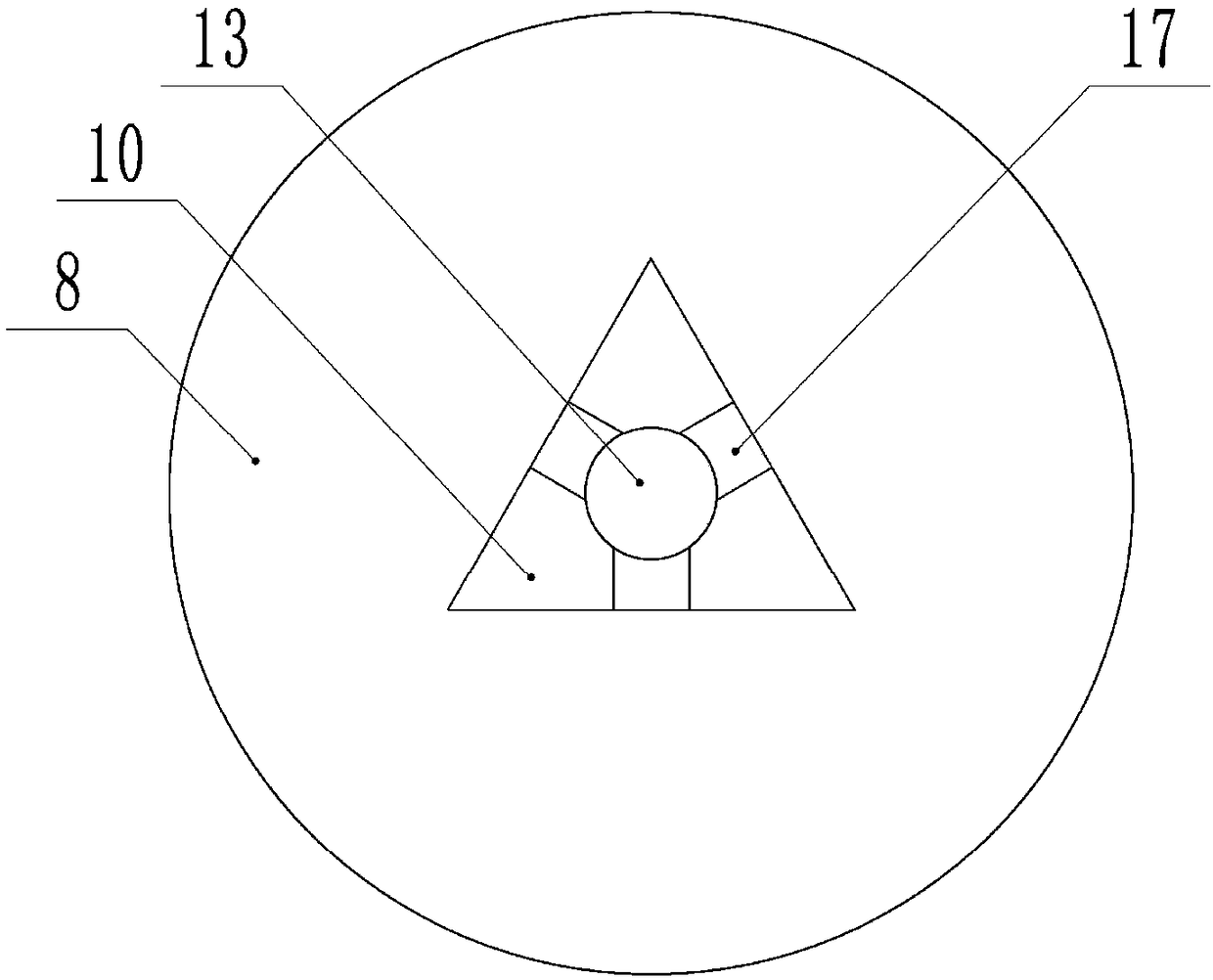

[0020] The reference signs in the drawings of the description include: clamping head 1, cutter head 2, horizontal groove 3, vertical groove 4, sleeve 5, pawl 6, sliding hole 7, slider 8, spring 9, protrusion 10, Through hole 11, water inlet hole 12, middle hole 13, through groove 14, notch 15, cavity structure 16, water guide groove 17, groove 18, string 20, protruding tooth 21.

[0021] Such as figure 1 and Figure 4 As shown, a milling cutter clamping device includes a clamping head 1 and a cutter head 2. The lower part of the clamping head 1 is processed with a cross-shaped installation groove. The installation groove includes a horizontal groove 3 and a vertical groove 4. The horizontal groove 3 is left and right. Sleeves 5 are respectively installed on the sides through bearings, the outer side of the sleeve 5 is processed with threads, the inner side of the sleeve 5 is proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com