Method for manufacturing inner buckle flange of wind power blade web die

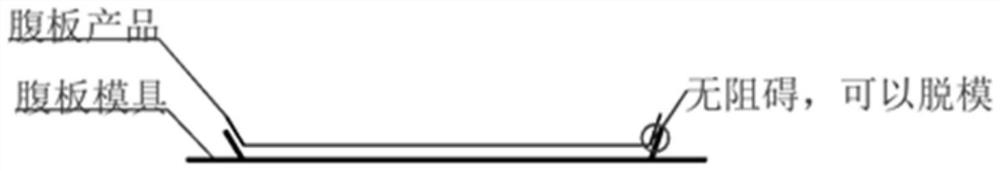

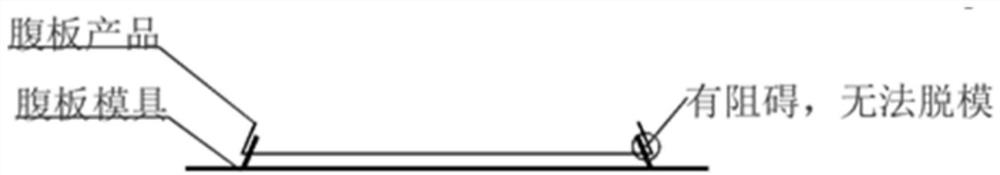

A manufacturing method and technology of wind power blades, which can be applied to household appliances, other household appliances, household components, etc., can solve the problem that the ribs cannot be demoulded, etc., and achieve the effect of increasing the workload and giving full play to the space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in more detail below with reference to the examples and the drawings, but the embodiments of the present invention are not limited thereto.

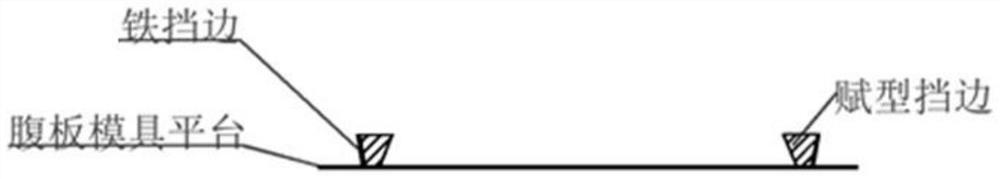

[0016] This example discloses a buckle baking fabric method for wind power blade web mold, which is made on a web mold platform (i.e., iron platform), and needs to be configured with iron baffling and assault baffling. See image 3 As shown, in which the iron baffle is used in the positioning of the assault baffling, the impeller baking edge is the final web mold baking, and the gear edge can maintain a certain shape, and the overall is soft, the web product is molded. It can be brought together, so the web is not covered by the card in the web mold. The method of making the buckle bench is as follows:

[0017] First, scribe

[0018] Take a point on the iron platform to pull out the contour of the web, the contour of the web is offset from the outside, which is a baking positioning line.

[0019]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com