Plant fibre wire coil of wire with integral structure and pressing method and special mold thereof

A technology of plant fiber and overall structure, which can be applied to other home appliances, home appliances, applications, etc., can solve the problems of high cost of molded products, widespread use of unfavorable products, and many preparation procedures, so as to achieve low production costs and solve the problems that cannot be removed. Molding problem, effect of reducing preparation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Such as Figure 4 As shown, the integrated plant fiber steel wire reel of the present invention includes disc plates connected to both ends of the reel, and is characterized in that the reel 8 has no joints in the axial direction and is an integral structure.

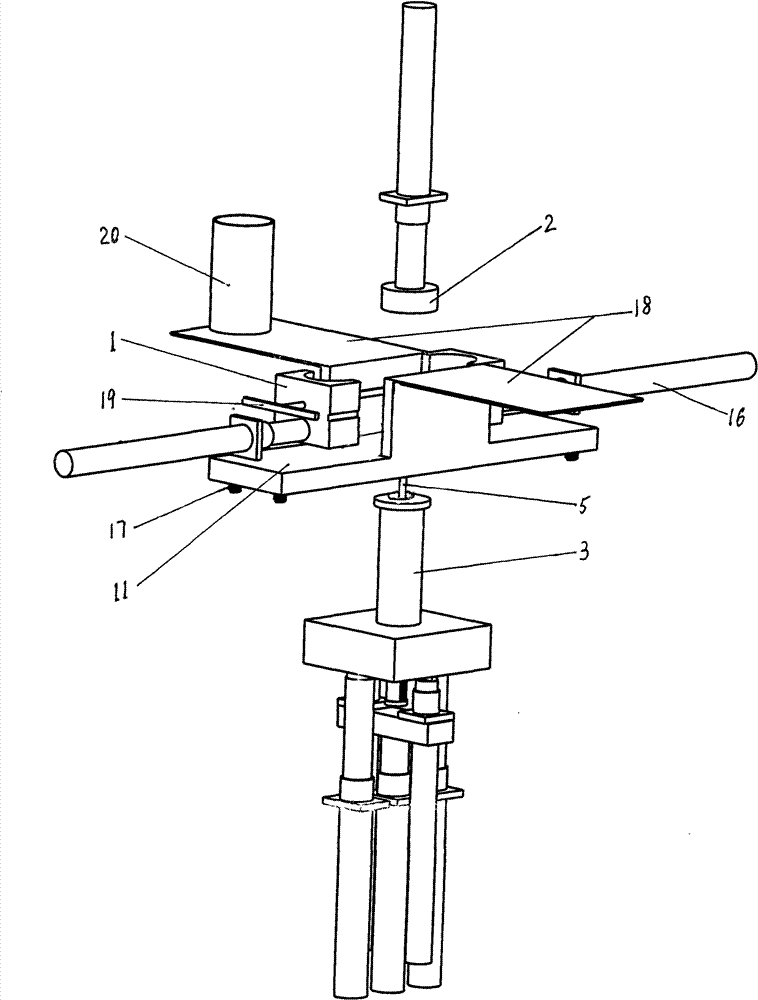

[0023] Such as figure 1 As shown, the special mold for the plant fiber steel wire reel with integral structure includes a female die, an upper die punch, a lower die punch, a core rod movably connected with the lower die punch, and a power device.

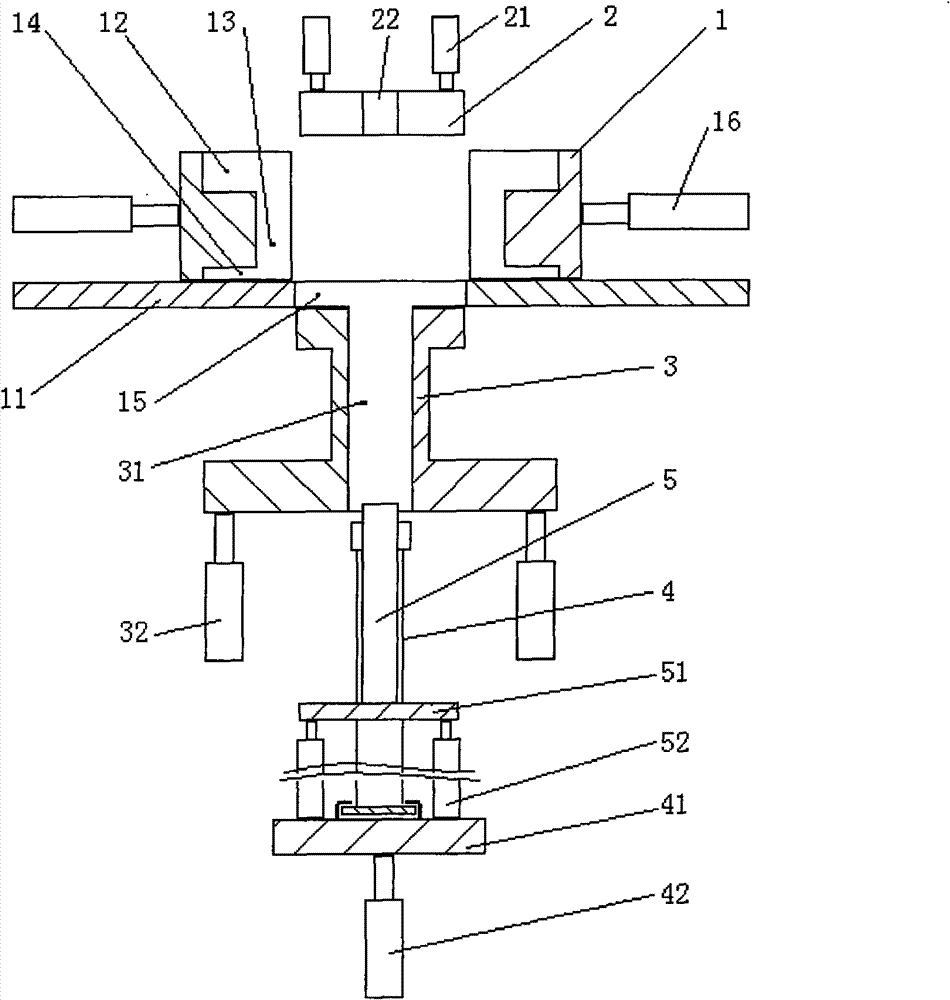

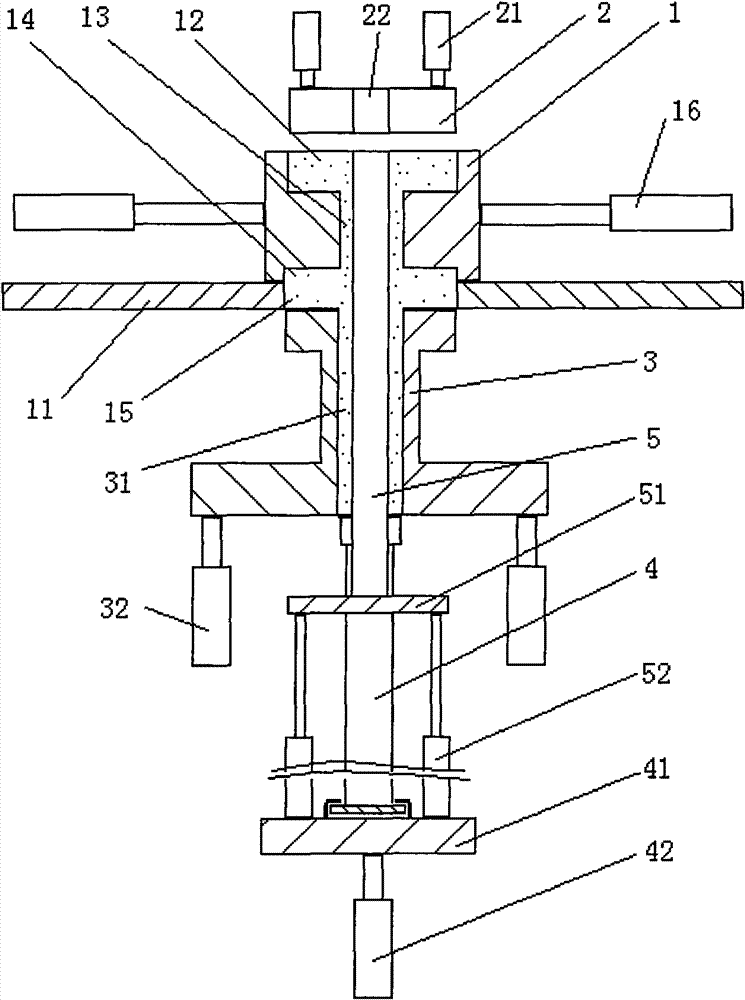

[0024] Such as figure 2 , 3 As shown, the female mold 1 is provided with a female mold frame 11, and the female mold frame 11 is provided with a cavity hole 15 communicating with the cavity of the female mold 1; The cavities 14 are of equal diameter. Such as figure 2 , 3 As shown, the female mold 1 is divided into two by the central axis, and the two parts are symmetrical, and are respectively provided with a power device 16, and a part thereof is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com