Device applied to pushing demoulding of fore shaft pipe of diaphragm wall

A locking pipe and jacking technology, which is applied in the direction of sheet pile walls, buildings, and infrastructure engineering, etc., can solve the problems of locking pipe inclination, slurry leakage, excess frictional resistance and mechanical bite force, etc., and achieves simple structure and reduced use Cost, effect of reducing water seepage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the purpose and features of the present invention more comprehensible, the specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings.

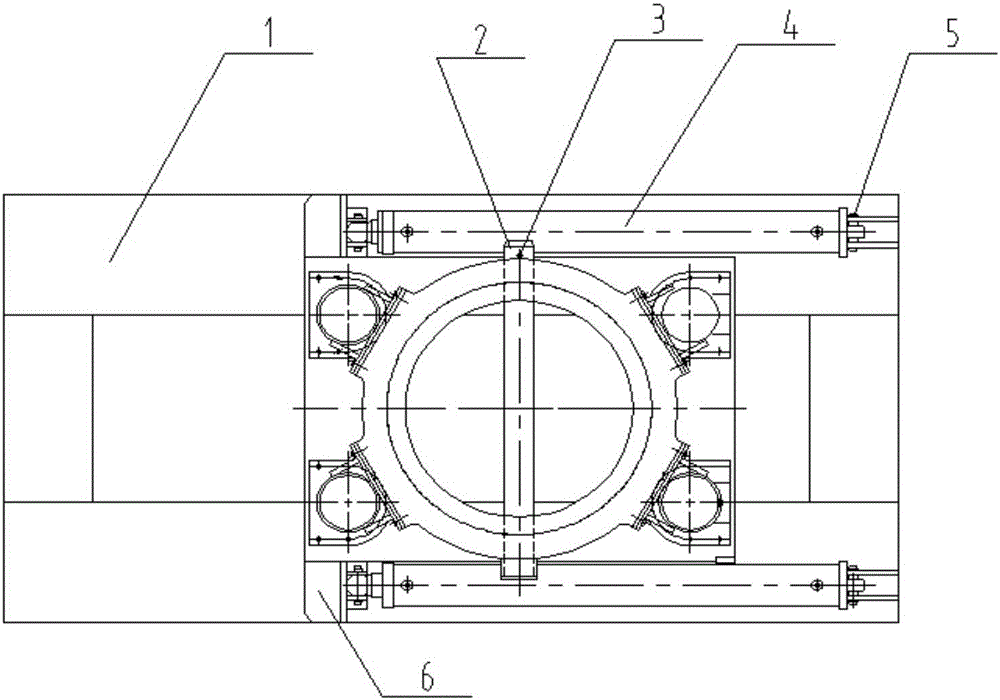

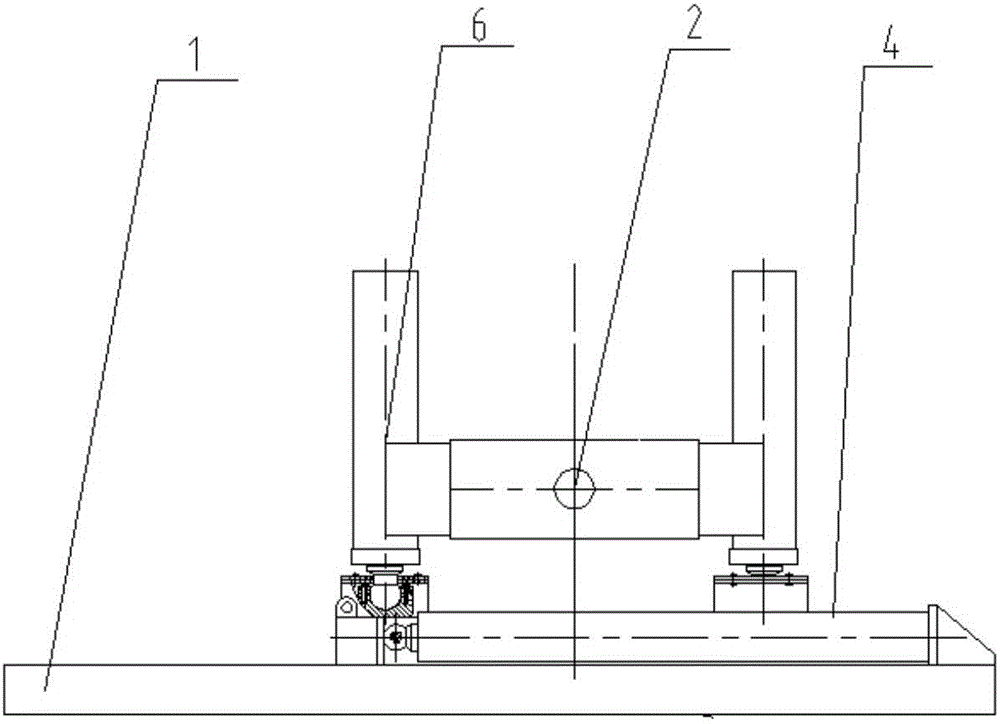

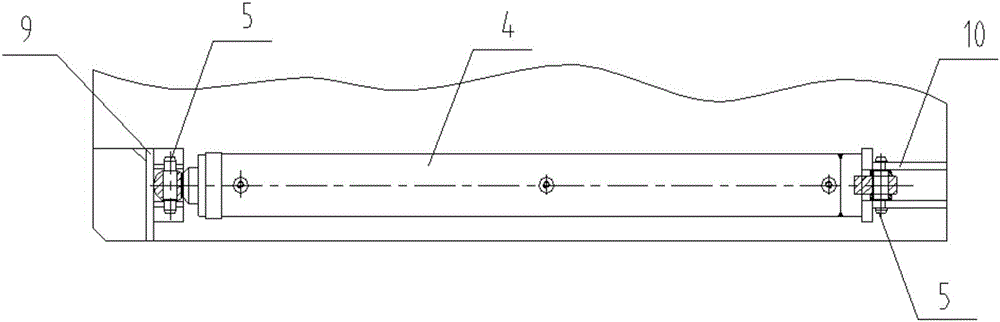

[0024] Such as Figure 1 to Figure 4 As shown in the figure, a device for ejecting and demoulding the locking pipe of the ground wall includes a locking pipe lifting and pushing bottom beam frame, a locking pipe ejecting device, and a horizontal pushing device.

[0025] The locking tube pulls and pushes the bottom beam frame 1. It is placed on a stable foundation and plays a supporting role. At the same time, the upper surface of the bottom beam frame is the sliding surface of the horizontal push of the device, and the maximum static friction force of the lower surface is greater than that of the upper surface. friction, so that the whole device can be placed stably.

[0026] The locking pipe jacking device includes a locking pipe jacking mach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com