Nuclear power station wafer butterfly valve on-site pressing tool and pressing system

A technology for wafer butterfly valves and nuclear power plants, which can solve the problem of easily damaged flange sealing surfaces and valve seats and large-diameter valves by detecting the appearance of fluid at the leakage point, measuring the increase and decrease rate of the fluid, and measuring devices. Inconvenient transportation, damage to equipment and personnel, etc., to achieve the effect of effectiveness and practicability, convenient suppression, and high availability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

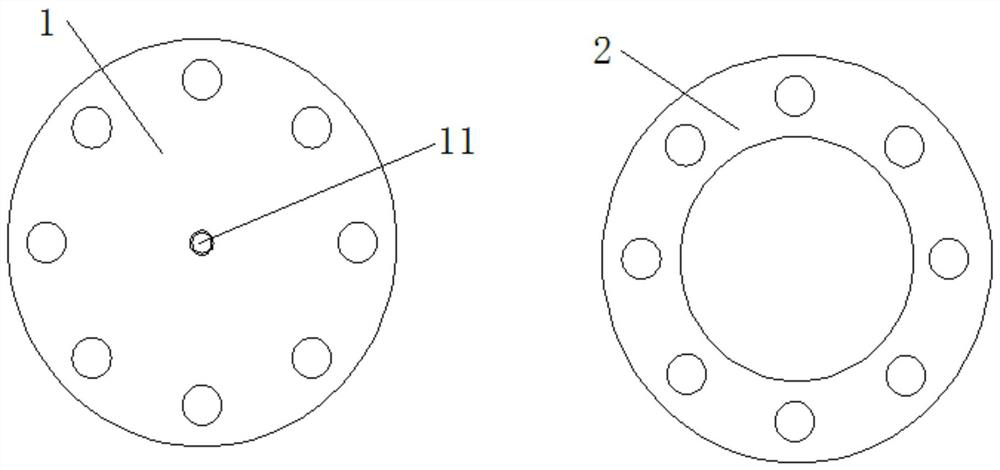

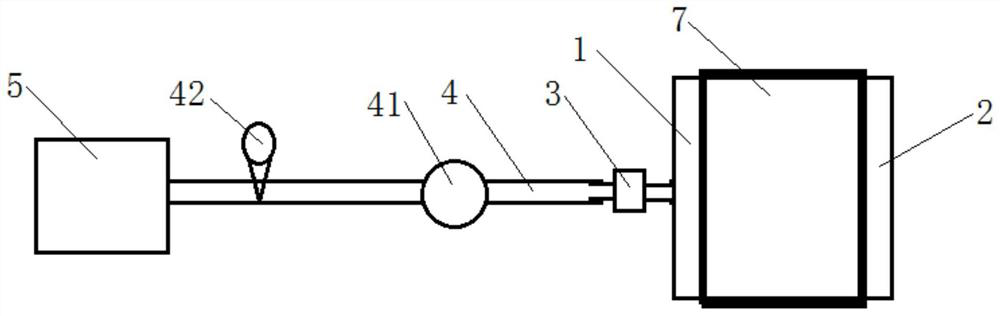

[0034] refer to figure 1 , this embodiment provides an on-site pressing tool for the wafer butterfly valve of a nuclear power plant, which is used for in-situ pressing of the wafer butterfly valve of a nuclear power plant. The flange 1 on the side of the blocking plate and the flange ring 2 on the draining side clamp the wafer butterfly valve of the nuclear power plant in the middle. The bolt hole of the clip butterfly valve is provided with a joint threaded hole 11 for externally connecting the double-headed outer wire joint in the middle, and the flange ring 2 on the exhaust side is a ring structure, and a bolt hole for connecting the clip butterfly valve of the nuclear power plant is provided on it.

[0035] In this embodiment, the size of the flange 1 on the blocking plate side and the flange ring 2 on the venting side are adapted to the caliber of the wafer butterfly valve in a nuclear power plant, and multiple sets can be designed according to the caliber of different va...

Embodiment 2

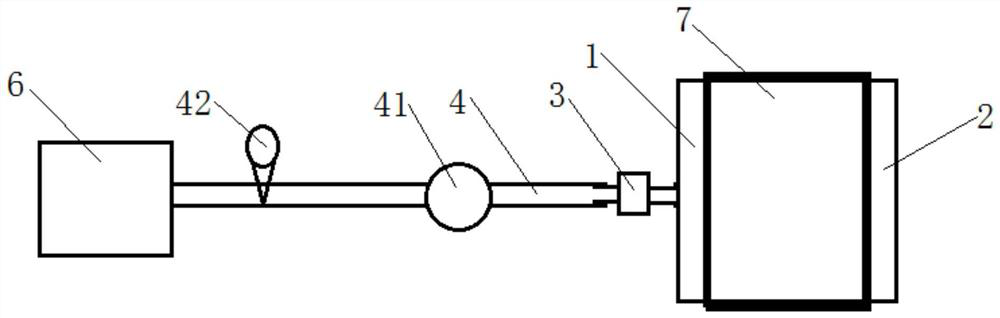

[0046]The difference from Embodiment 1 is that this embodiment provides another on-site pressing system for wafer butterfly valves of nuclear power plants, which is used for on-site pressing of wafer butterfly valves in nuclear power plants. The pressing system includes pressing tools, double-headed outer wire joints 3 , pressing the pipeline 4 and the compressor 6, the pressing tool includes a flange 1 on the side of the blocking plate and a flange ring 2 on the emptying side, and the flange 1 on the side of the blocking plate and the flange ring 2 on the emptying side are connected by bolts The two ends of the wafer butterfly valve 7 of the nuclear power plant to be tested, the flange plate 1 on the side of the blocking plate and the flange ring 2 on the venting side clamp the wafer butterfly valve of the nuclear power plant in the middle, and one end of the double-headed outer wire joint 3 is connected to the flange on the side of the blocking plate. The joint threaded hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com