Multilayer inconsistent medium interface stripping damage detection method based on ultrasonic energy diffusion

An ultrasonic energy and damage detection technology, applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, measuring devices, etc. and shape details information, the difficulty of analysis and identification of small detachment damage, etc., to achieve the effect of accurate and precise identification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the following embodiments in no way limit the present invention.

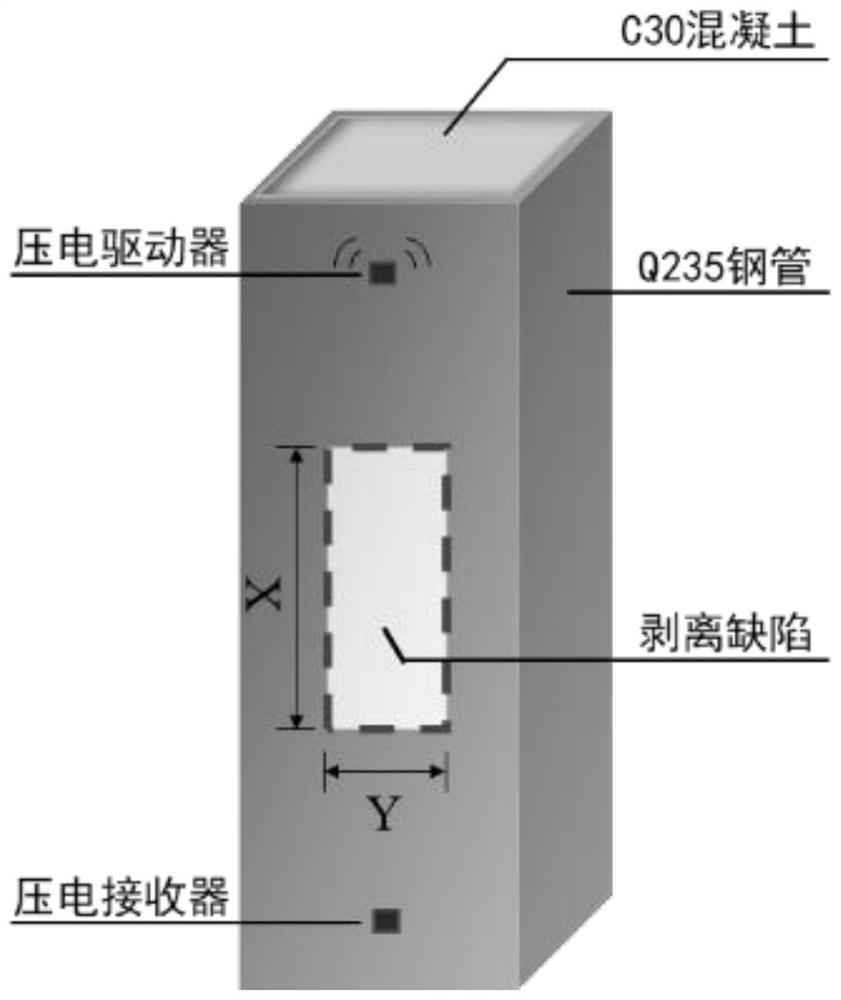

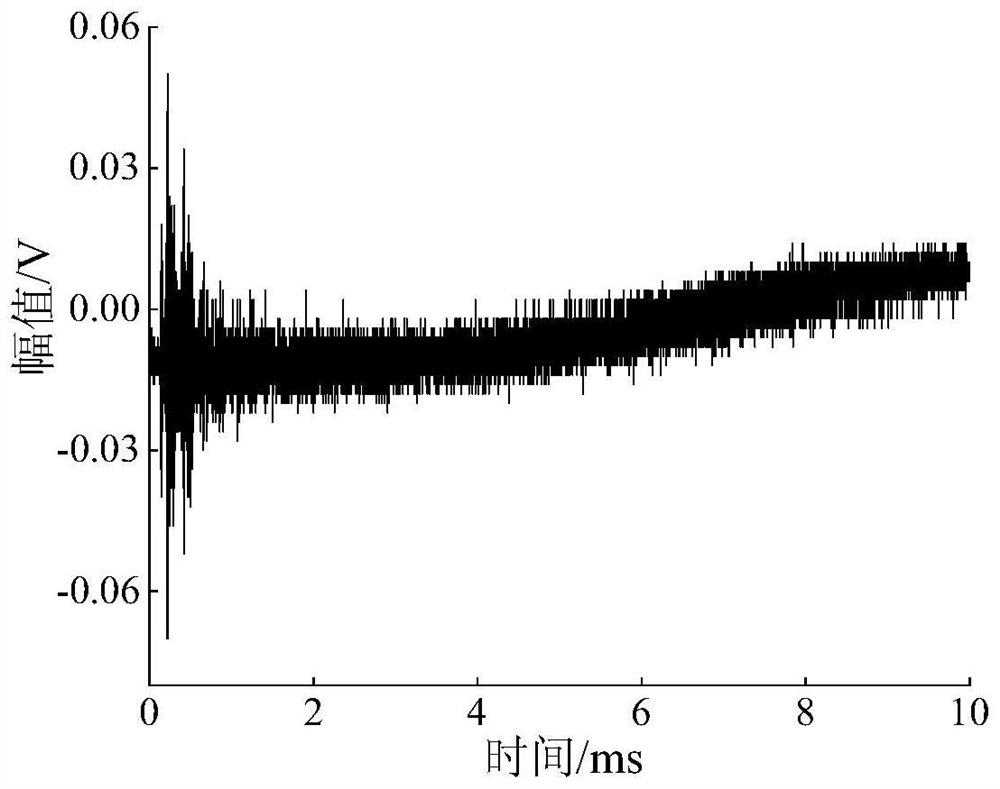

[0048] The present invention proposes a detection method based on ultrasonic energy diffusion multi-layer non-uniform medium interface peeling damage, such as Figure 8 As shown, in the specific implementation case, the model specimens with different interface detachment damage conditions are designed, and the frequency window energy is calculated by pane division and time-frequency Fourier transform of the echo signal received by the piezoelectric sensor. The information is extracted and combined, based on the three-dimensional ultrasonic energy diffusion equation, data fitting is performed on the total energy of the combined frequency window, the damage characterization parameters ultrasonic energy diffusion coefficient D and dissipation coefficient σ are solved, and normaliz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com