Integrated directional immersion cooling type server module and data center

A server module, immersion cooling technology, applied in cooling/ventilation/heating retrofit, electrical components, electrical equipment structural parts, etc., can solve problems such as inconvenient maintenance operations, large coolant consumption, and water-cooling plate leakage, saving The effect of space, reducing particle size and increasing flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

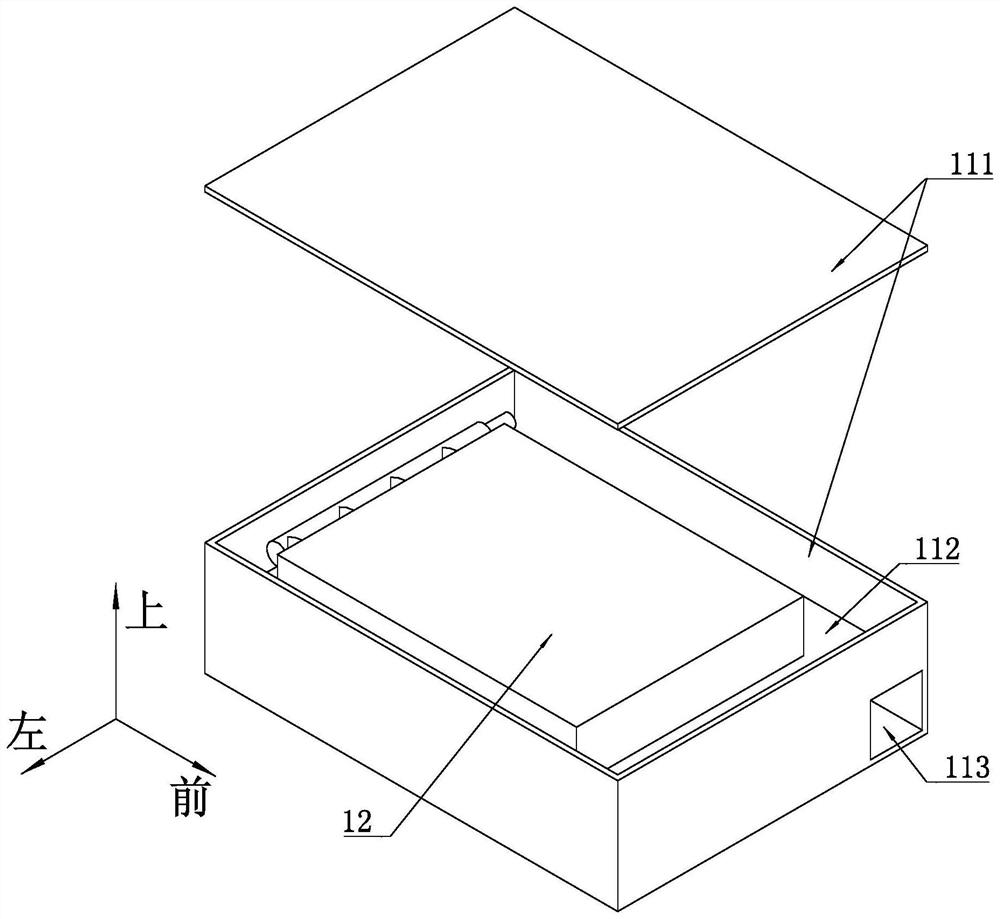

[0061] For the convenience of description, the coordinate system is defined as figure 1 , and the left-right direction is horizontal, the front-back direction is vertical, and the up-down direction is vertical.

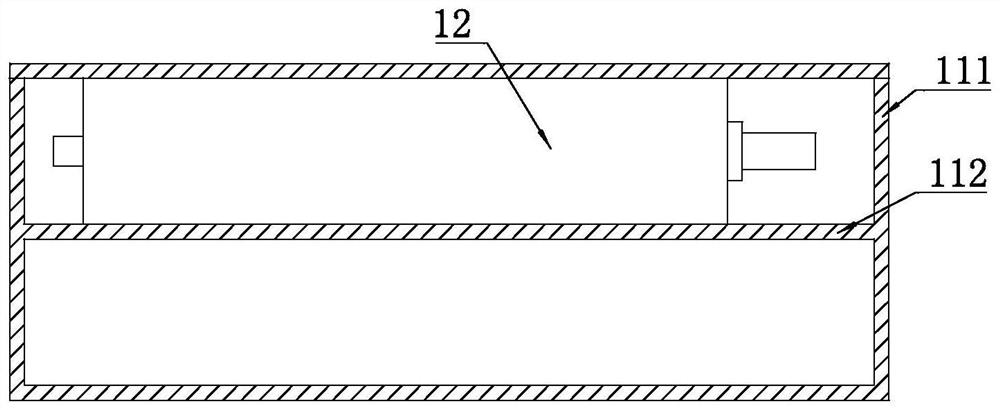

[0062] Such as figure 1 and figure 2 As shown, an integrated directional immersion cooling server module includes a main box body 111, a first partition 112 is arranged inside the main box body 111, and the first partition plate 112 divides the main box body 111 The internal space of the building is divided into upper and lower parts that are not connected to each other, namely the upper space and the lower space. The server 12 is fixedly arranged in the upper space, that is, the server 12 is packaged in the upper space of the main box 111 . An air inlet 113 is arranged on the front side wall of the lower space, and an air outlet is arranged on the right side wall of the lower space.

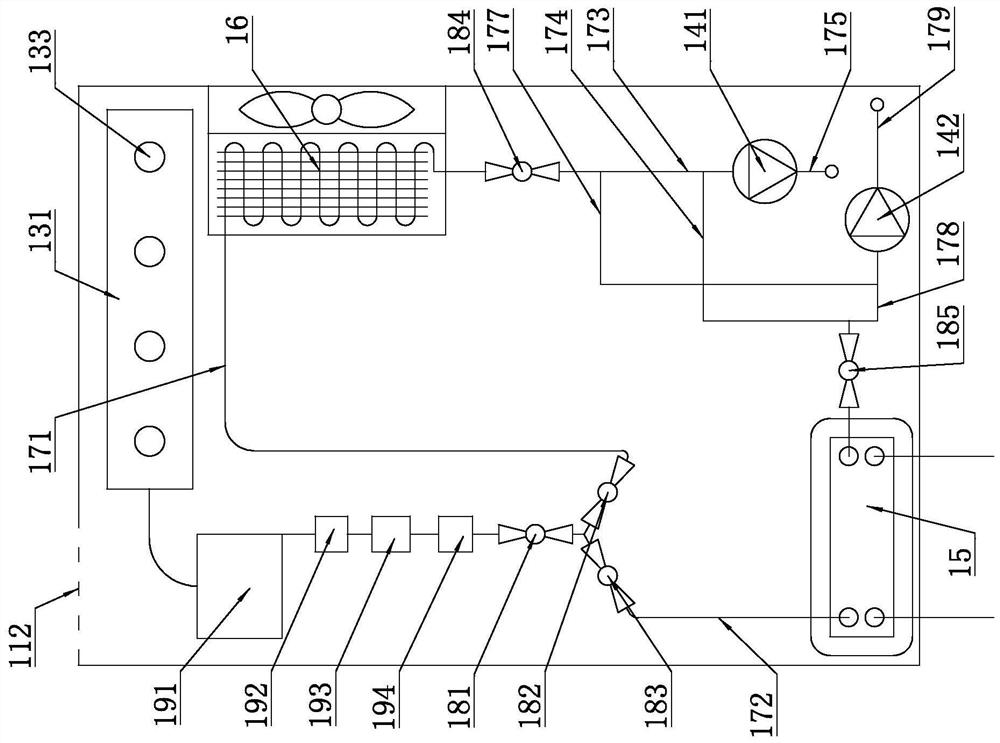

[0063] Such as image 3 As shown, a first liquid return pipe 131 , a first ci...

Embodiment 2

[0078] Such as Figure 11 As shown, a data center using an integrated directional immersion cooling server module includes a main frame body 2. As a specific implementation, the main frame body 2 described in this embodiment includes a rectangular parallelepiped frame, and the rectangular parallelepiped frame A plurality of support frames are arranged inside, and the server module 1 is arranged on the support frame, and the server module 1 is fixedly connected with the support frame by screws.

[0079] The rear side of the main frame body 2 is provided with an installation box 21 , and the rear side of the installation box 21 is provided with a second air-cooled radiator 4 . The installation box 21 is provided with a water inlet pipe 51 and an outlet pipe 52 extending vertically, and the secondary side inlet of the plate heat exchanger 15 of the server module 1 is connected to the first pipe 61 through the first pipe 61. The water inlet pipe 51 is connected to each other, and...

Embodiment 3

[0085] Such as Figure 12 As shown, the second air-cooled radiator 4 is placed outside the installation box 21, and the rest of the structure is the same as that of the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com