Metal round pipe contracting equipment

A metal and tube shrinking technology is applied in the field of equipment for reducing the diameter of metal round tubes, which can solve the problems affecting the safety of PTC heating tubes, affecting the appearance of metal tubes, and uneven strength of metal tubes, so as to maintain smoothness and convenience. Independent operation, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

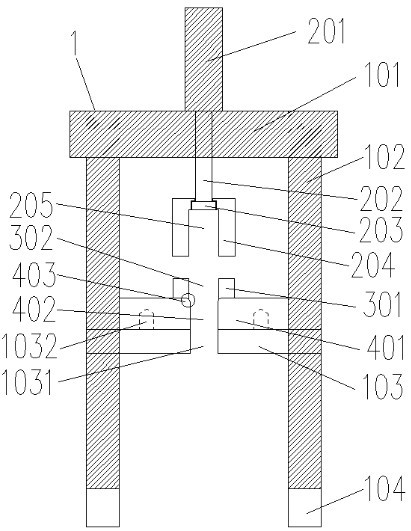

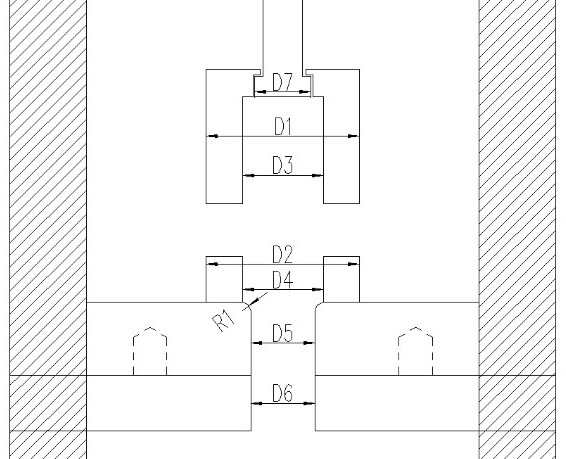

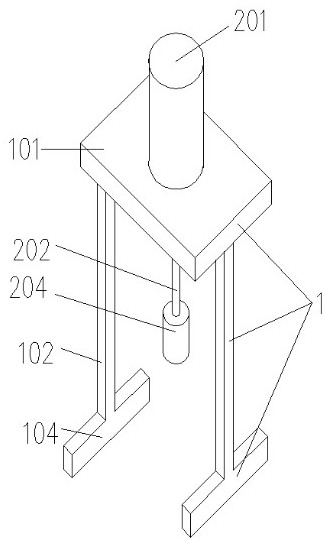

[0019] A kind of metal round pipe shrinking equipment of the present invention is further described below with reference to accompanying drawing:

[0020] Such as figure 1 , 2 , shown in 3 and 4, a metal round pipe shrinking equipment, comprising: a door frame 1 and an oil pressure device 201 fixed on the top of the door frame 1, the piston on the bottom surface of the oil pressure device 201 is fixedly connected to the metal Press bar 202, the bottom end of the metal press bar 202 is clamped with an upper positioning mold 204 for maintaining the vertical position of the metal tube; the middle part of the door frame 1 is provided with a lower mold assembly, and the lower mold assembly It includes a shrinking mold 401 for shrinking the tube and a lower positioning mold 301 arranged on the shrinking mold 401 for placing the metal round tube.

[0021] As a further improvement of the present invention, two supporting columns 102 are provided on both sides of the door-shaped fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com