Chain plate telescopic machine

A technology of telescopic machine and telescopic mechanism, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., which can solve problems such as belt damage, belt deviation, and high belt cost, and achieve strong bearing capacity, prevent deviation, and rigidity Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

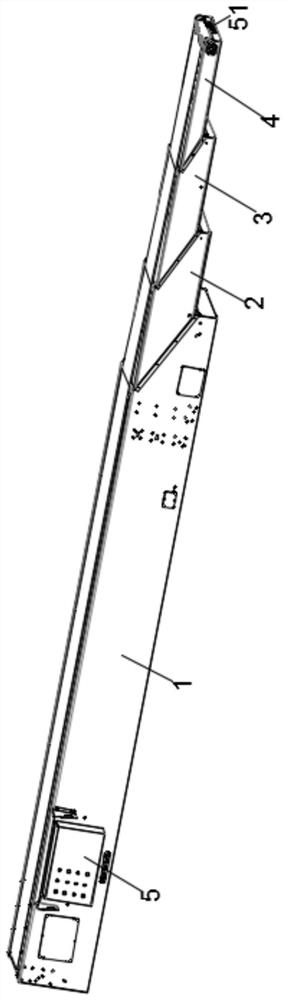

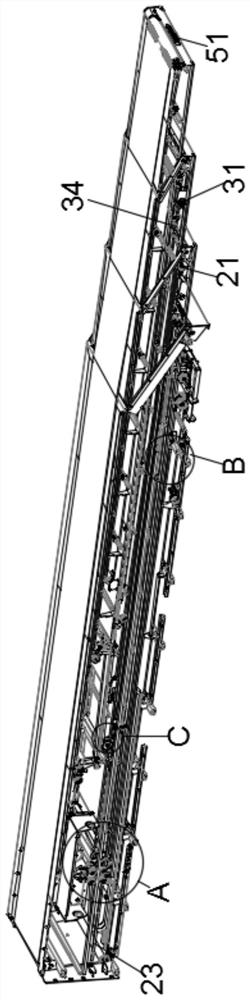

[0032] See attached Figure 1 to Figure 15 As shown, a chain plate telescopic machine in this embodiment is composed of a fixed bracket 1, a telescopic mechanism, and a conveying device. The telescopic mechanism is installed in the fixed support 1. A control cabinet 5 is provided on the outside of the fixed support 1, and an operation button 51 is provided at the front end of the telescoping mechanism for on-site personnel to operate.

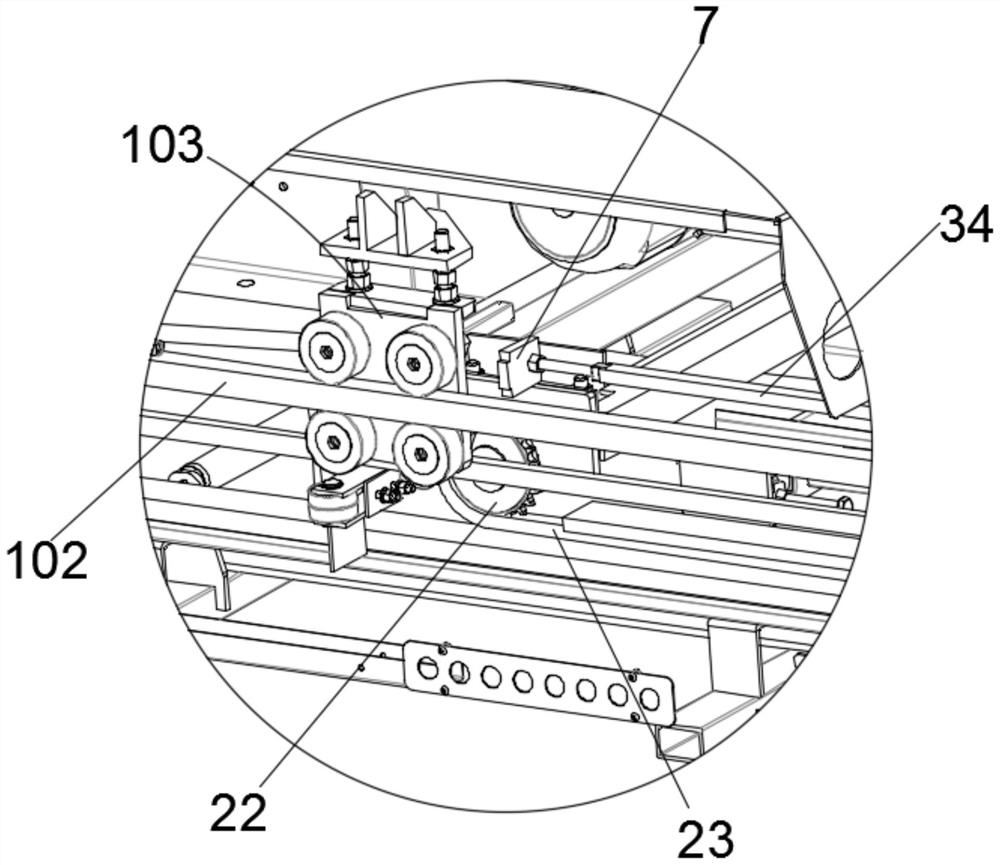

[0033] The fixed bracket 1 includes a fixed shell 11, the upper end of the fixed shell 11 is provided with a universal supporting plate 12, and the protruding end of the fixed shell 11 has an opening 13 for placing the telescopic mechanism. The protruding end of the fixed housing 11 is provided with a supporting wheel assembly 6 . Such as Figure 15 As shown, the support wheel assembly 6 includes a support base 61 and guide wheels 62 arranged at both ends of the support base.

[0034] The telescopic mechanism includes a first telescopic sec...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap