Oil sludge conveying screw pump with anti-blocking function for oil field

A technology for conveying screw and sludge, which is applied to mixers with rotary stirring devices, rotary piston type/swing piston type pump components, rotary piston pumps, etc., which can solve the problem of low service life, easy blockage, and transportation Poor efficiency and other problems, to achieve high-efficiency conveying, avoid material breakage, and improve service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

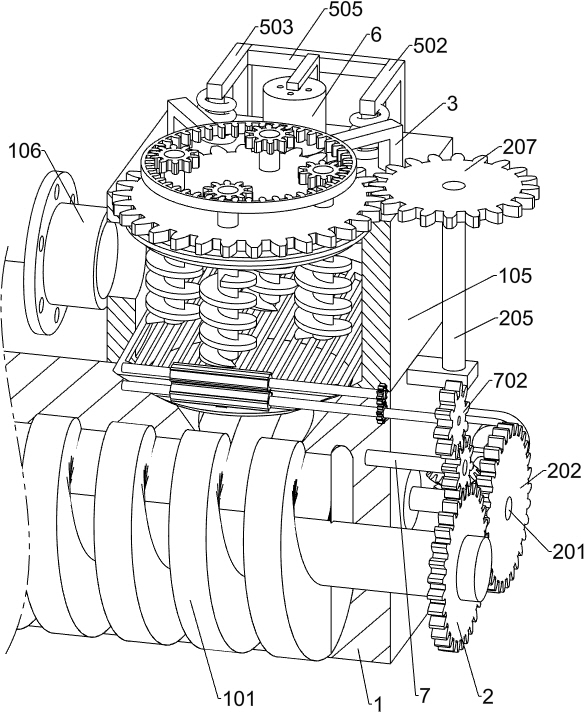

[0033] A screw pump for transporting sewage sludge in oil fields with anti-clogging function, such as Figure 1-3 As shown, it includes a housing 1, a first screw 101, a second screw 102, a base 103, a drive motor 104, an intermediate compartment 105, a material inlet 106, a material outlet 107, an agitating mechanism, a power mechanism, an induction mechanism, and a discharge mechanism. Air mechanism and crushing mechanism, the first screw 101 and the second screw 102 are rotated in the housing 1, the first screw 101 and the second screw 102 are engaged, the right end of the housing 1 is fixed with a base 103, and the upper end of the base 103 is fixed There is a driving motor 104, the output shaft end of the driving motor 104 is fixedly connected to the right end of the first screw 101, the upper surface of the right part of the housing 1 is fixedly connected to the middle compartment 105, the left end of the middle compartment 105 is fixedly connected to the feed port 106, a...

Embodiment 2

[0037] On the basis of Example 1, such as Figure 4 and Figure 5 As shown, the stirring mechanism includes a first spur gear 2, a first transmission shaft 201, a second spur gear 202, a first helical gear 203, a first fixed frame 204, a second transmission shaft 205, a second helical gear 206, a first Three spur gears 207, gear turntable 208, rotating shaft 209 and push assembly, the first spur gear 2 is affixed to the right end of the first screw rod 101, the first transmission shaft 201 is affixed to the right end of the second screw rod 102, the right end of the first transmission shaft 201 A second spur gear 202 is fixedly connected, and the second spur gear 202 meshes with the first spur gear 2. The right part of the first transmission shaft 201 is fixedly connected with a first helical gear 203, and the first helical gear 203 is located on the left side of the second spur gear 202. The right end of the housing 1 is fixedly connected with a first fixed frame 204, and th...

Embodiment 3

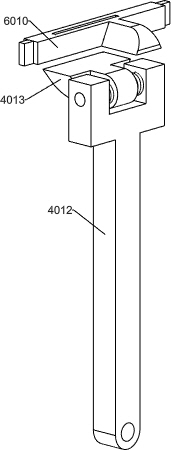

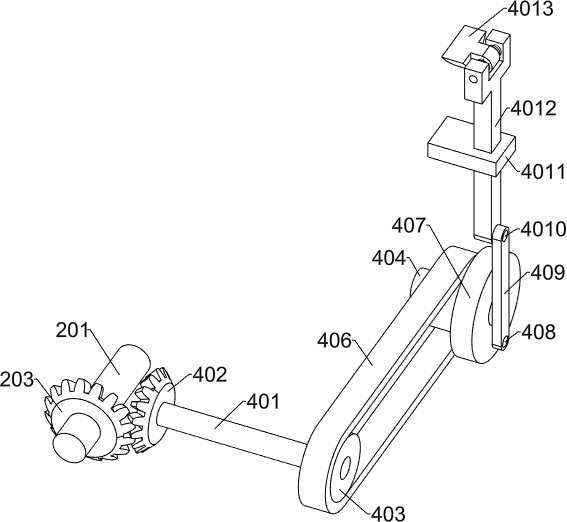

[0044] On the basis of Example 2, such as Image 6 and Figure 7 As shown, the power mechanism includes a second fixed frame 4, a third transmission shaft 401, a third helical gear 402, a first pulley 403, a first rotating shaft 404, a second pulley 405, a belt 406, a runner 407, a second Two rotating shafts 408, movable rod 409, the third rotating shaft 4010, the third fixed mount 4011, the first sliding rod 4012 and the rotating block 4013, the upper surface of the rear part of the base 103 is fixedly connected with the second fixed mount 4, the second fixed mount 4 top A third transmission shaft 401 is provided for rotation, and the front end of the third transmission shaft 401 is fixedly connected with a third helical gear 402, the third helical gear 402 meshes with the first helical gear 203, and the rear end of the third transmission shaft 401 is fixedly connected with a first belt Wheel 403, the rear surface of the housing 1 is rotated with a first shaft 404, the rear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com