Double-floating type mounting structure of connector socket

A connector socket and installation structure technology, which is applied to the parts, connections, coupling devices, etc. of the connection device, can solve the problems that cannot meet the requirements of the special use environment, the installation screws cannot be installed smoothly, and the installation screws cannot be installed, etc. , to prevent water and dust from entering the connector and inside the cabinet, protect the cabinet equipment, and achieve low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

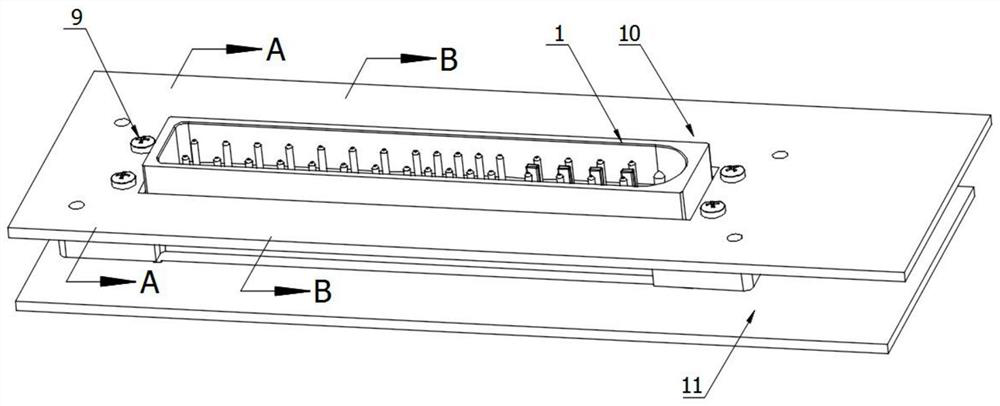

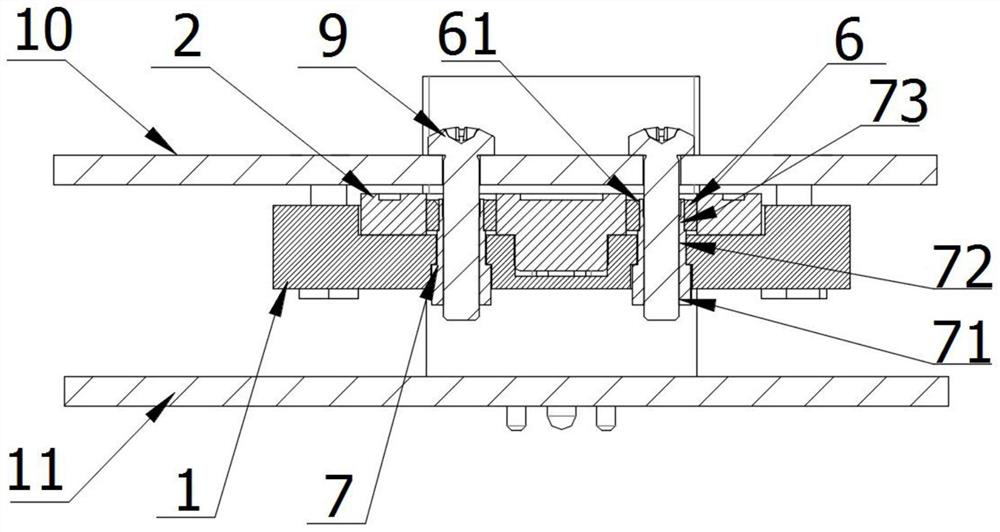

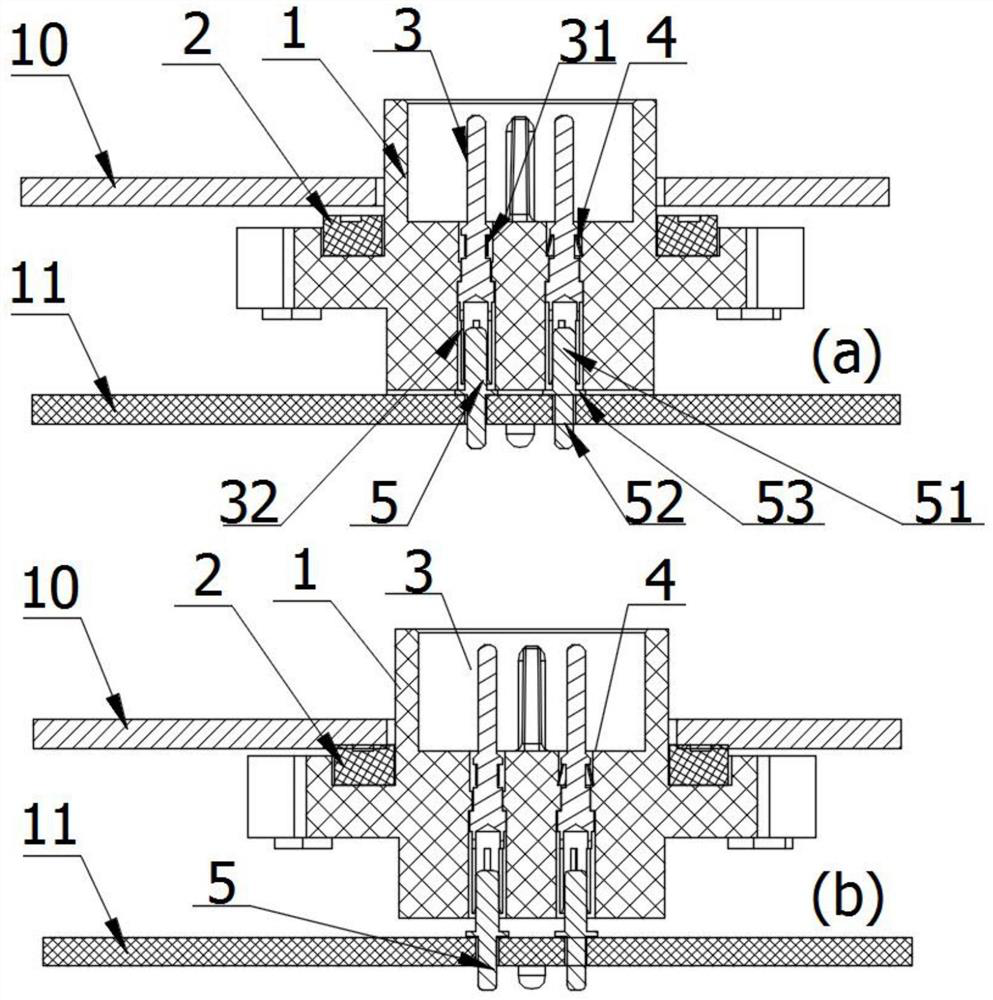

[0036] Such as figure 1 , figure 2 , Figure 4 , Image 6 As shown, this embodiment is a double-floating installation structure of a connector socket, including a socket, a cabinet panel 10, a gasket 6 and a floating riveting tube 7, the socket includes a base 1, and a fixed riveting tube 8 is arranged on the base 1 , the base 1 is sequentially set with a gasket 2 and a cabinet panel 10 from bottom to top, and the same mounting screw 9 is movably inserted in the through hole opened on the gasket 2 and the cabinet panel 10, the base 1, the gasket 2, The mounting screws 9 and the cabinet panel 10 constitute a floating contact structure;

[0037] In the floating structure of the contact piece: the base 1 is socketed with the gasket 2 and the cabinet panel 10, and the mounting screw 9 penetrates through the through holes on the cabinet panel 10 and the gasket 2 to thread the floating riveting tube 7; the mounting screw 9 makes the socket and When the cabinet panel 10 is tight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com