Positioning-hole-free film-pasted PCB routing technology

A PCB board, non-positioning technology, applied in the direction of circuit board tool positioning, electrical components, insulating substrate/layer processing, etc., can solve the problems of no support conditions, human respiratory system damage, etc., to ensure respiratory health and enhance safety performance, the effect of improving practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

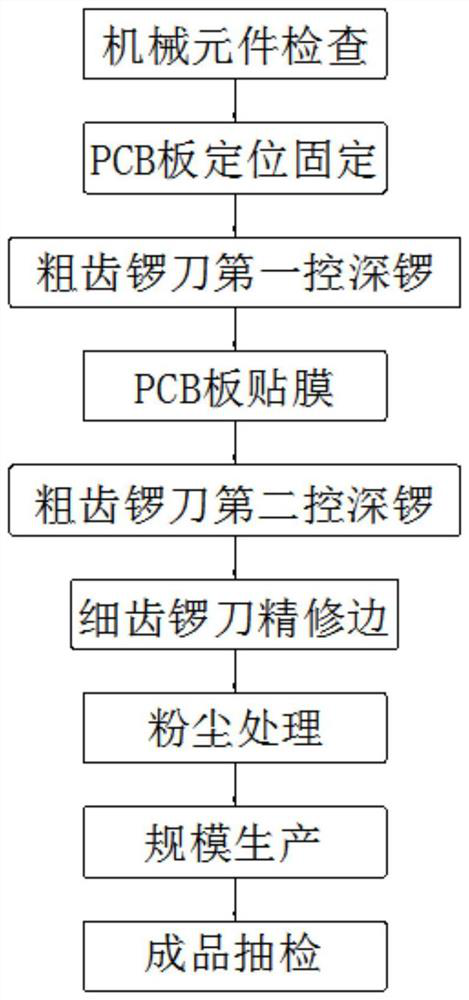

[0050] A film-attached PCB gong board technology without positioning holes, comprising the following steps:

[0051]S1: Mechanical component inspection: Before using the PCB gong machine, check whether the tools, motors and other equipment of the PCB gong machine are in normal condition, and check the front and rear safety door micro switch sensors and emergency stop buttons of the gong machine, Ensure the safety of subsequent gongs and boards;

[0052] S2: PCB board positioning and fixing: through the cooperation of the existing positioning holes on the edge of the PCB board and the existing positioning pins, the PCB board is fixed on the table of the gong board machine to realize the positioning operation of the PCB board;

[0053] S3: Coarse-tooth gong knife first control deep gong:

[0054] S31: Gong knife parameter setting: through the control panel on the PCB gong board machine, input the PCB board positioning data, and set the processing parameters, set the tool type, ...

Embodiment 2

[0072] A film-attached PCB gong board technology without positioning holes, comprising the following steps:

[0073] S1: Mechanical component inspection: Before using the PCB gong machine, check whether the tools, motors and other equipment of the PCB gong machine are in normal condition, and check the front and rear safety door micro switch sensors and emergency stop buttons of the gong machine, Ensure the safety of subsequent gongs and boards;

[0074] S2: PCB board positioning and fixing: through the cooperation of the existing positioning holes on the edge of the PCB board and the existing positioning pins, the PCB board is fixed on the table of the gong board machine to realize the positioning operation of the PCB board;

[0075] S3: Coarse-tooth gong knife first control deep gong:

[0076] S31: Gong knife parameter setting: through the control panel on the PCB gong board machine, input the PCB board positioning data, and set the processing parameters, set the tool type,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com