Black tea processing method, processing equipment and black tea

A processing method and technology for black tea, applied in the direction of pre-extraction tea treatment, etc., can solve the problems of dark color of tea soup, sour taste, and insignificant floral fragrance, and achieve high controllability, strong operability, and ensure quality stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0040] Such as figure 1 Shown, the invention provides a kind of black tea processing method, it comprises the following steps of carrying out in sequence:

[0041] Withering the fresh leaves, under the conditions of preset temperature and preset humidity, withering the fresh tea leaves to obtain the withered tea leaves with the first preset water content;

[0042] Tea leaves are evenly watered, and the withered tea leaves are wrapped and placed in a light-proof and ventilated place, and left to stand for a preset time to obtain evenly watered tea leaves with reddish veins;

[0043] Kneading the tea leaves, kneading the evenly watered tea leaves to obtain tea embryos with completely reddened leaves;

[0044] The tea leaves are dried, and the tea germ is dried.

[0045] The black tea processing method of the present invention removes the fermentation process in the traditional black tea processing steps, does not need to set up a fermentation device to carry out the fermentati...

Embodiment approach 2

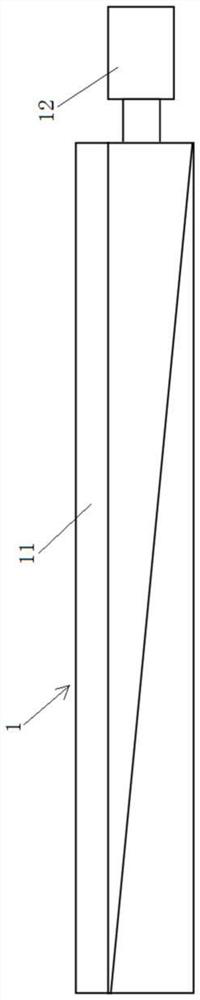

[0077] Such as figure 2 , image 3 , Figure 4 as well as Figure 8 As shown, the present invention provides a kind of black tea processing equipment, comprising: wilting device 1, which is used to wilt fresh tea leaves to obtain wilted tea leaves; The uniform water tea leaves with red veins; the kneading device 3 is used to knead the uniform water tea leaves to obtain tea embryos with completely red leaves; the tea drying device is used to dry the tea embryos. Its working principle and beneficial effects are the same as those of the black tea processing method in Embodiment 1, and will not be repeated here.

[0078] Such as figure 2 As shown, in the embodiment of the present invention, the wilting device 1 includes a wilting tank body 11, a blower mechanism 12 and a heating mechanism. The tank body 11 is connected, and the heating mechanism is arranged on the blast duct. Specifically, the wilting tank body 11 has a length of 12m, a width of 1.2m, and a depth of 30cm. ...

Embodiment approach 3

[0090] The present invention also provides a black tea, which is prepared by the black tea processing method described in Embodiment 1 above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com