Injection molding machine for terminal forming

A technology for injection molding machines and terminals, which is applied in the field of injection molding machines for terminal molding, can solve problems such as high labor intensity, and achieve the effect of low labor intensity and increased replacement speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

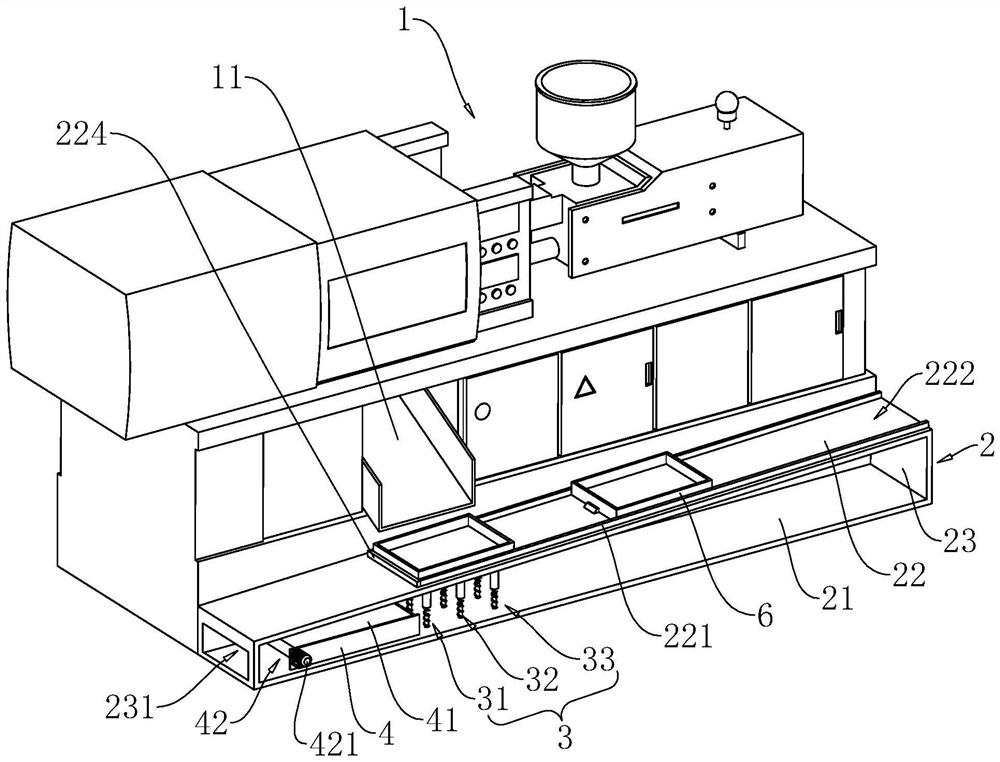

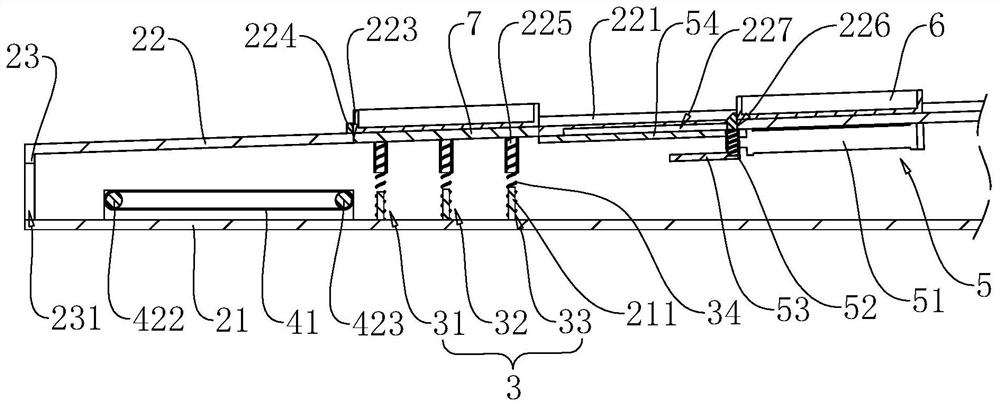

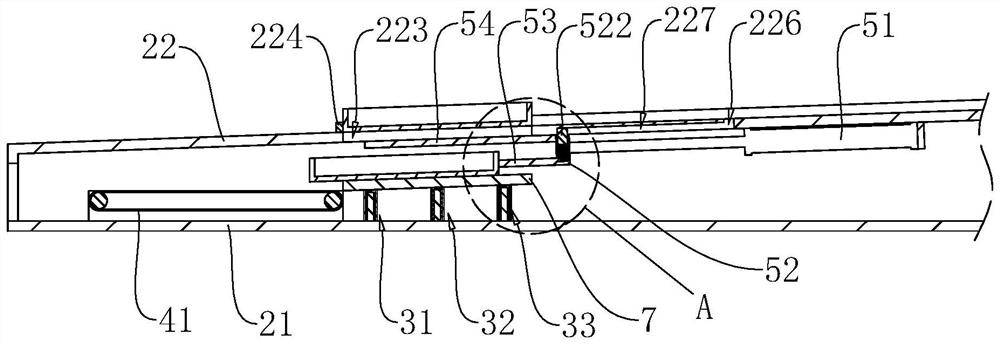

[0038] The following is attached Figure 1-4 The application is described in further detail.

[0039] The embodiment of the present application discloses an injection molding machine for terminal molding. refer to figure 1, The injection molding machine for terminal molding includes an injection molding machine body 1 , the injection molding machine body 1 is provided with a discharge port 11 , and the molded shell can be discharged from the discharge port 11 . Since the structure of the injection molding machine body 1 is a prior art, it will not be described in detail in this embodiment.

[0040] refer to figure 1 , figure 2 , the injection molding machine body 1 is fixedly connected with a receiving rack 2, and the receiving rack 2 includes a bottom plate 21 arranged horizontally, a positioning plate 22 arranged obliquely, and two vertical plates 23 fixed between the bottom plate 21 and the positioning plate 22, wherein The positioning plate 22 is located directly abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com