Large-diameter pipe joint hoisting fixture

A large-caliber, fixture technology, applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of not obvious comprehensive benefits, low efficiency of hoisting and unloading, unstable storage of steel pipes, etc., to achieve improved loading and unloading efficiency, simple structure, The effect of reliable lifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below with reference to the embodiments of the accompanying drawings.

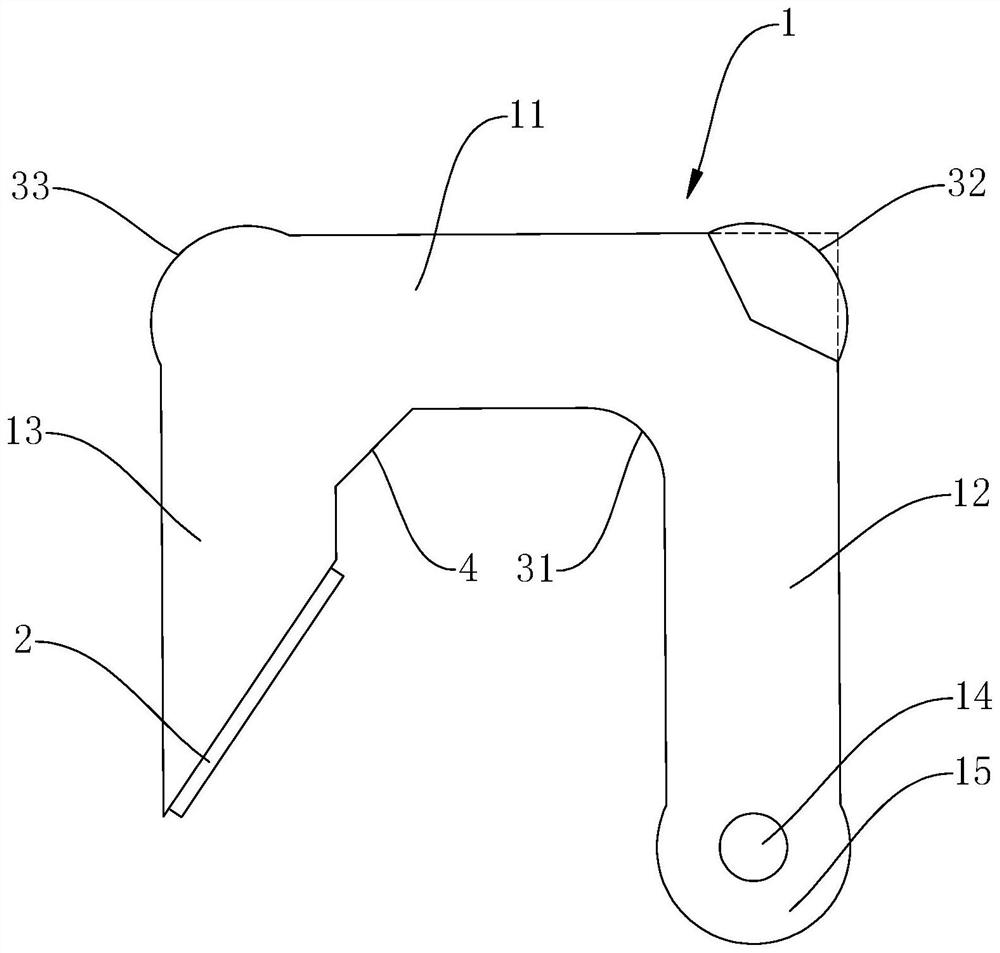

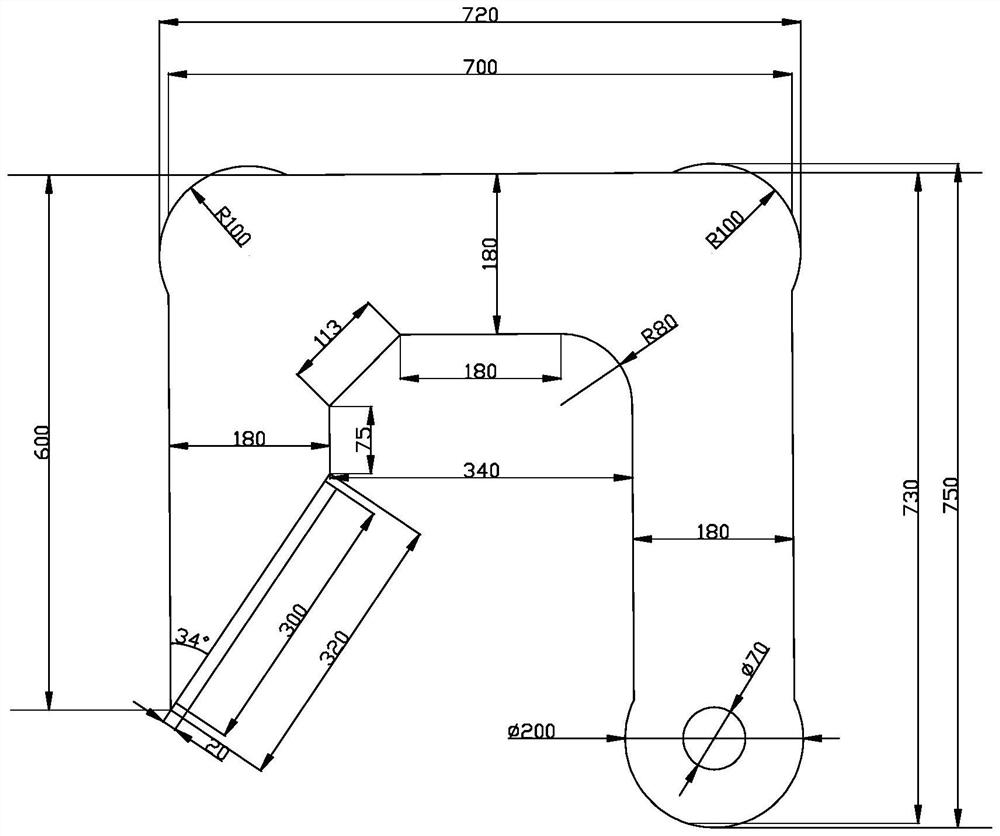

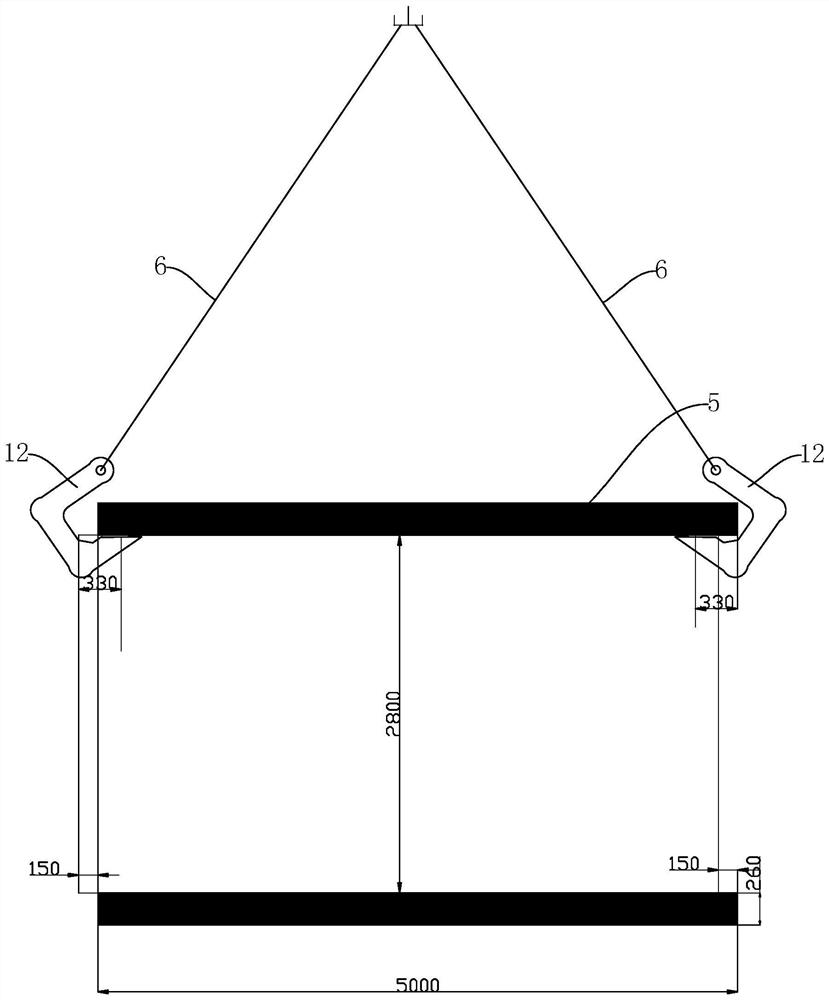

[0018] The large-diameter pipe section hoisting fixture of the embodiment, such as figure 1 and figure 2 As shown, it includes a fixture body 1 of equal thickness made of steel plate, the fixture body 1 is U-shaped as a whole, and the fixture body 1 includes a bottom plate 11, a hanging plate 12 and a supporting plate 13 that are integrally arranged. The hanging plate 12 and the supporting plate The plates 13 are respectively arranged vertically on both ends of the bottom plate 11, the hanging plate 12 is provided with a hanging hole 14, the top of the support plate 13 is inclined and arranged, the top of the support plate 13 is welded with a reinforcing plate 2, and the reinforcing plate 2 is from top to bottom. The width of the reinforcing plate 2 is larger than the thickness of the supporting plate 13 diagonally to the inner side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com