Pile head breaking device and pile breaking construction method

A construction method and pile head breaking technology, which is applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of uneven pile surface, high manpower consumption, low efficiency, etc., achieve smooth breaking section, reduce workload, The effect of improving the removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the purpose, technical solutions and beneficial effects of the present invention clearer, the preferred embodiments of the present invention will be described in detail below, so as to facilitate the understanding of the skilled person.

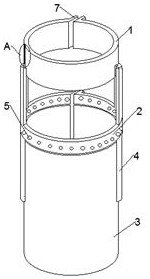

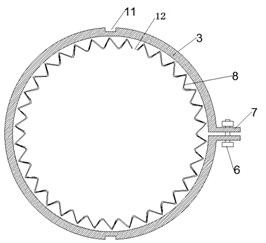

[0032] The pile head breaking device includes an upper clamping ring 1, a breaking positioning ring 2, a lower clamping ring 3 and clamping plates.

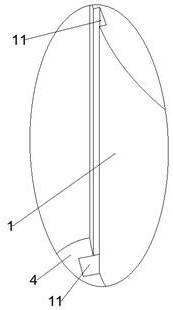

[0033] The upper clamping ring 1, the breaking positioning ring 2, and the lower clamping ring 3 are arranged from top to bottom, and the three are connected by two symmetrical connecting plates 4. The connecting plate 4 is a straight plate, and the connecting plate 4 and the upper clamping ring 1, The lower clamping ring 3 is respectively provided with relative bayonet sockets 11, and the relative bayonet sockets 11 form a card slot, and the card slots formed between the upper clamping ring 1 and the lower clamping ring 3 and the connecting plate 4 penetrate up and down, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com