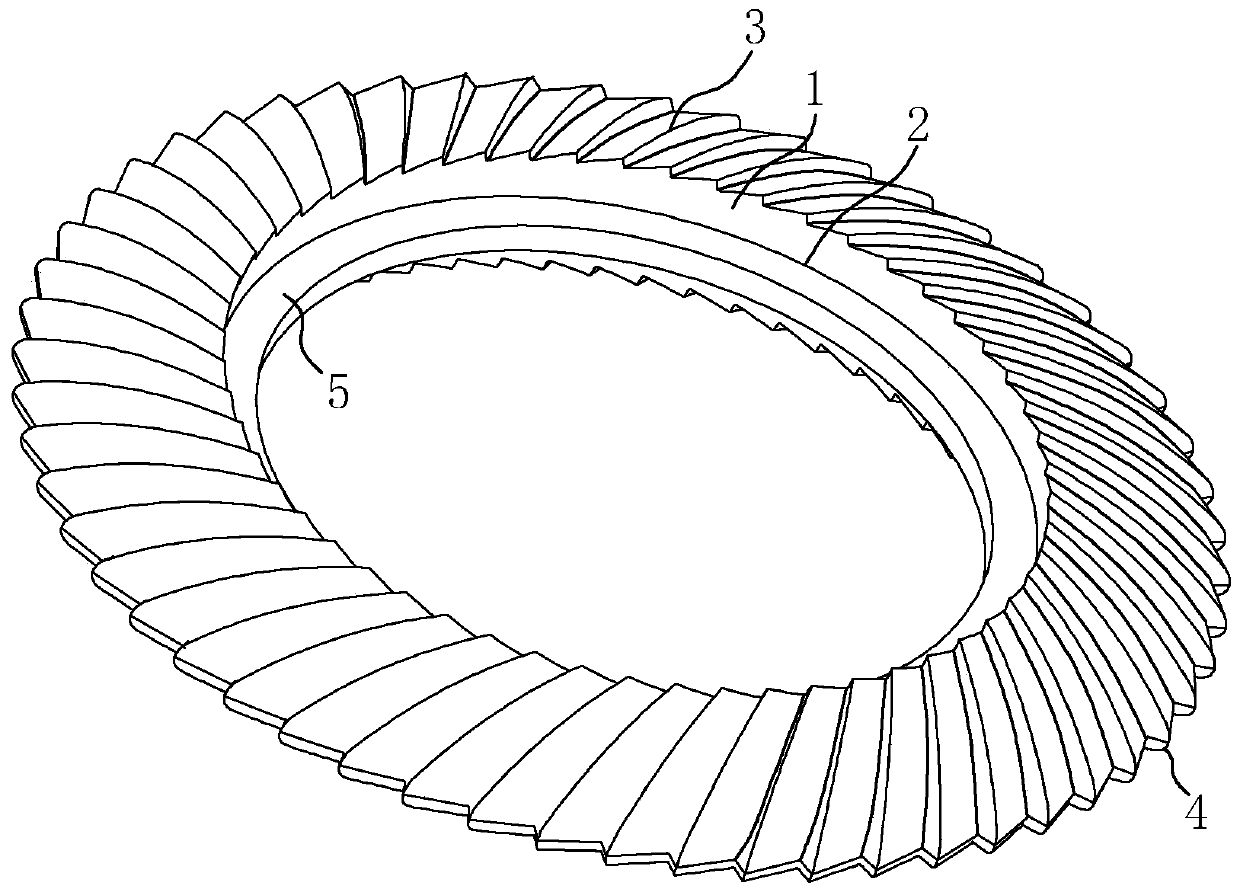

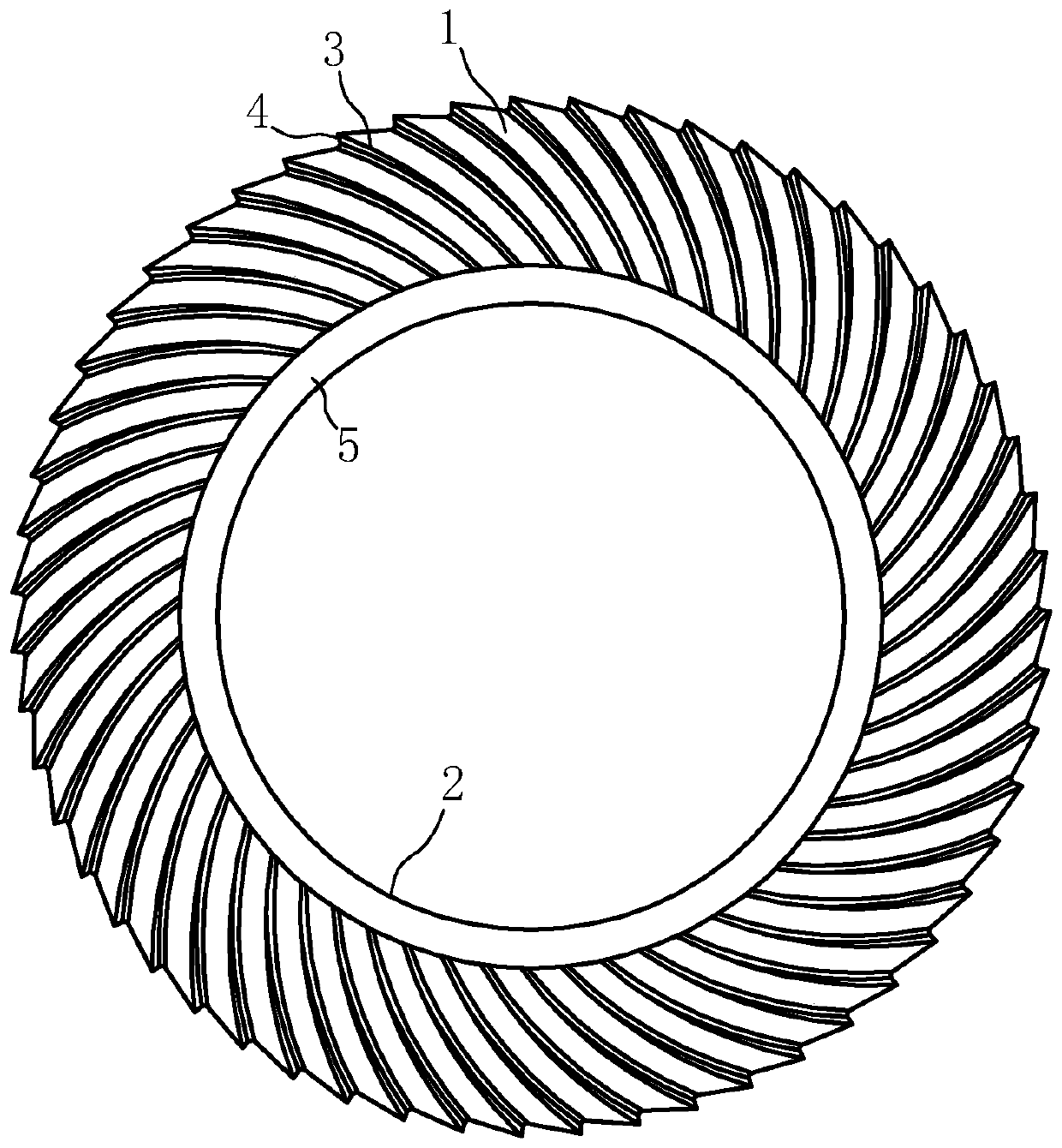

Whirlwind milling cutter and production process thereof

A whirlwind milling and body technology, applied in milling cutters, milling machine equipment, manufacturing tools, etc., can solve problems such as affecting the health of workers, affecting the quality of welding, and increasing temperature, so as to increase the usable area of body cutting and reduce welding. Influence of quality, effect of reducing dust generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

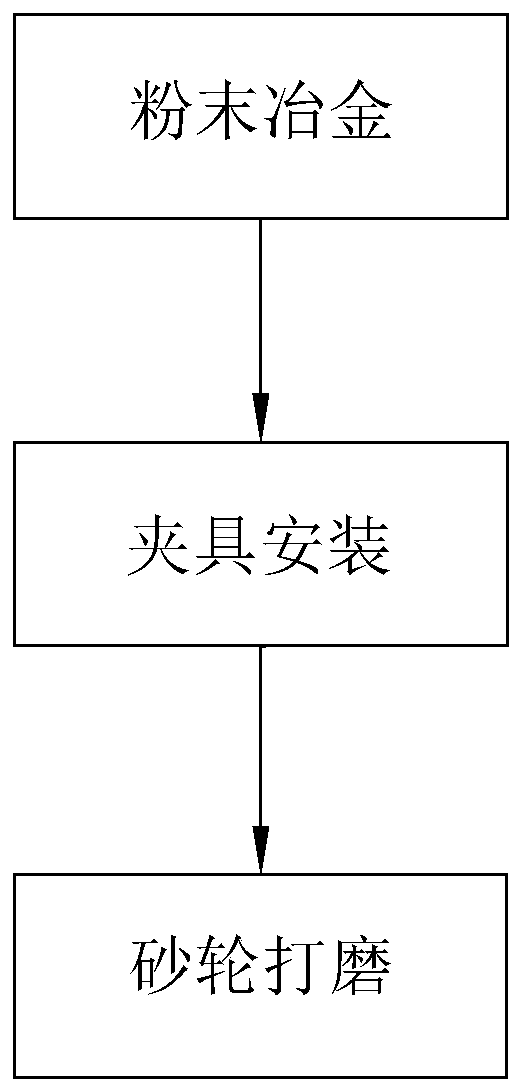

[0051] Embodiment 2: a kind of production technology of cyclone milling sharpener, as image 3 As shown, firstly, an annular body blank is obtained by traditional powder metallurgy, and the thickness of the body blank also gradually decreases from the center to the outside, and the inner wall of the mounting hole 2 in the middle of the body blank is provided with a convex ring 5; The material is fixed on the fixture, the fixture is as Figure 4 As shown, it includes a fixed plate 6 and a pressure plate 7. The fixed plate 6 and the pressure plate 7 are adapted to the mounting hole 2. The outer diameters of the fixed plate 6 and the pressure plate 7 are larger than the inner diameter of the convex ring 5. A cylinder 8 is coaxially fixed, and the cylinder 8 is used to be clamped and fixed by the three-jaw chuck on the grinding machine; a stud 9 is protruded on the fixed plate 6, and a stud 9 is provided on the pressure plate 7. The threaded hole 10 of threaded connection, the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com