A kind of anti-shake camera drive device

A driving device and anti-shake technology, which is applied in the direction of developing and printing devices, focusing devices, projection devices, etc., can solve the problems of complicated assembly, easy-to-break solder joints occupying space, and unclear photos, so as to enhance the compensation effect and solve solder joint occupation If the space is too high, the effect of improving the anti-shake performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

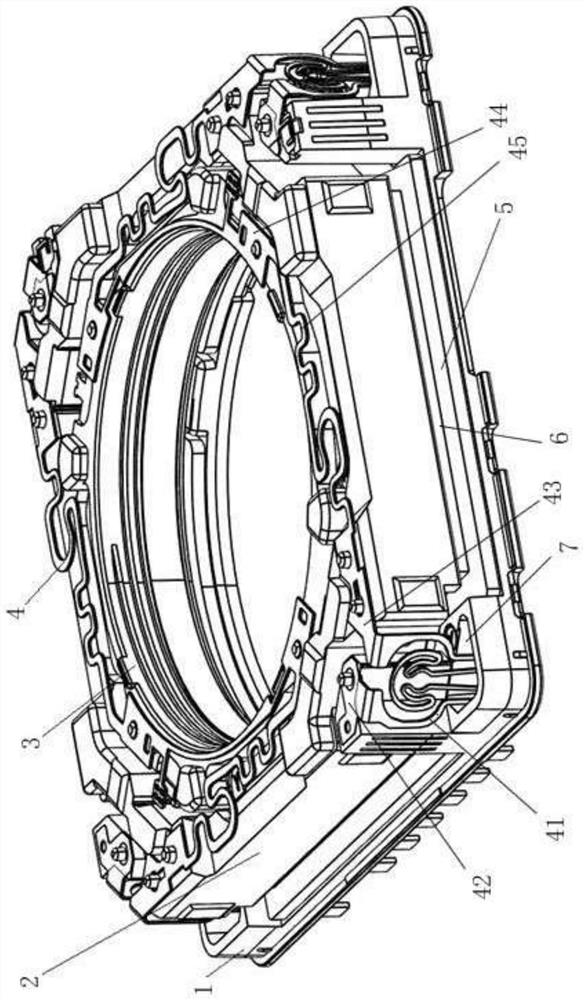

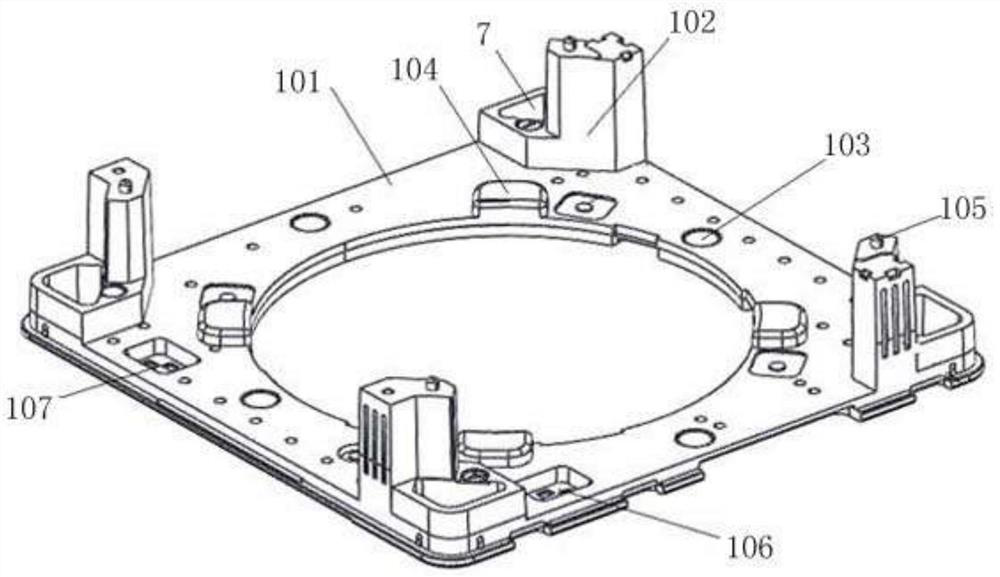

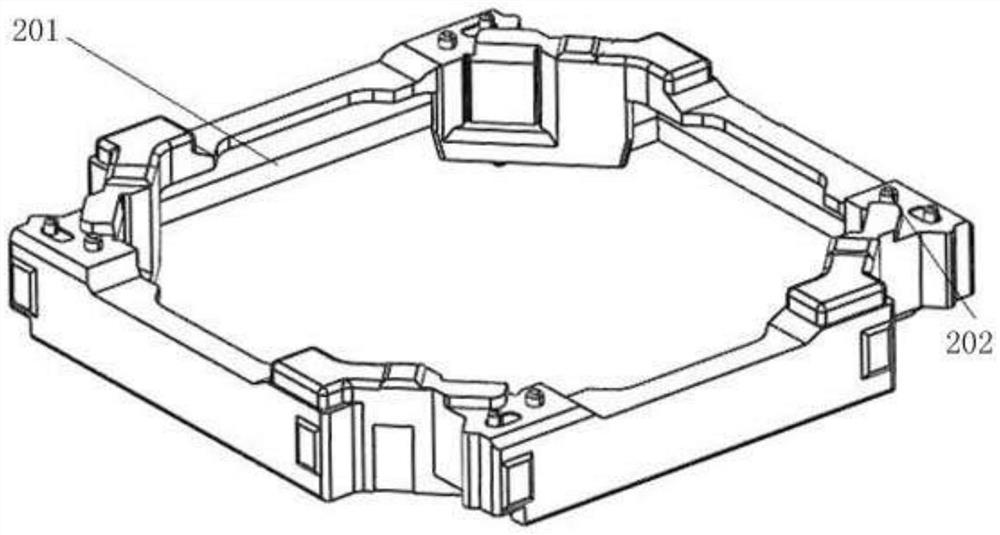

[0037] like Figure 1-Figure 15 As shown, the anti-shake camera driving device includes a base 1, a protective shell 13, an OIS assembly disposed in the protective cavity formed by the base 1 and the protective shell 13, an AF assembly disposed inside the OIS carrier 2 of the OIS assembly, The elastic sheet assembly between the OIS carrier 2 of the OIS assembly and the AF carrier 3 of the AF assembly and the base 1 is a closed-loop control assembly for detecting the movement of the OIS carrier 2 and the AF carrier 3 relative to the base 1 . The elastic piece assembly includes an upper elastic piece 4 and a lower elastic piece 9 .

[0038] Wherein, the four corners of the upper surface of the bottom plate 101 of the base 1 are respectively provided with damping grooves 7 for storing damping glue. The number of damping grooves 7 is the same. The upper elastic sheet 4 has a fixed part I 44 connected with the top surface of the AF carrier 3, a fixed part II 43 connected with the t...

Embodiment 2

[0048] The anti-shake camera drive device, such as Figure 16 As shown, the OIS coil 5 of the OIS assembly adopts a split racetrack coil, and the number of the split racetrack coils is four, which corresponds to the four magnets 601 of the magnet assembly 6 one-to-one. A plurality of positioning bosses 109 corresponding to the split racetrack coils are provided on four sides of the upper surface of the base plate 101 , and the split racetrack coils are fixed to the base plate 101 through the positioning bosses 109 .

[0049] Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com