High-salt-mist corrosion-resistant light woven wave-proof sleeve and preparation process thereof

A preparation process and corrosion-resistant technology, applied in wire processing, other household appliances, cable/conductor manufacturing, etc., can solve the problems of inability to increase the weaving speed, inability to increase the spindle, etc., to improve the weaving capacity, control the weaving tension, and speed up the weaving. effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to further understand the features, technical means, and specific objectives and functions achieved by the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

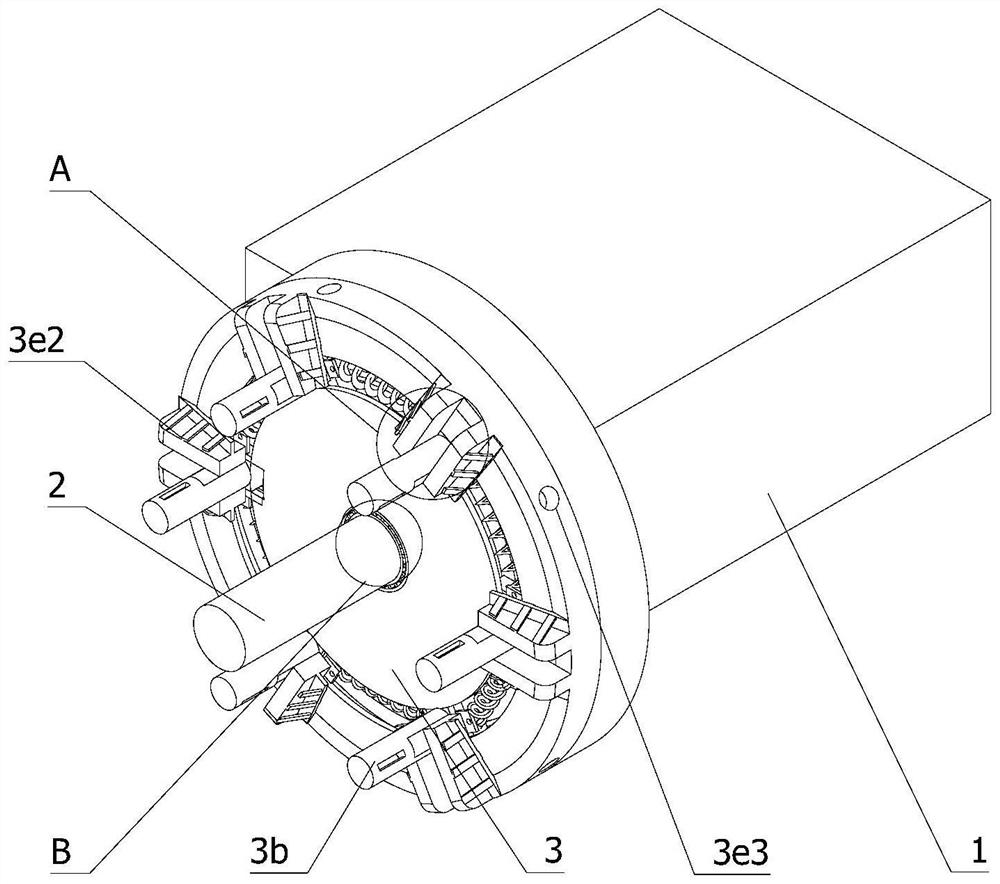

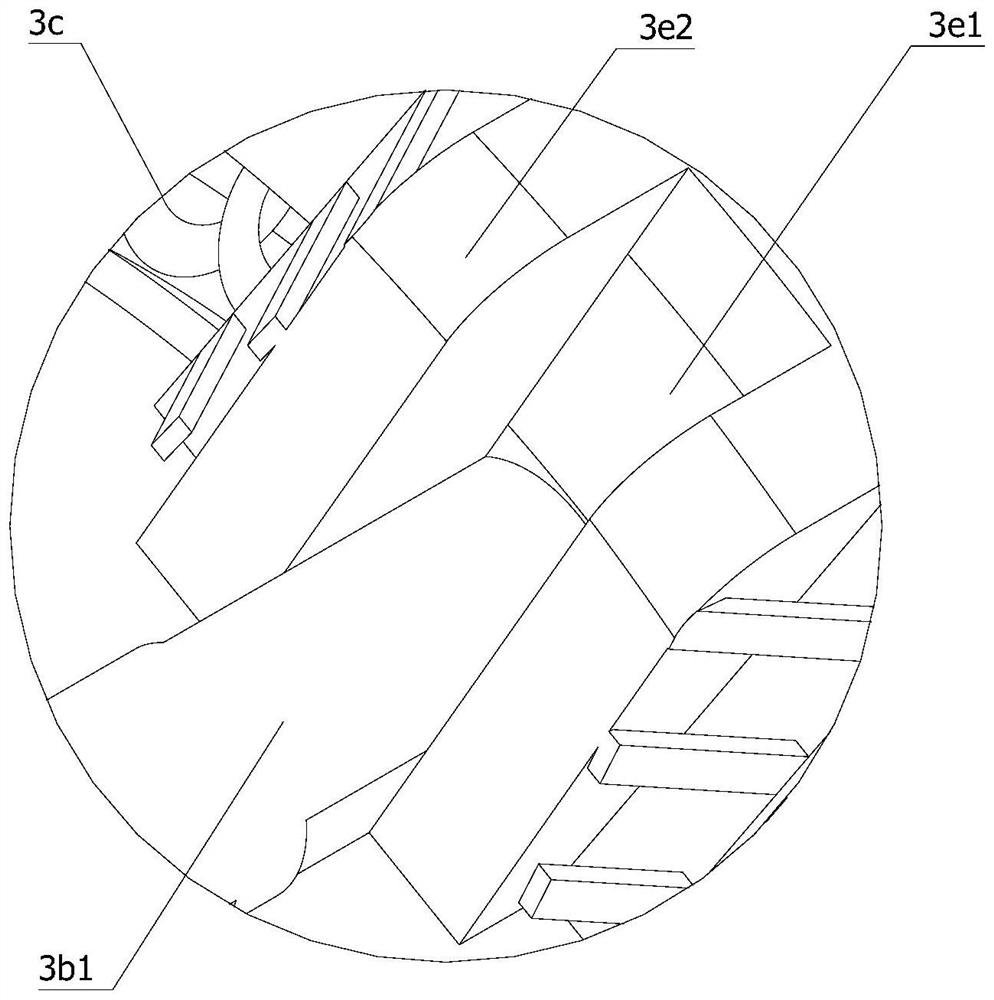

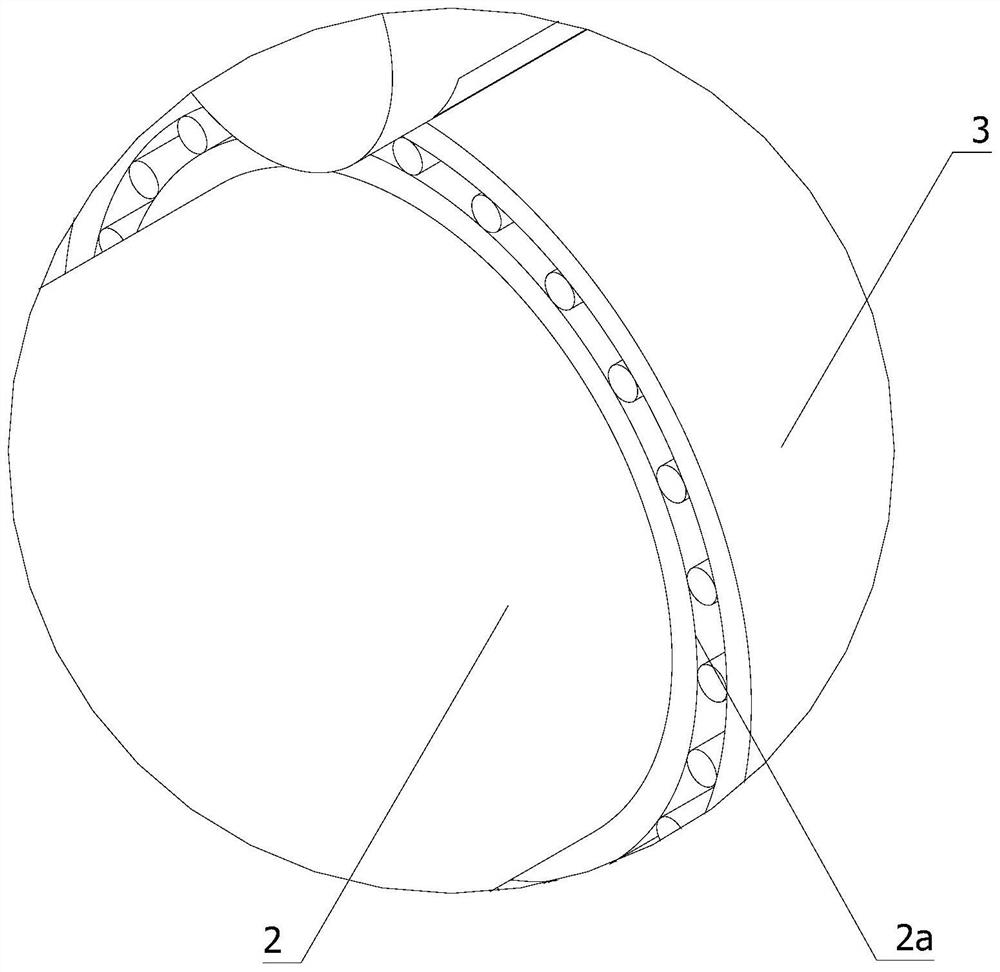

[0048] Such as Figure 1 to Figure 10 As shown, this application provides:

[0049] A high-salt-spray corrosion-resistant light-weight braided anti-wave cover. The anti-wave cover is formed by braiding multiple copper wires by winding equipment. The winding equipment includes a frame 1, a wire winding column 2, a turntable 3 and a power module 4. The column 2 is set on the frame 1 rotatably around its own axis, the turntable 3 is set on the frame 1 rotatably around its own axis, the turntable 3 is coaxially sleeved on the outside of the winding column 2, and the power module 4 is used to drive The winding column 2 and the turntable 3 rotate in opposite directions; the turntable 3 is provided with a fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com