Push-pull type guide blank moving device of vertical casting machine

A technology of push-pull and conduction device, which is applied in the field of push-pull guide blank moving device, which can solve the problem that the inner end cannot realize synchronous fit-type pressing and pushing, it is inconvenient for continuous speed reduction to cooperate with blanking operation, and it is inconvenient for the setting of auxiliary transposition And other problems, to achieve the effect of mechanical cooperation in production, change of work again, and hindrance function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

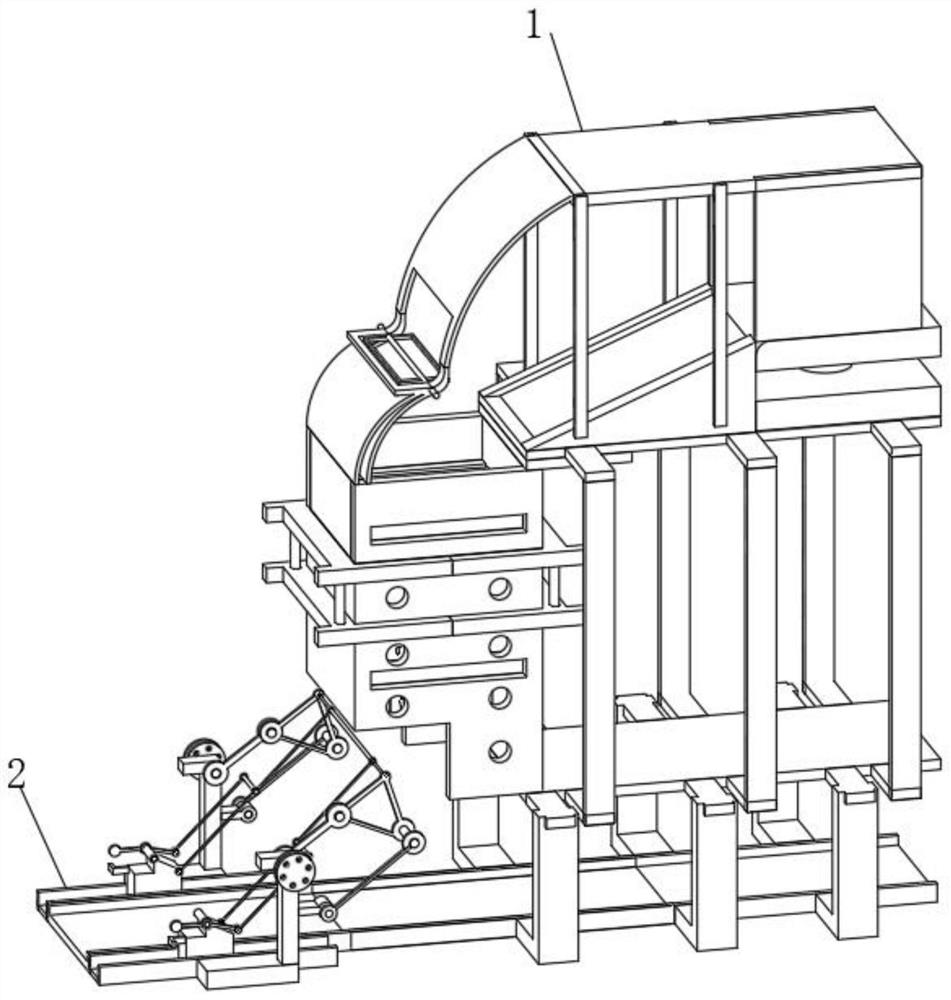

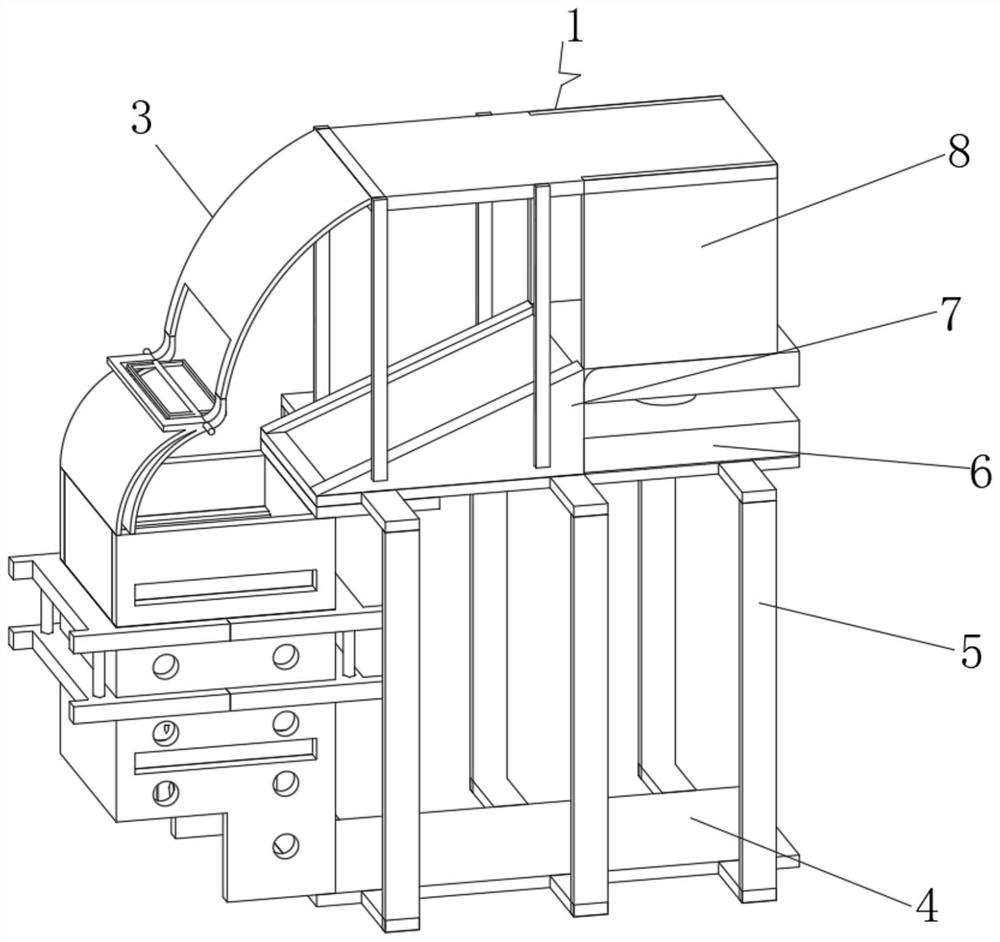

[0027] see Figure 1-6 , the present invention provides a technical solution: a push-pull guide blank moving device for a vertical casting machine includes a conduction device 1, and a transposition connection device 2 is fixedly connected to the bottom end of the conduction device 1, and is set through the connection of the inner end conduction device 1. , which can help the transmission task of the workpiece and realize the connection and conduction of the workpiece. Through the setting of the transposition connection device 2, the position conversion task can be realized, and the adjustment and control of the inner end can be facilitated;

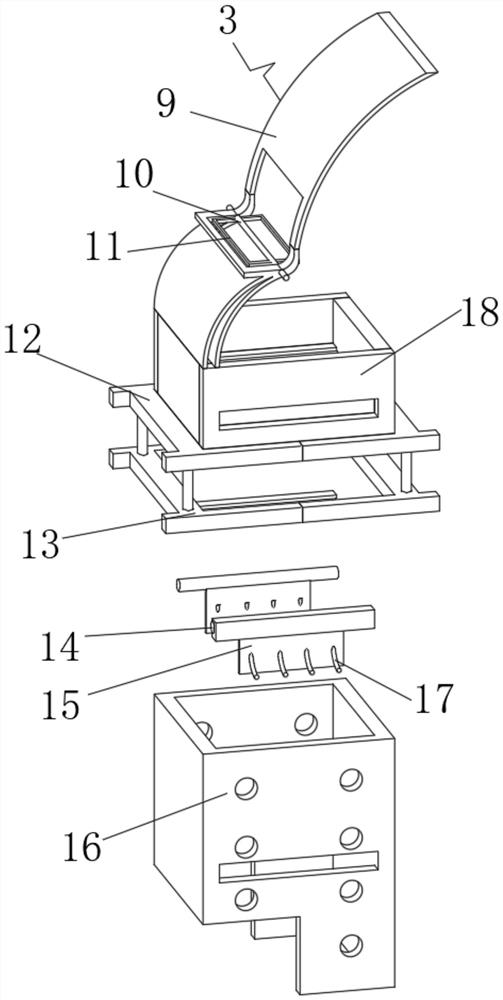

[0028] The transmission device 1 includes a deceleration component 3, a support plate frame 4, a pole stand 5, a connecting guide rod 6, a ramp frame 7 and a side template 8. The support plate frame 4 is arranged at the bottom position of the inner end of the transmission device 1, and the support plate frame The upper end of 4 is fixedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com