Electric motorcycle running uniform speed control system capable of automatically adjusting torque

An electric motorcycle, automatic adjustment technology, applied in the direction of vehicle gearbox, vehicle parts, wheel transmission device, etc. The effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

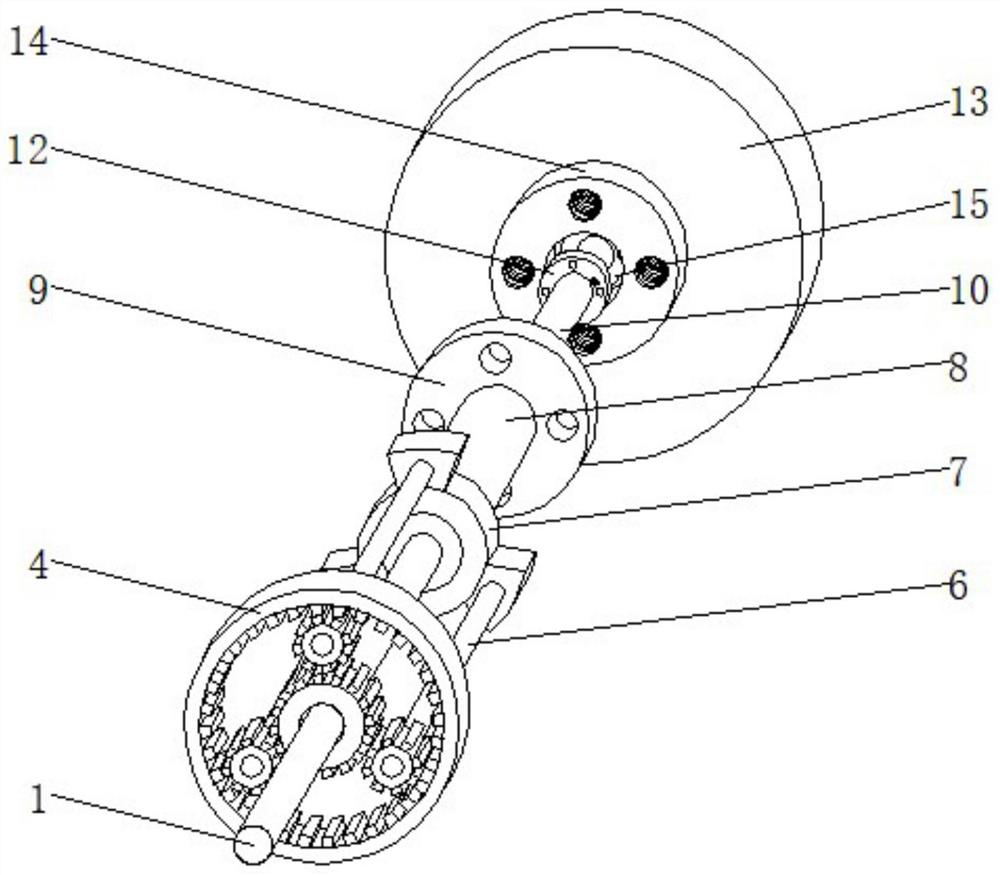

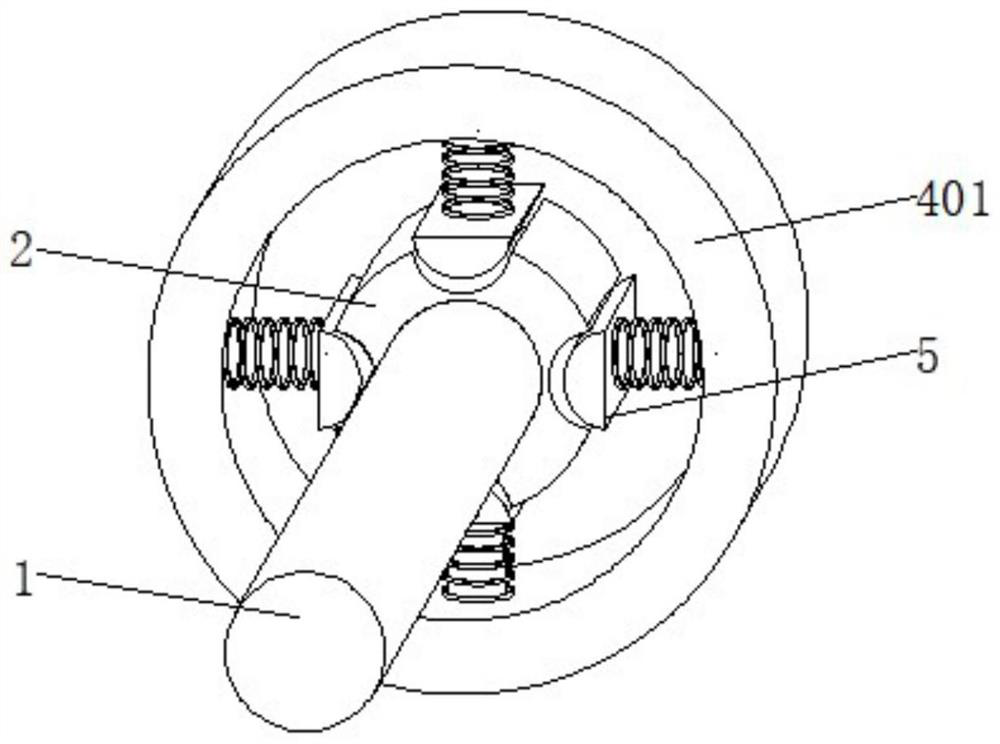

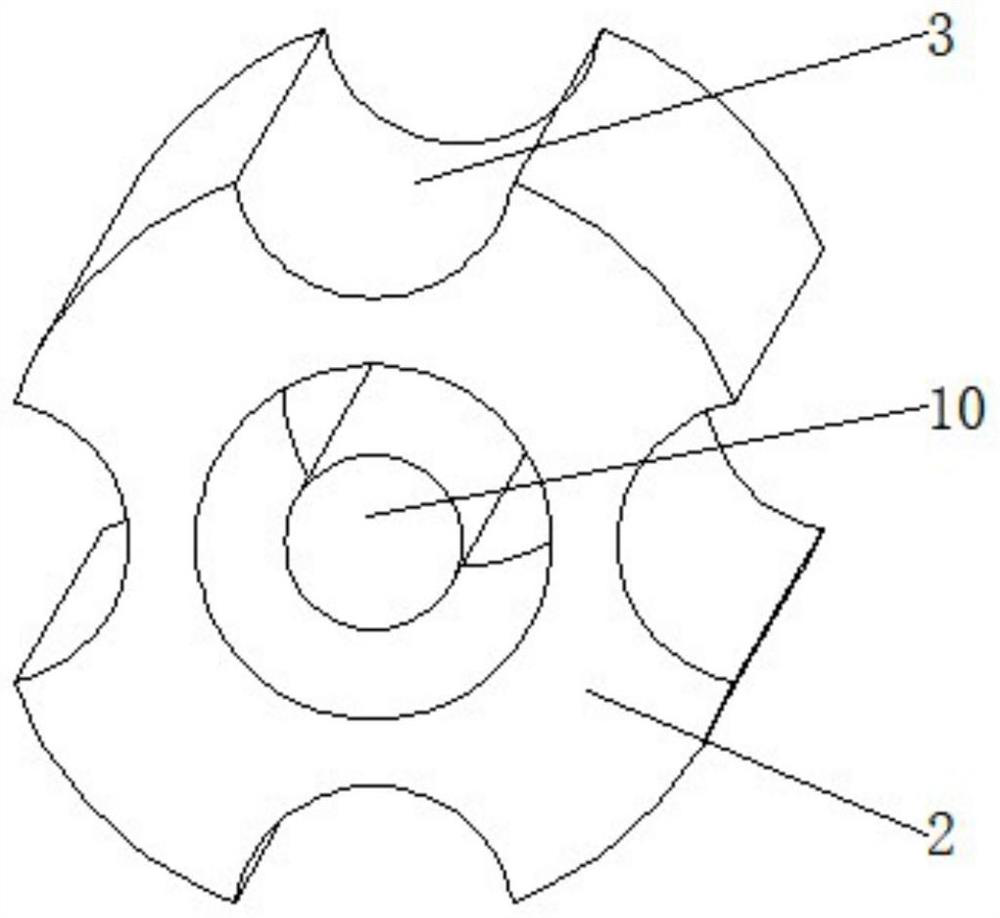

[0029] see Figure 1-7 , an electric motorcycle running average speed control system capable of automatically adjusting torque, comprising a driving rod 1, a first connecting ring 2 is arranged on one side of the driving rod 1, and a card slot 3 is opened on the outer wall of the first connecting ring 2, the first The outer wall of the connecting ring 2 is provided with a planetary gear structure 4. The planetary gear structure 4 includes a driving gear 401, a driven gear 402 and a gear ring 403. The inner wall of the driving gear 401 is provided with a first limit structure 5, and the driven gear 402 is far away from the driving rod. 1 is provided with a connecting rod 6, the side of the connecting rod 6 away from the driven gear 402 is provided with a second connecting ring 7, and the side of the second connecting ring 7 away from the connecting rod 6 is provided with a first driven rod 8, The side of the first driven rod 8 away from the second connecting ring 7 is provided ...

Embodiment 2

[0033] see figure 1 , on the basis of Embodiment 1, a second driven rod 10 is provided inside the first connecting ring 2, and a second connecting flange 12 is provided on the side of the second driven rod 10 away from the driving rod 1, and the second driven The outer diameter of the rod 10 matches the inner diameter of the first driven rod 8, the second driven rod 10 runs through the first driven rod 8, and the second driven rod 10 is connected with the second connecting ring 7 and the first driven rod. The rod 8 is connected in rotation, and the second driven rod 10 plays the role of power transmission for the tire 13 when the electric motorcycle rotates at high speed; the side of the second connecting flange 12 away from the second driven rod 10 is provided with a tire 13 The inside of the tire 13 is provided with a first connection hole 14 and a second connection hole 15, the tire 13 is fixedly connected to the first connection flange 9 through the first connection hole 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com