Piezoelectric pulse propeller with high mass flow and underwater robot

An electric pulse and thruster technology, applied in ship propulsion, propulsion components, ship construction, etc., can solve the problems of insufficient mass flow, unidirectional fluid motion, and high heat loss, and reduce the frequency of atomic dislocation motion. Effect of surface area and volume, heat loss reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

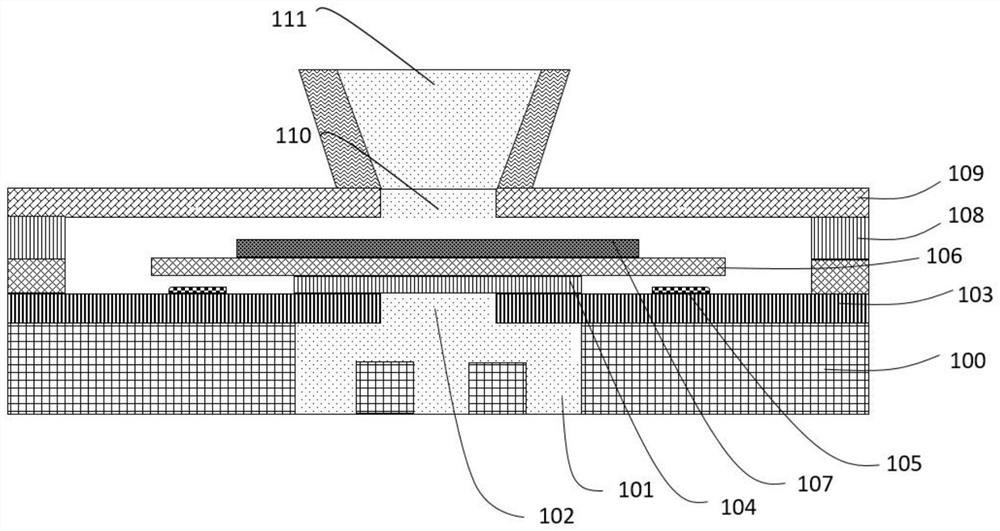

[0036] Such as figure 1 As shown, a high-quality flow piezoelectric pulse impeller includes an inflow layer 100, a composite alloy layer 103, a vibration substrate layer 106, a vibration layer 107, an upper electrode layer 108 and a shell layer 109 stacked in sequence, and The plugging layer 104 and the O-ring 105 are located between the composite alloy layer 103 and the vibrating substrate layer 106 .

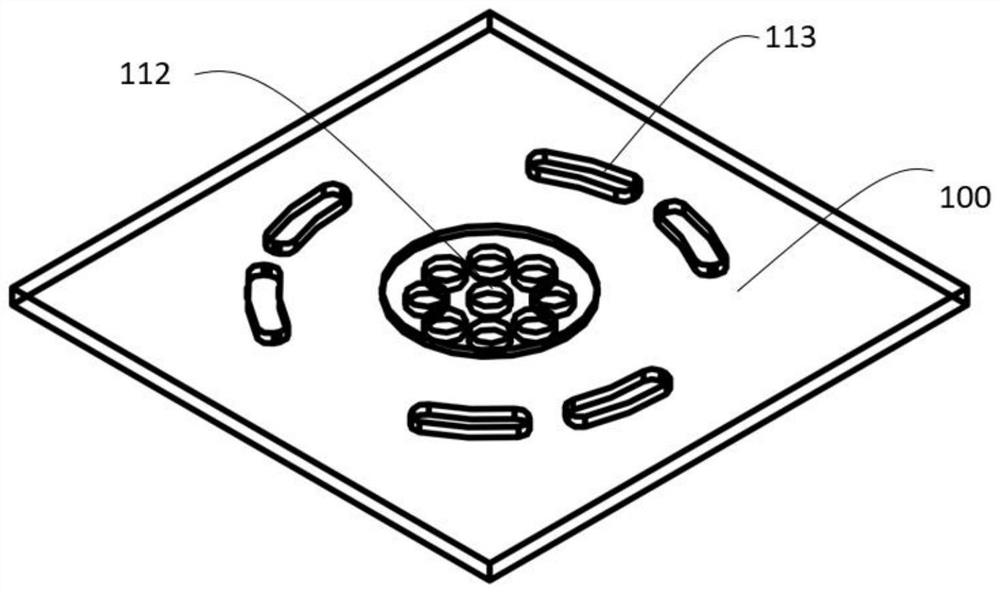

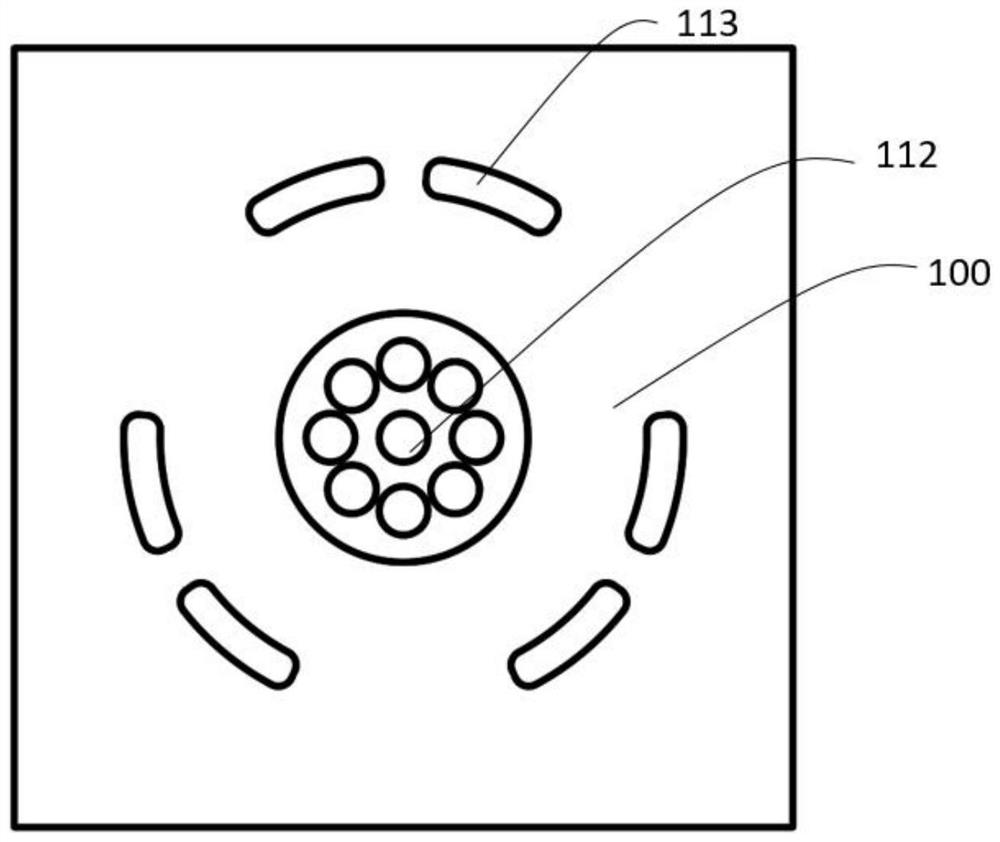

[0037] Such as figure 2 and 3As shown, a first flow channel 101 is opened on the inflow layer 100 ; a second flow channel 102 is opened on the composite alloy layer 103 . The first flow path 101 and the second flow path 102 are butted together to form an input flow path. The first flow channel 101 includes a flow cavity and nine liquid inlets. Each liquid inlet is in communication with the flow cavity; the flow cavity is in communication with the second flow path 102 .

[0038] The vibrating substrate layer 106 includes an edge fixing part, a connecting piece 116 and a c...

Embodiment 2

[0066] An underwater robot is equipped with one or more piezoelectric pulse thrusters as described in Embodiment 1 at the tail; by controlling the input voltage and frequency of the piezoelectric pulse thrusters, the propulsion force of the piezoelectric pulse thrusters can be adjusted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com