Liquid accumulator and compressor assembly

A technology of liquid receiver and liquid separator, which is applied in the field of compressors, can solve the problems of poor liquid separation ability of liquid separator and increase of liquid carried by exhaust of liquid separator, so as to reduce the amount of liquid carried by exhaust and reduce Fluid volume, the effect of avoiding liquid shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

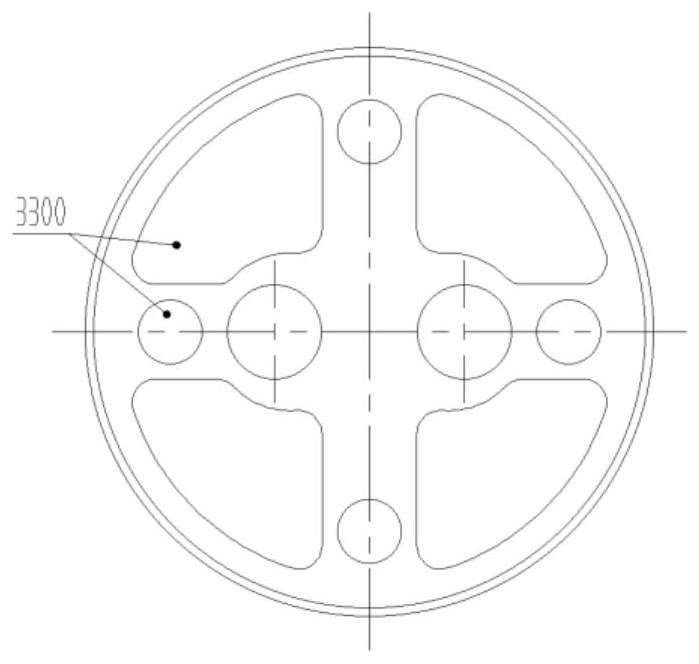

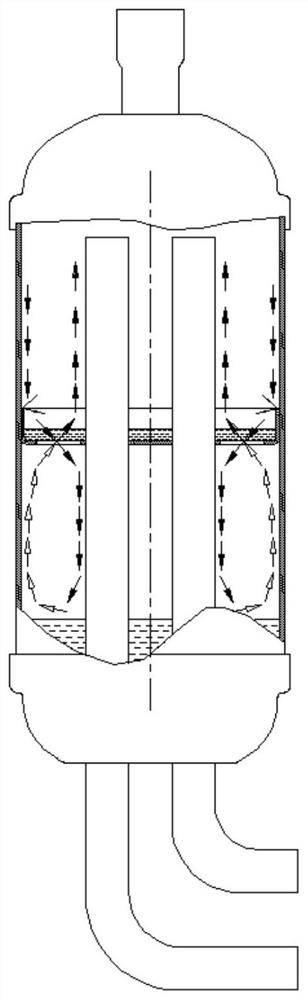

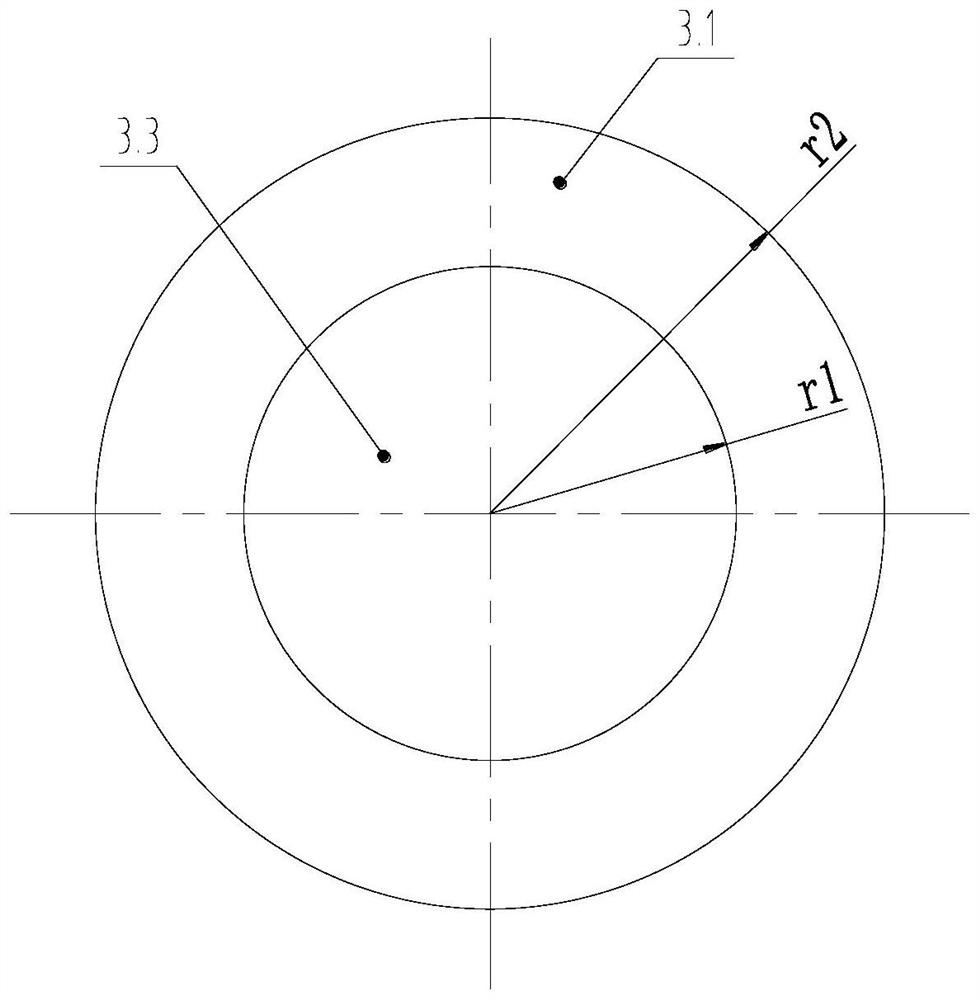

[0053] Example 1, such as Figure 3a-5 As shown, in some embodiments, the first partition 3.1 is located above the second partition 3.2, at this time, an air flow channel is formed between the first partition 3.1 and the second partition 3.2, At the same time, the flow channel 3.5 is formed as a liquid flow channel, so that the liquid can flow through the flow channel 3.5 to the bottom of the second partition 3.2, and the gas can pass through the first partition 3.1 and the second partition 3.2 to flow above the first partition 3.1. This is the preferred structural form of Embodiment 1 of the present invention, that is, the first partition is located above the second partition, and the gap between the first partition and the second partition is used for upward gas flow, and the second partition The opened circulation channels are used to circulate liquid downwards, thereby forming separate air flow channels and liquid flow channels, preventing gas-liquid hedging and improving...

Embodiment 2

[0057] Example 2, such as Figure 6a-Figure 9 As shown, in some embodiments, the first partition 3.1 is located above the second partition 3.2, at this time, the first part of the circumferential segment of the first partition 3.1 and the second partition 3.2 A first liquid flow channel is formed between the first part of the circumferential section of the first partition, and an airflow channel is formed between the second part of the circumferential section of the first partition 3.1 and the second part of the circumferential section of the second partition 3.2, At the same time, the flow channel 3.5 is formed as a second liquid flow channel, so that the liquid can flow to the second separator 3.3 through the first liquid flow channel, and flow to the second separator 3.2 through the flow channel 3.5 Below, the gas can flow to the first partition 3.1 through the gas flow channel between the second partial circumferential section of the first partition 3.1 and the second part...

Embodiment 3

[0064] Example 3, such as Figures 10a-13b , in some embodiments, the first partition 3.1 is located below the second partition 3.2, at this time a liquid flow channel is formed between the first partition 3.1 and the second partition 3.2, and at the same time The circulation channel 3.5 is formed as an air flow channel, so that the liquid can flow to the bottom of the second separator 3.2 through the gap between the first separator 3.1 and the second separator 3.2, and the gas can pass through the second separator 3.2. The flow channel 3.5 flows to the top of the first partition 3.1. This is the preferred structural form of Embodiment 3 of the present invention, that is, the first dividing plate is located below the second dividing plate, and the gap between the first dividing plate and the second dividing plate is used for direct downward flow of liquid, and the second dividing plate The circulation channel opened on the partition is used to circulate gas upwards, thereby f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com