High efficiency heat exchanger for freon low temperature unit

A technology of heat exchangers and freon, applied in refrigerators, refrigeration components, evaporators/condensers, etc., can solve problems such as uneven distribution of refrigerant, loss of evaporation and heat exchange, and impact on the overall efficiency of heat exchange tube bundles. Achieve the effects of improving operating efficiency and compressor reliability, increasing evaporation and boiling heat transfer coefficient, and avoiding wet compression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

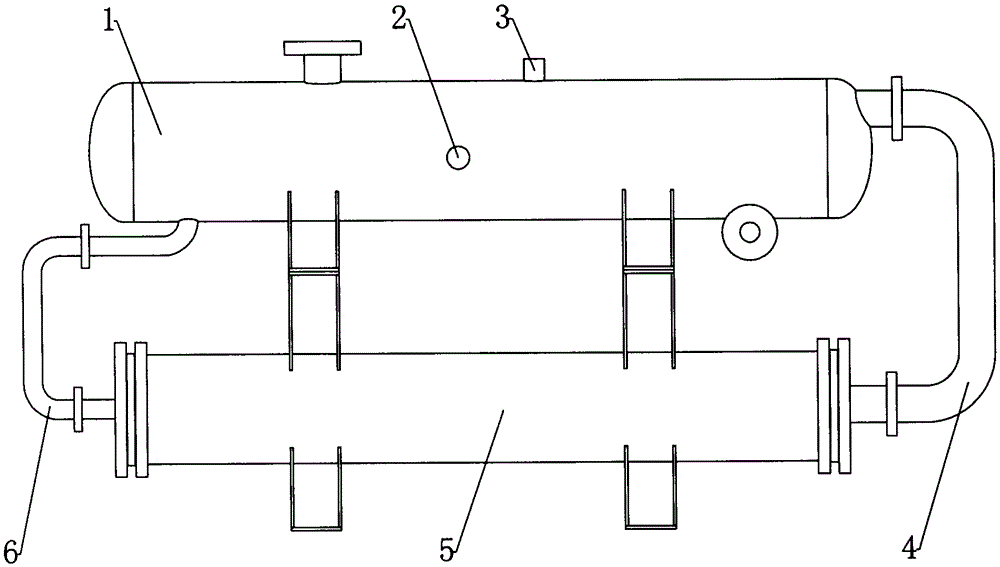

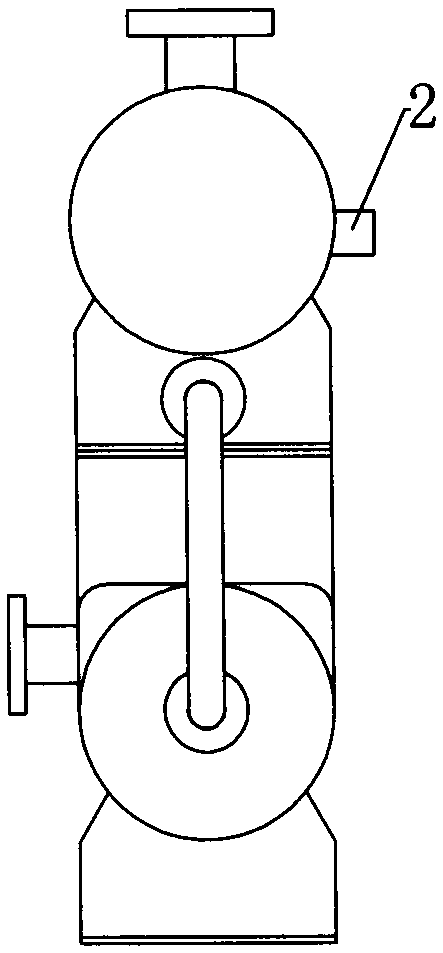

[0016] Examples, see figure 1 and figure 2 Shown: a high-efficiency heat exchanger for a Freon low-temperature unit, which includes a compressor. The high-efficiency heat exchanger for Freon cryogenic units includes a gas-liquid separation device 1 , an evaporator 5 , a gas pipe 4 and a liquid pipe 6 . Specifically, the gas-liquid separation device 1 is located above the evaporator 5 . At the same time, on one side of the gas-liquid separation device 1, the upper end of the liquid pipe 6 communicates with the gas-liquid separation device 1, and the lower end communicates with the inlet of the evaporator 5; on the other side of the gas-liquid separation device 1, the The upper end of the gas pipe 4 communicates with the gas-liquid separation device 1 , and the lower end communicates with the outlet of the evaporator 5 . In this way, the refrigerant flowing in from the condenser enters the gas-liquid separation device 1, and a certain hydrostatic column pressure is maintaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com