Silicon wafer feeding and discharging system

A silicon wafer and blanking technology, applied in the fields of photovoltaic power generation, electrical components, climate sustainability, etc., can solve the problems of large space, high cost, complex structure, etc., to improve the degree of automatic control and prevent reverse discharge errors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

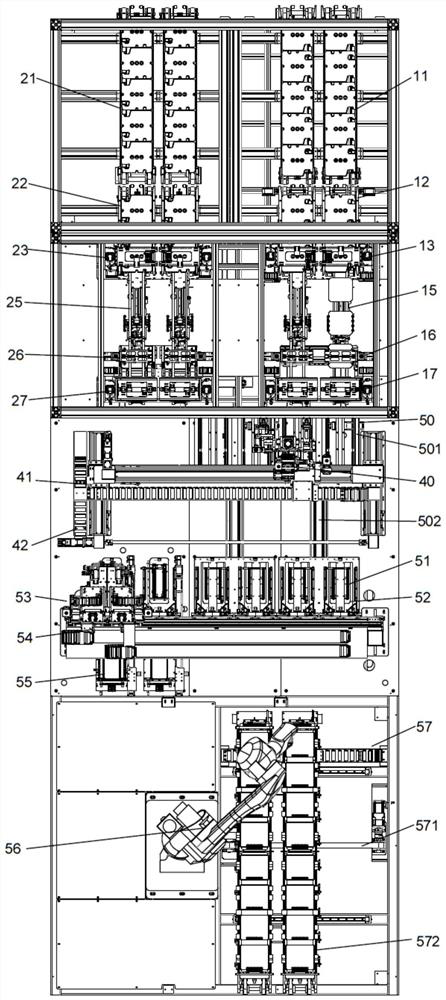

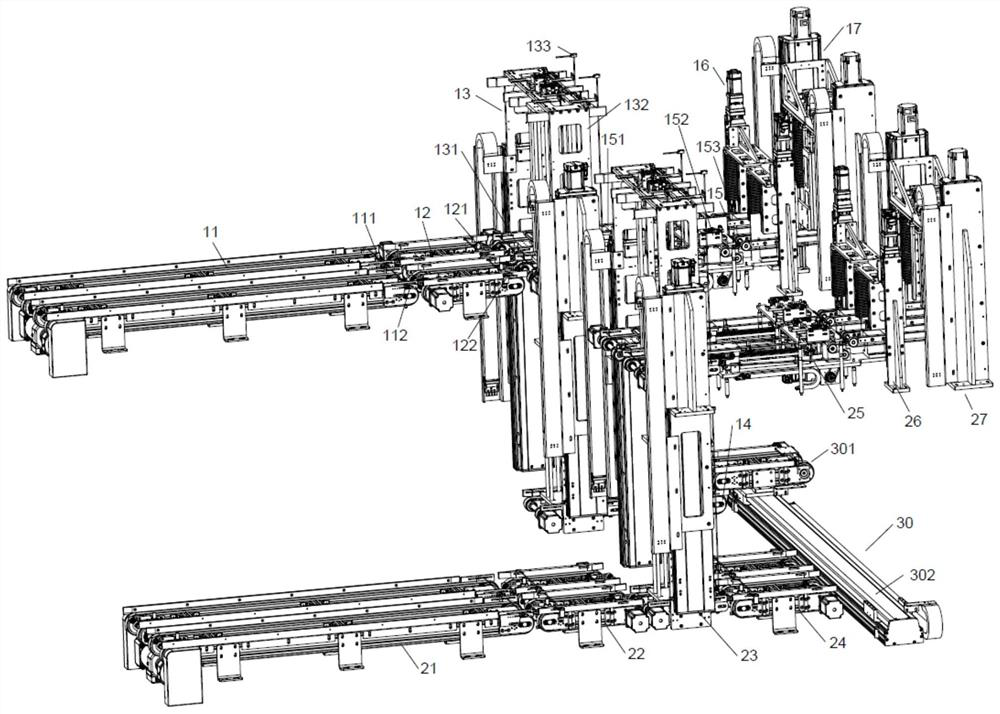

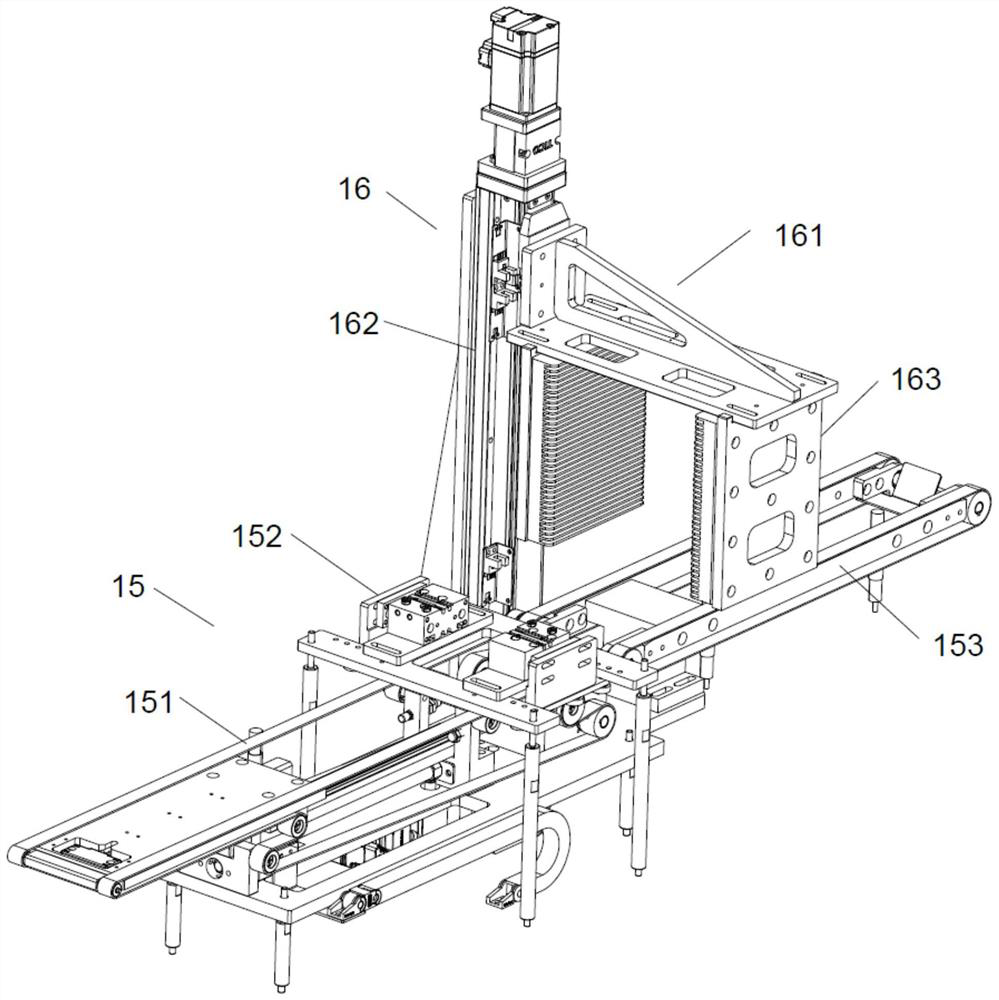

[0037] Such as Figure 1-11 As shown, a silicon wafer loading and unloading system includes a wafer guide device, a silicon wafer turning device and a handling device. The wafer guide device includes a loading guide assembly, an unloading guide assembly and a connecting loading guide assembly and the traversing conveying mechanism 30 of the unloading guide assembly, the loading guide assembly controls the silicon wafer feeding process, the unloading guide assembly controls the silicon wafer unloading process, and the traversing conveying mechanism 30 pairs the loading guide assembly and the lower The flower basket of the material guide assembly is circulated, and the silicon wafer turning device includes a silicon wafer turning mechanism 40, a silicon wafer traversing mechanism 41 and a silicon wafer offset mechanism 42, and the silicon wafer traversing mechanism 41 and the silicon wafer offset mechanism 42 controls the movement of the wafer turning mechanism 40, the silicon w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com