Cooling device suitable for semiconductor laser

A technology for cooling devices and lasers, which is applied in the direction of semiconductor lasers, lasers, laser components, etc., can solve the problems that the cooling device cannot give warnings to the staff, affect the service life of semiconductor lasers, and reduce the heat dissipation effect of electronic components. The overall cost is high, the sensor is easily damaged, and the effect of avoiding economic loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

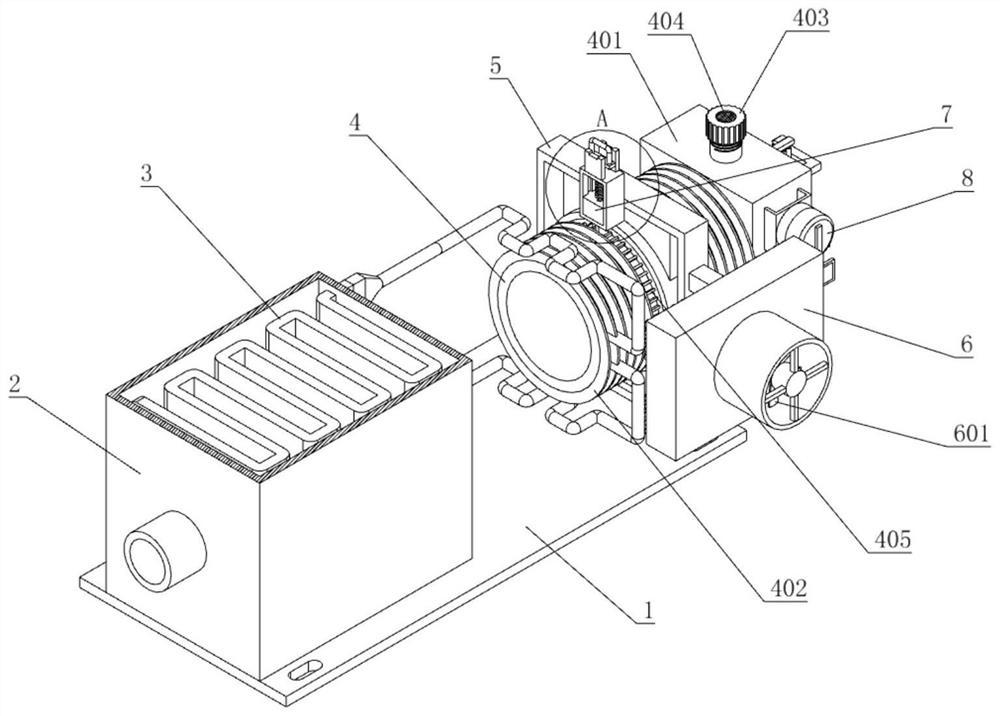

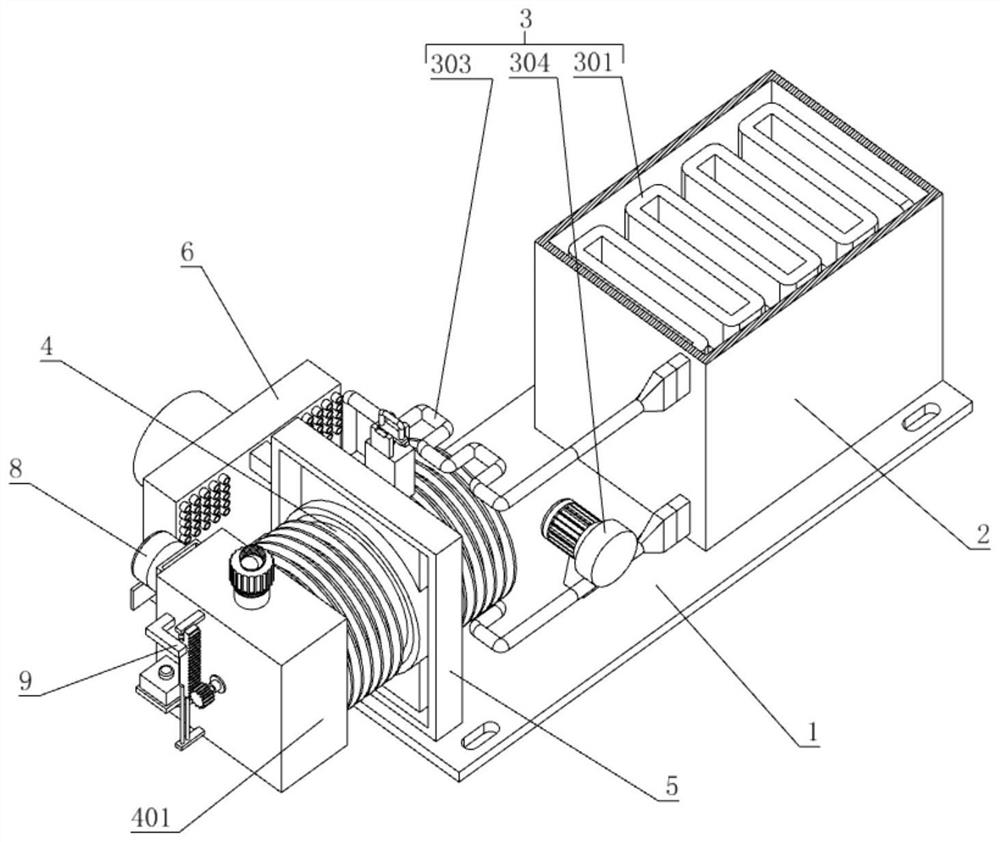

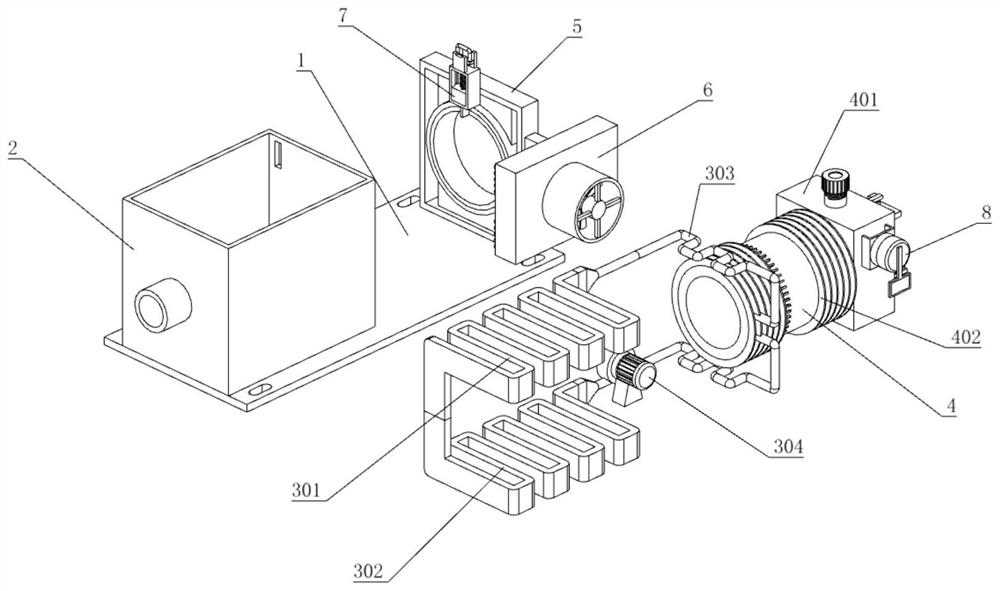

[0035] Example: Please refer to Figure 1 to Figure 9 :

[0036] The present invention proposes a cooling device suitable for semiconductor lasers, comprising: an installation base plate 1; a laser housing 2 is installed on the front side of the upper end of the installation base plate 1, and a support frame 5 is fixed on the rear side of the upper end surface of the installation base plate 1, for The heat part 3 is supported, and the heat absorbing part 3 is installed inside the laser shell 2 for absorbing the heat inside the laser shell 2. The heat absorbing part 3 includes an upper heat absorbing pipe 301, a lower heat absorbing pipe 302, and an infusion hose 303 and circulation pump 304, the upper heat-absorbing pipe 301 and the lower heat-absorbing pipe 302 are respectively installed on the upper and lower sides of the laser housing 2, and the distance between the upper heat-absorbing pipe 301 and the lower heat-absorbing pipe 302 accounts for 1 / 2 of the inner height of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com