Vibration device for membrane module

A vibrating device and membrane module technology, which is applied in the direction of vibrating fluid, membrane technology, and semi-permeable membrane separation, can solve problems such as limited scouring effect, unbalanced membrane flux, and single force direction of membrane filaments, so as to avoid scouring The effects of uneven strength, extended service life, and balanced membrane flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solutions of the present invention will be further described below in combination with specific embodiments and accompanying drawings.

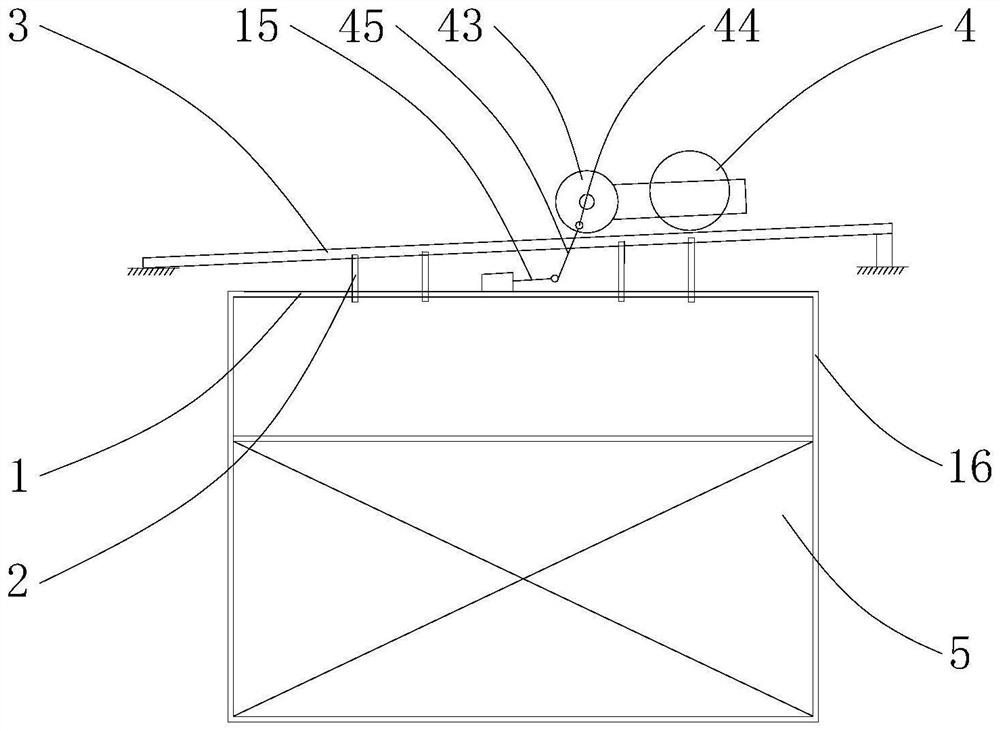

[0036] see Figure 1-6 As shown, the present embodiment provides a vibrating device for a membrane assembly, the membrane assembly 5 is a cuboid, and the vibrating device includes a suspension assembly 1 for suspending the membrane assembly 5, a roller assembly 2 connected to the suspension assembly 1, and a The support assembly 3 for suspending the roller assembly 2 , the support assembly 3 includes guide rails 32 for suspending the roller assembly 2 .

[0037] see figure 1 As shown, the support assembly 3 , the suspension assembly 1 and the membrane assembly 5 are arranged sequentially from top to bottom, and the suspension assembly 1 includes a suspension column 16 for suspending the membrane assembly 5 .

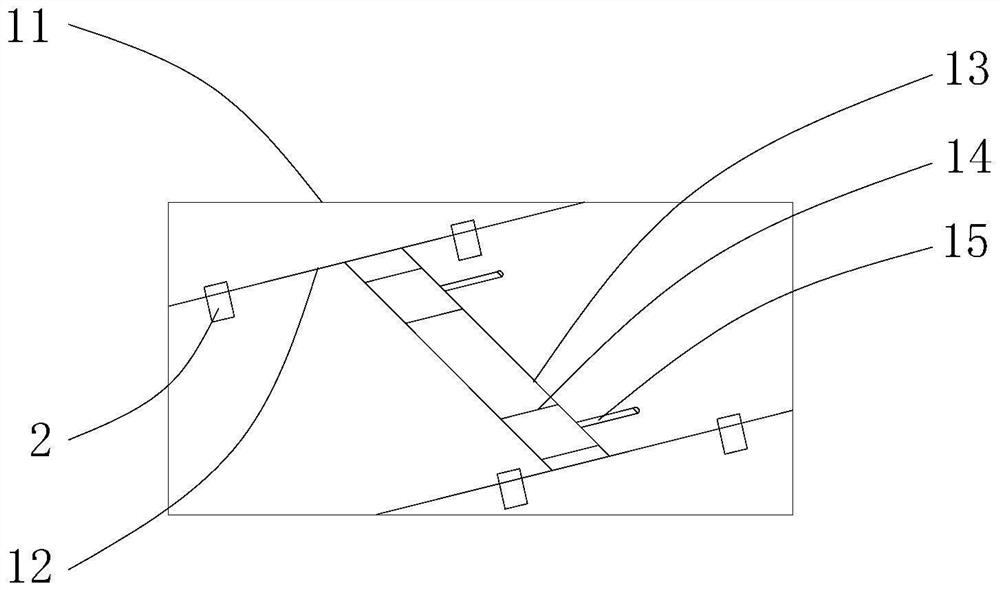

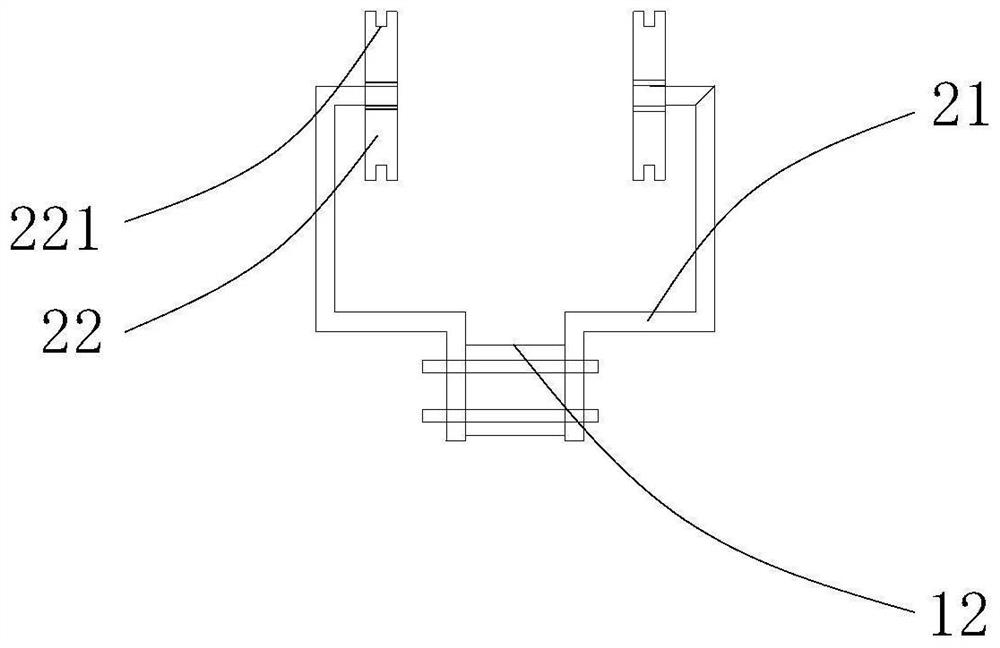

[0038] see figure 2 As shown, the above-mentioned suspension assembly 1 includes a suspension frame 11 parall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com