Colorful heat transfer printing device

A printing device and a colorful technology, which are applied to inking devices, printing, ink ribbon cassettes, etc., can solve the problems of inability to flexibly change the printing sequence, difficult control of printing color registration accuracy, and high cost of electronic parts, so as to facilitate the expansion of the ribbon library. , low cost and light structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

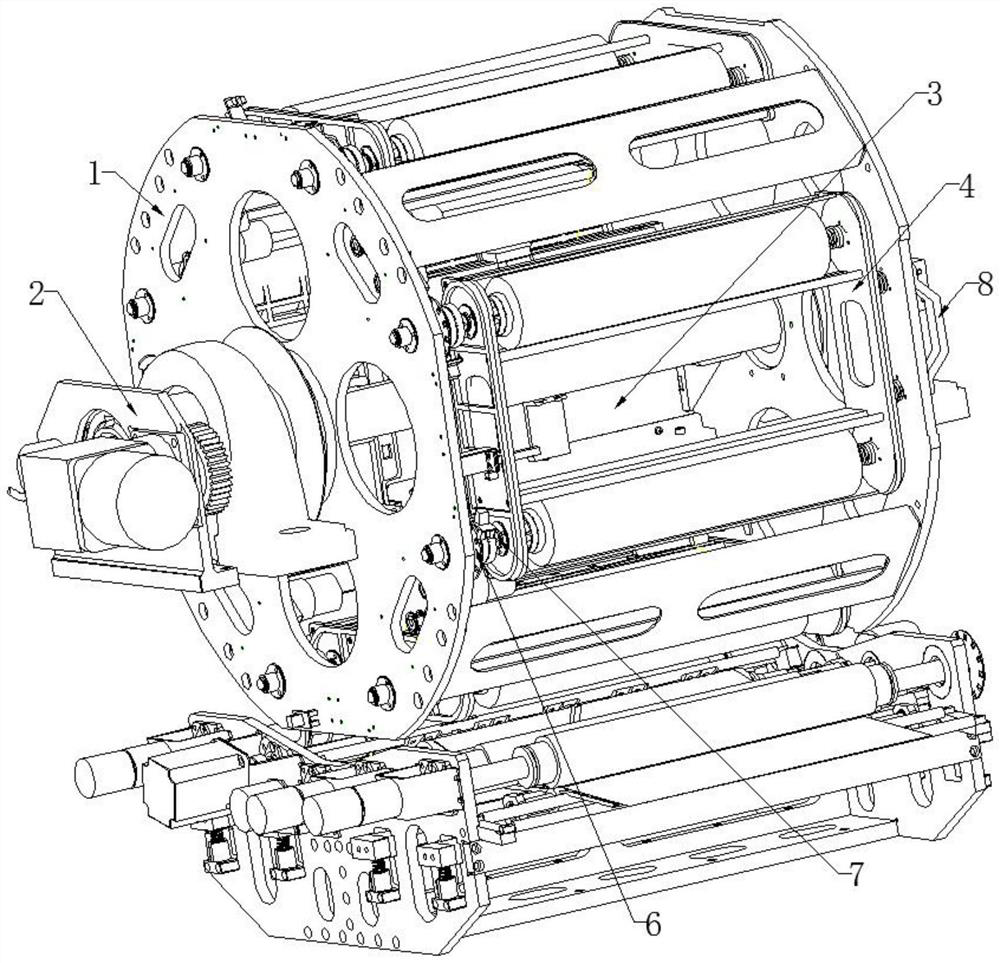

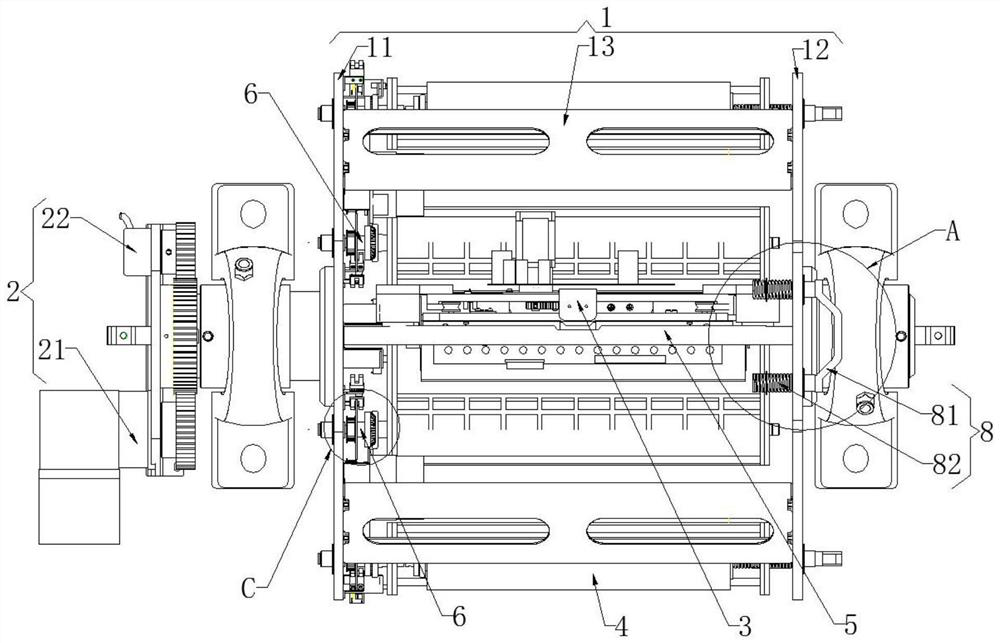

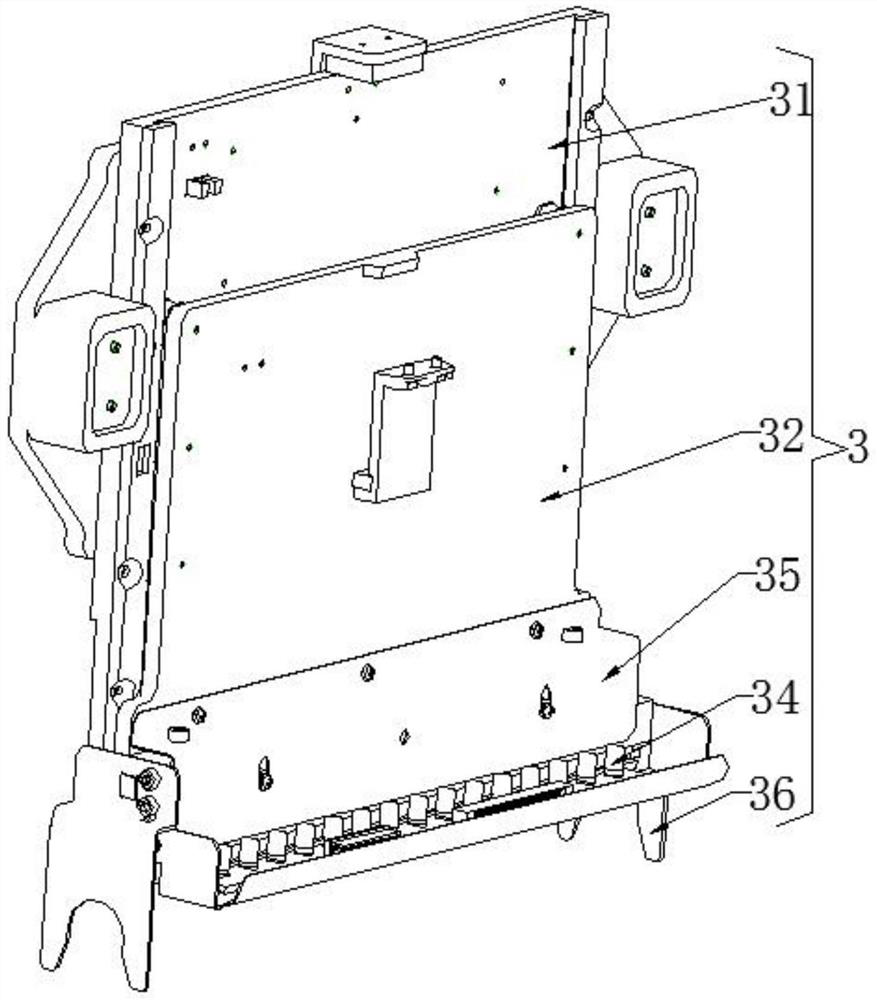

[0034] Such as Figure 1-8As shown, this embodiment provides a multi-color thermal transfer printing device, including a housing 1, a first driving device 2, a printing device 3, a beam 5, a frame and a carrier, and the left and right sides of the housing 1 are respectively fixed with tube shafts. , the two tube shafts are rotatably connected to the frame; the first driving device 2 is installed on the frame, and its drive end is connected to any one of the tube shafts; the printing device 3 is arranged in the housing 1, and the two ends Pass through and pass through two tube shafts, and are fixedly connected with the frame, and the printing end of the printing device 3 faces downward; a plurality of ribbon cassette...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com