Foreign fiber sorting device for fabric production

A foreign fiber and sorting device technology, applied in the field of fabric production, can solve the problems of waste of resources, difficult to remove, and affect spinning processing, etc., to achieve the effect of avoiding waste of resources and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

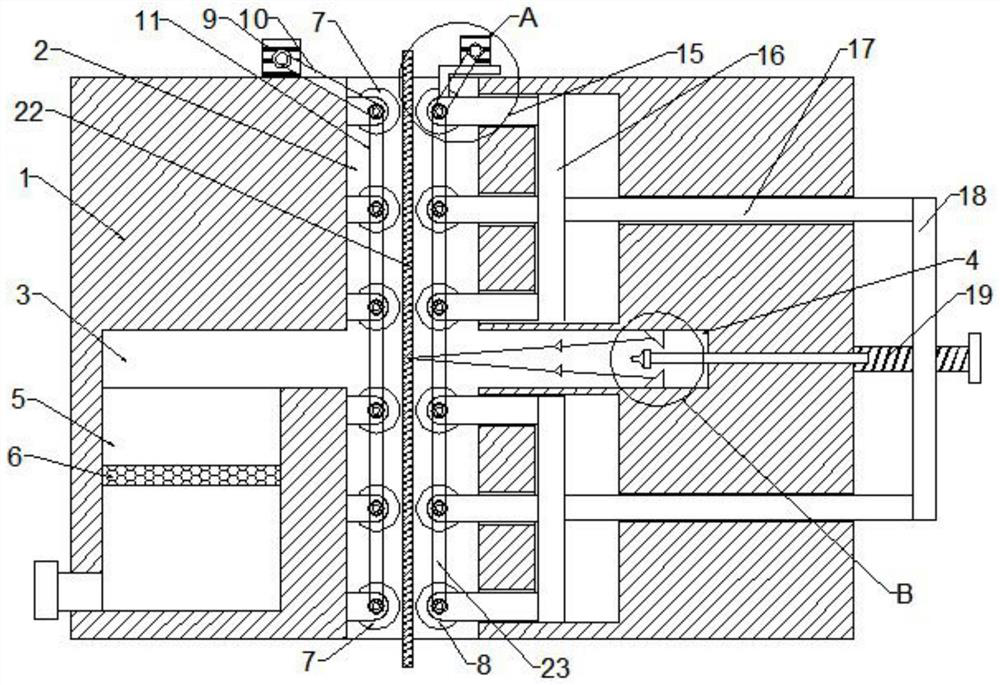

[0032] As an embodiment of the present invention, please refer to Figure 1 to Figure 3 : A kind of heterosexual fiber sorting device for fabric production, comprising a main body 1, the main body 1 is provided with a cotton cavity 2, a collection cavity 3 and a detection cavity 4, thin cotton 22 passes through the cotton cavity 2, and also includes :

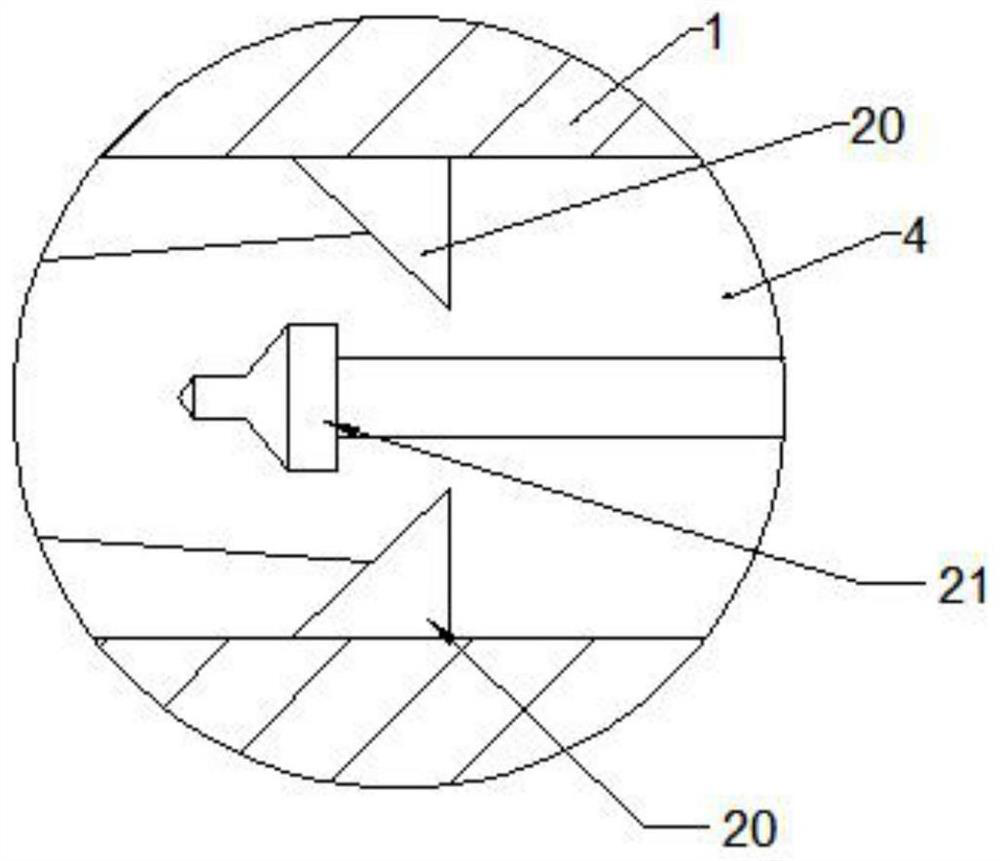

[0033] A detector 20, the detector 20 is arranged in the detection chamber 4;

[0034] A high-pressure water spray gun 21, the high-pressure water spray gun 21 is arranged in the detection chamber 4;

[0035] A pressing assembly, the pressing assembly is arranged in the cotton cavity 2, and is used for pressing and conveying the thin cotton 22;

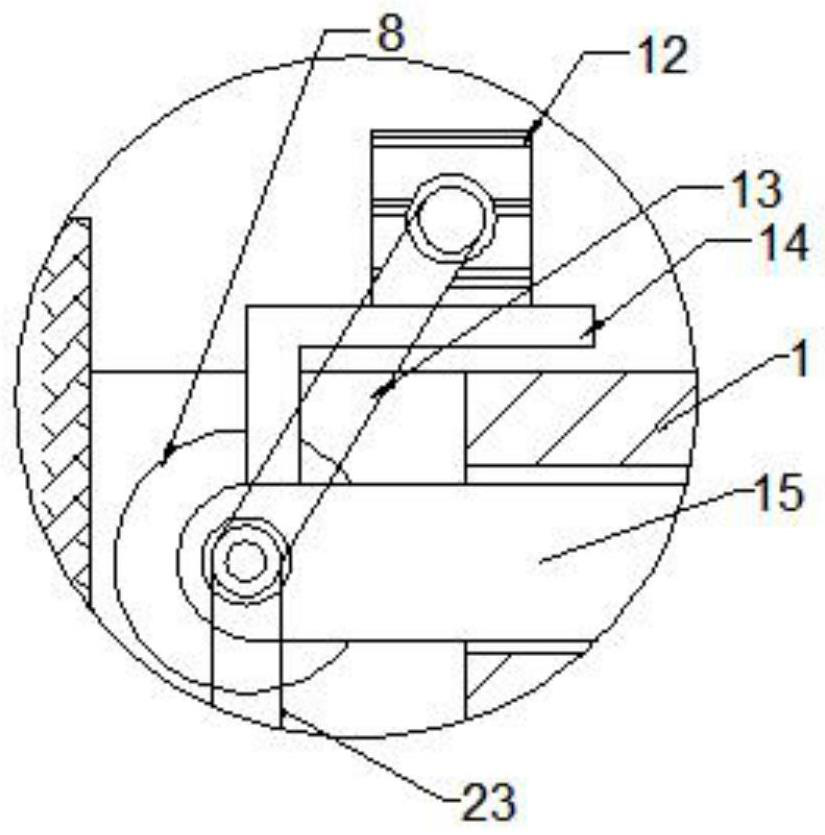

[0036] Wherein, the pressing assembly includes:

[0037] Conveying roller one 7, described conveying roller one 7 is arranged on one side in the described cotton cavity 2, and the quantity of described conveying roller one 7 is several;

[0038] Two conveying rollers 8, the two con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com