Backlight module and display device thereof

A backlight module and display panel technology, applied in optics, nonlinear optics, instruments, etc., can solve the problems that connectors and other electronic components cannot be placed, connectors cannot be placed, and occupy a large area, so as to improve optical efficiency And use performance, solve optical inhomogeneity, improve the effect of use performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

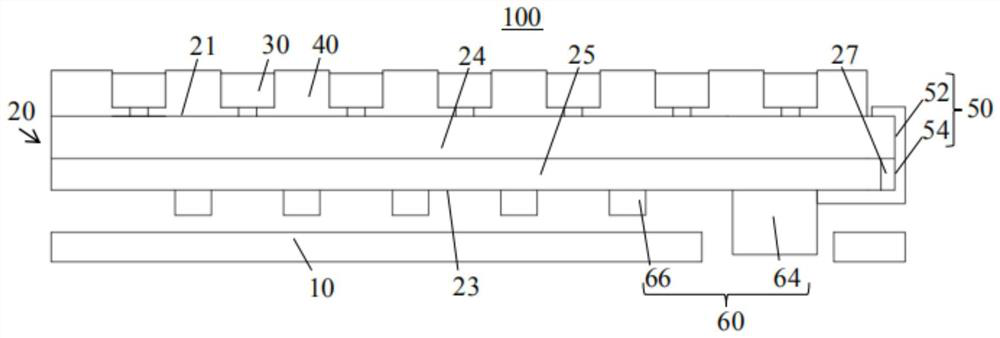

[0026] An embodiment of the present application provides a backlight module for a Mini light-emitting diode (Light-Emitting Diode, LED). see figure 1 As shown, in the backlight module 100 provided in this application, the backlight module 100 includes a backplane 10, a lamp panel 20, a plurality of light emitting elements 30, and a side wiring layer 50, wherein the lamp panel 20 includes The circuit surface 21 and the non-circuit surface 23 are opposite to each other. The backplane 10 is arranged adjacent to the non-circuit surface 23, that is, the non-circuit surface 23 faces the backplane 10, and the non-circuit surface 23 is provided with multiple An electronic device 60, a plurality of light-emitting elements 30 are arranged in an array on the circuit surface 21, and are electrically connected to the circuit surface 21, and the side wiring layer 50 extends from the circuit surface 21 to the non-circuit surface 23, and is electrically connected to multiple light-emitting e...

Embodiment 2

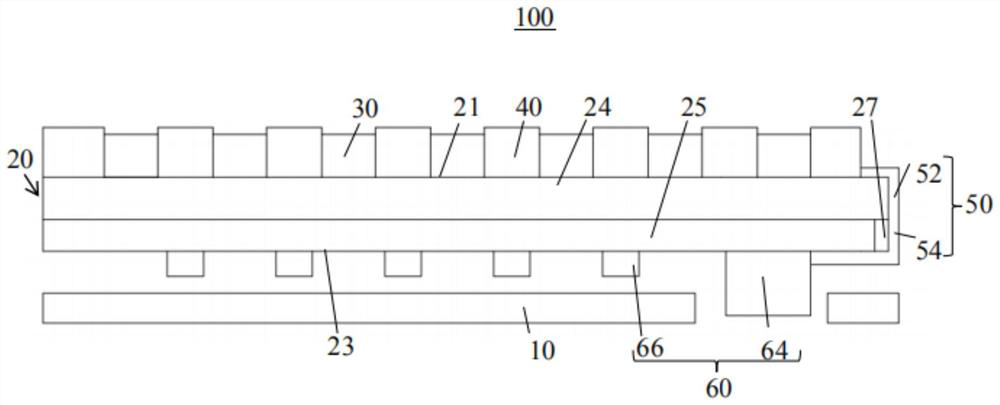

[0047] read on figure 2 , figure 2 It is a structural schematic diagram of the second embodiment of the backlight module disclosed in this application. The second embodiment of the present application and the above figure 1 The first embodiment shown is different in that: the anti-light absorption layer 40 is a reflective sheet, that is, the reflective sheet can reflect that the line surface 21 points to the light emitting element 30, and the light emitting element 30 points to the line The light from two directions on the surface 21, the anti-light absorption layer 40 is arranged on the circuit surface 21, and the anti-light absorption layer 40 is provided with a through installation hole (not marked) corresponding to the position of the light-emitting element 30. Each of the light emitting elements 30 is disposed in the mounting hole and electrically connected to the circuit surface 21 . In this embodiment, the depth of the installation hole is greater than the height o...

Embodiment 3

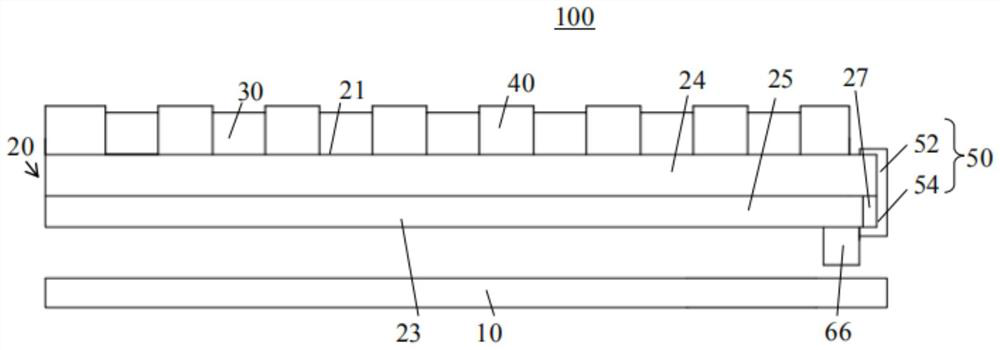

[0051] Please also refer to image 3 , image 3 It is a schematic structural diagram of the third embodiment of the backlight module disclosed in this application. The difference between the third embodiment of the present application and the first embodiment and the second embodiment above is that the electronic device 60 in the backlight module 100 only includes an electronic component 66 , ie does not include a connector 64 . The electronic component 66 is directly electrically connected to the second connection section 54, that is, the light-emitting element 30 and the electronic component 66 are directly electrically connected on the non-circuit surface 23 through the side wiring layer 50, and the electronic The element 66 provides electric energy for the normal operation of the backlight module 100 .

[0052] In one embodiment, the electronic component 66 may include but not limited to: a flexible circuit board, a carbon nanotube (Carbon Nanotube, CNT), a driver chip, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap