Method for manufacturing ceramic electronic component

A technology of electronic components and manufacturing methods, which is applied in the parts, electrical components, circuits and other directions of fixed capacitors, can solve the problems of hindering the compactness of the electrode layer from burning, and achieve the effect of strong bearing capacity and not easy to be damaged.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

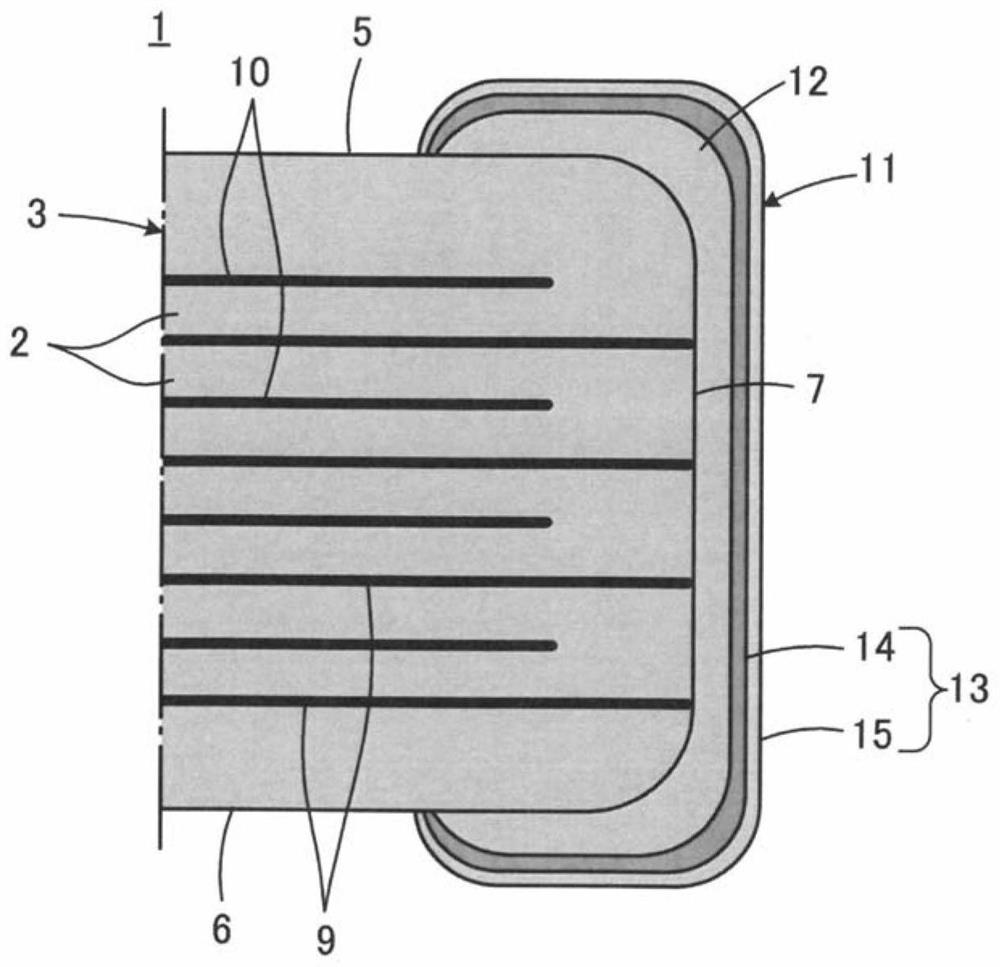

[0037] When describing a ceramic electronic component produced by applying the production method according to the present invention, a laminated ceramic capacitor is used as an example of a ceramic electronic component.

[0038] refer to figure 1 A multilayer ceramic capacitor 1 includes a ceramic body 3 including a plurality of stacked ceramic layers 2 , and the plurality of ceramic layers 2 include dielectric ceramics. The ceramic body 3 has a first main surface 5 and a second main surface 6 facing each other, a first end surface 7 connecting the first main surface 5 and the second main surface 6, and a first end surface 7 connected to the first main surface 5 and the second main surface 6, although not shown. The second end face facing the first end face 7, although not shown, also has a figure 1 1st side surface and 2nd side surface which extend parallel to paper surface and oppose mutually.

[0039] The ceramic body 3 further includes a plurality of first internal elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com