Integrated spraying process for bumper and grille of automobile

A technology for automobile bumpers and bumpers, which is used in coatings, spray devices, and devices for coating liquid on surfaces, etc., can solve the problem of limited space for robot spraying trajectory, large bumper and grille, and small grille gap. and other problems, to achieve the effect of convenient spraying, avoiding leakage spraying, and avoiding orange peel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings.

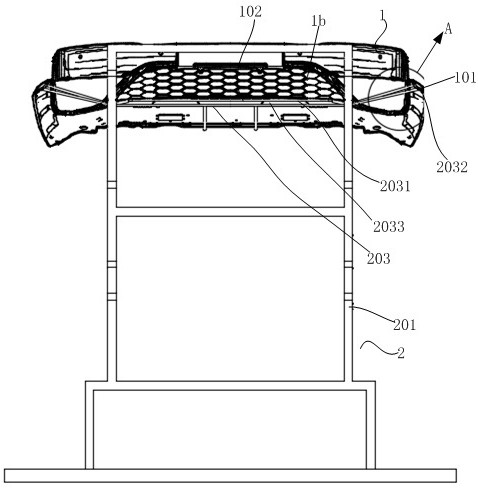

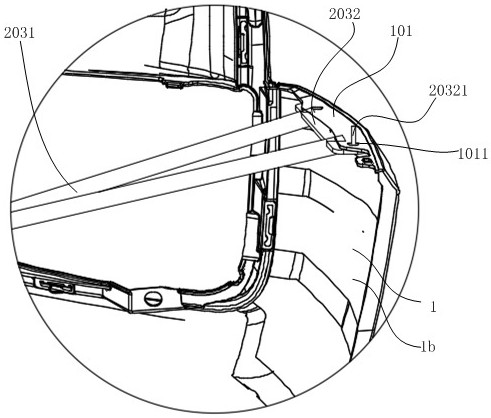

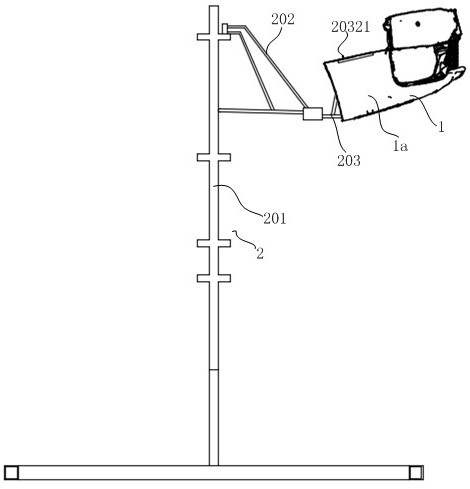

[0034] Please refer to Figure 1 to Figure 7 , the present invention provides an automobile bumper and grille integrated spraying process, which includes the following steps: Step 1) product positioning: hang the integrally formed bumper and grille 1 on the flip mounting bracket 2, and make the bumper and the outer surface 1a of the grille facing outward; Step 2) Spray primer: the robot sprays a layer of primer on the bumper and grille 1 from the outside, wherein the primer contains conductive carbon powder to improve adhesion and make Improve the painting rate of the color paint to avoid the orange peel phenomenon; step 3) spray the color paint; step 4) spray the varnish: after the color paint is leveled, first, the robot sprays the first layer on the bumper and grille 1 from the outside For varnish, after the first layer of var...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com