Workpiece holding tool in machining area of building material machining machine

A technology for processing machinery and processing areas, applied in the field of workpiece holding tooling, which can solve the problems of position deviation of building material workpieces, lack of clamping stability monitoring function, injury of surrounding staff, etc., and achieve the effect of avoiding rapid position deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

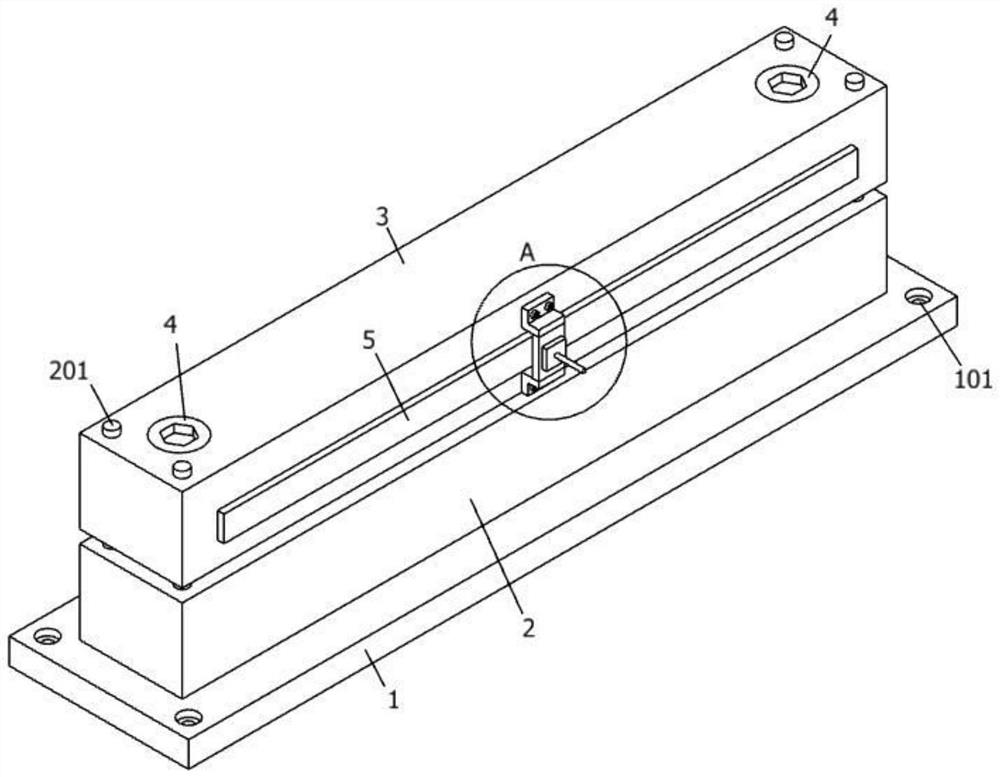

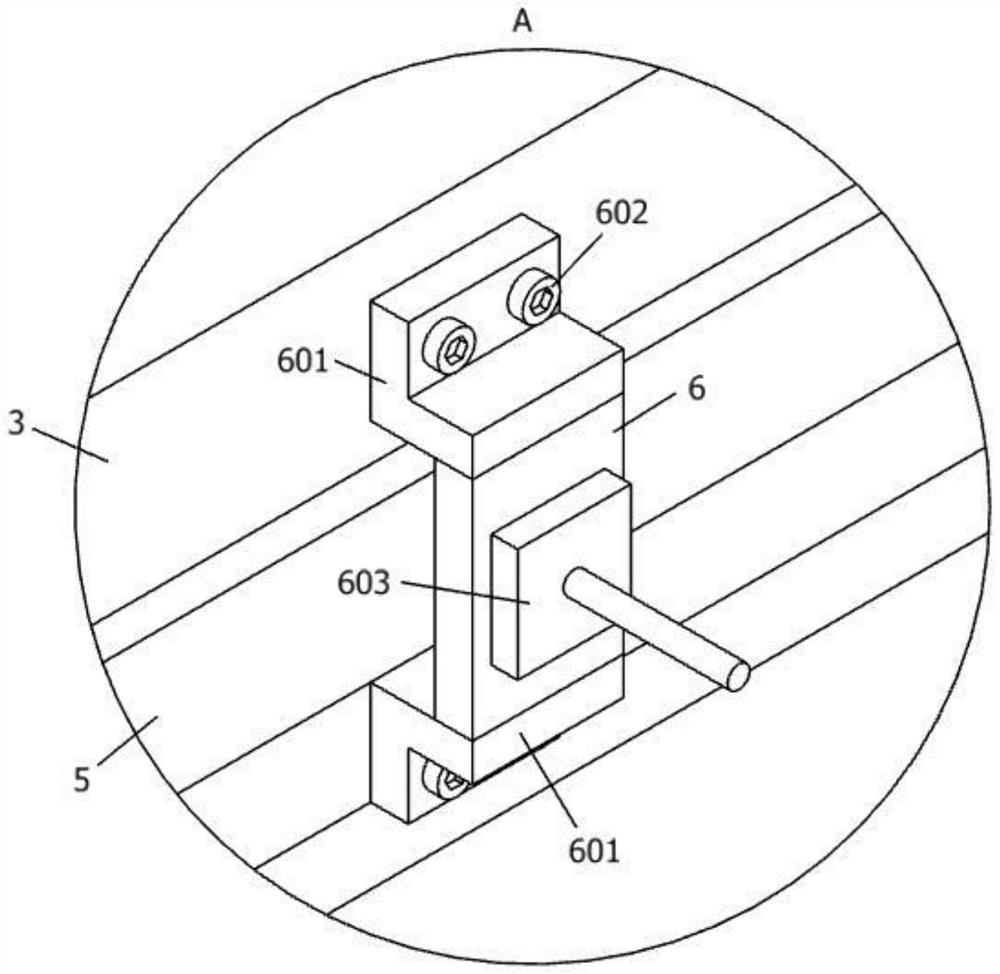

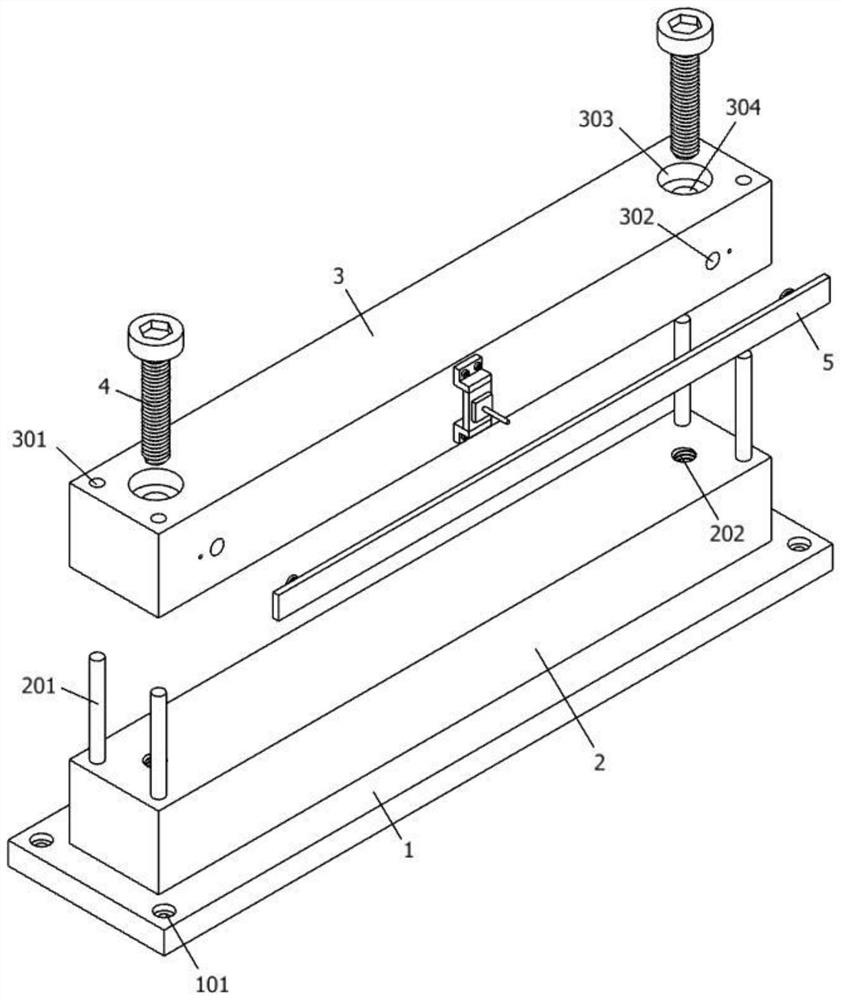

[0028] Example: Please refer to Figure 1 to Figure 8 :

[0029] The present invention proposes a workpiece holding tool in the processing area of a building material processing machine, comprising: a mounting base 1, which is in a rectangular block structure, and a mounting bracket is provided at four corners of the top surface of the mounting base 1 The hole position 101, the top surface of the installation base 1 is fixed with a holding tooling seat 2, and the holding tooling seat 2 has a rectangular block structure; the four edge corners of the top surface of the holding tooling seat 2 are all provided with a limit post 201, the limit The column 201 is a cylindrical structure, and a holding tooling block 3 is arranged on the top of the holding tooling seat 2, and the holding tooling pressing block 3 has a rectangular block structure, and a limit hole is provided at the four corners of the top surface of the holding tooling pressing block 3 301, the limit hole 301 is a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com