Locomotive wheelset intelligent efficient pushing device suitable for field without traction line

A technology without pulling wires and pushing devices, which is applied in the direction of mechanical conveyors, conveyors, transportation and packaging, etc., can solve the problems of difficult maintenance, repair, replacement, high labor intensity of employees, and many faults of pulling wires, etc., to reduce the space The effect of maintaining cost, improving efficiency and intelligence, and reducing site layout cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] specific implementation plan

[0017] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

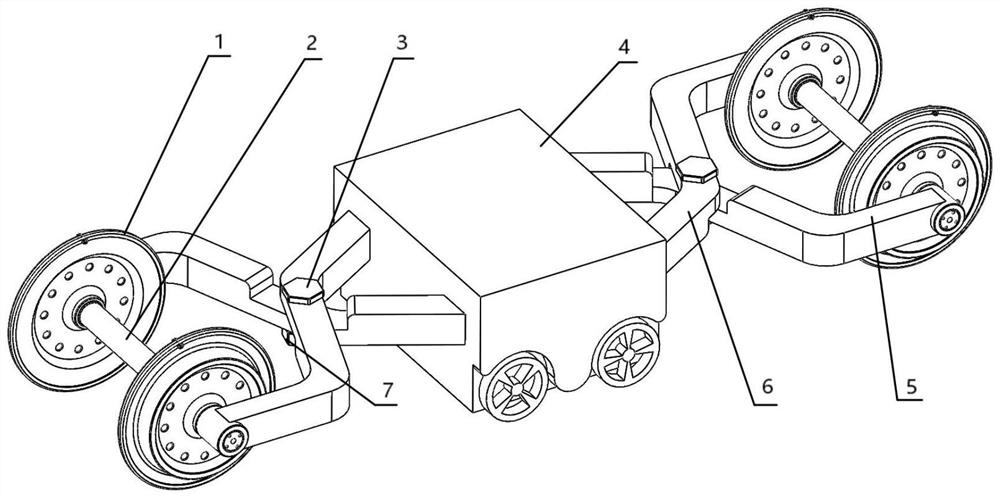

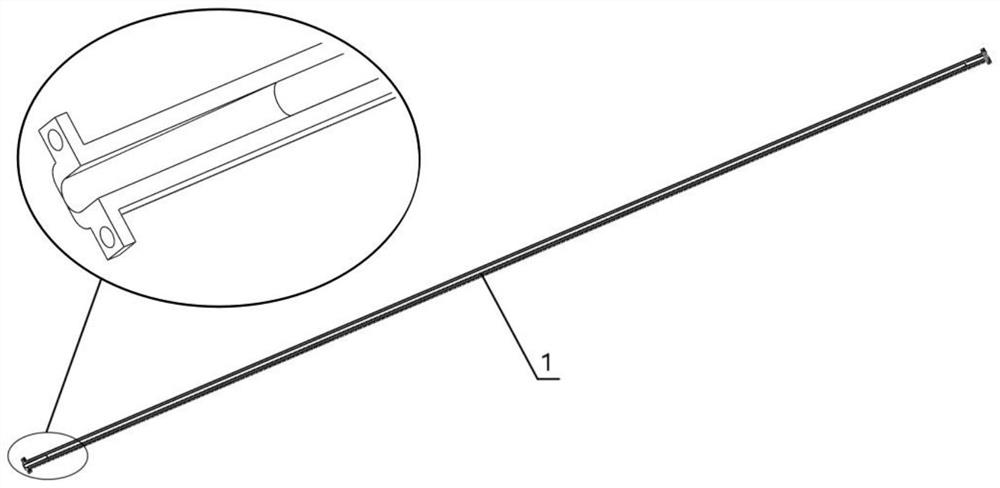

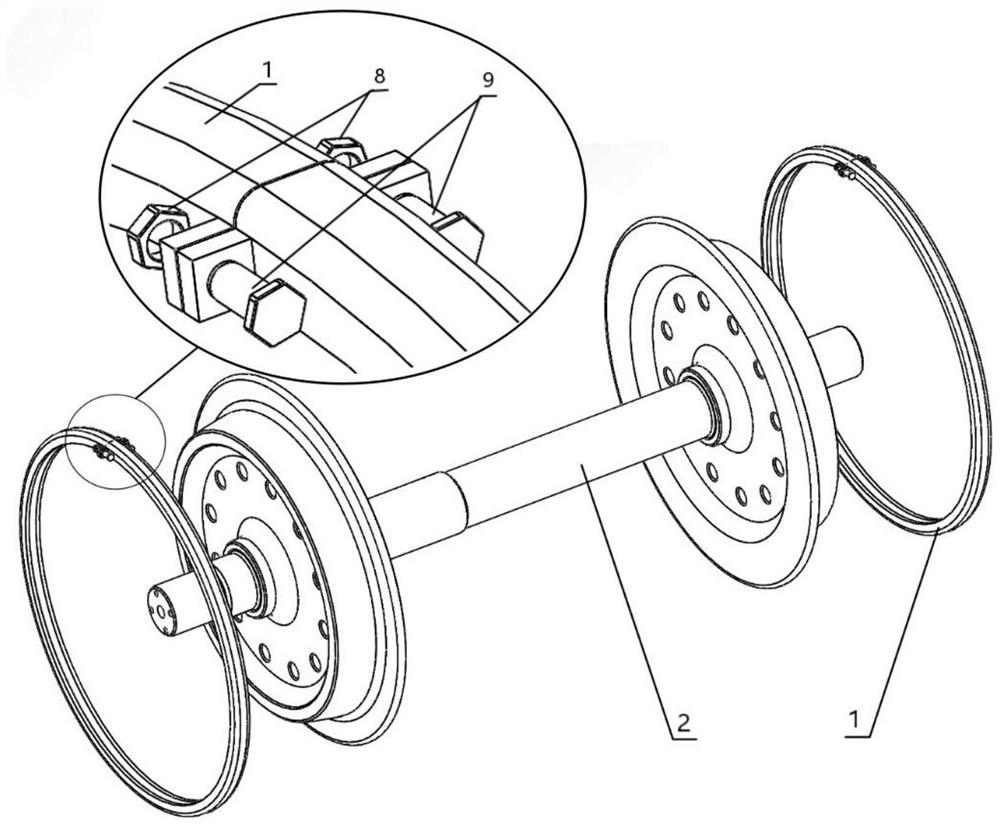

[0018] Such as figure 1 As shown, the present invention is an intelligent and efficient pushing device for a locomotive wheel set suitable for a field without a traction line, comprising a rubber sleeve (1), a rubber sleeve clamping bolt (9), a clamping nut (8), an upper push rod ( 6), the lower push rod (5), the push rod connecting bolt (3), the connecting nut (7), the AGV trolley (4), and the push rod driving device. The rubber sleeve (1) can be stretched or bent, and the rubber sleeve (1) and the wheel set (2) are assembled together by clamping the bolt (9) and the nut (8) before pushing; the push rod driving device is installed on the AGV trolley (4) Inside, the end of the connection between the push rod and the AGV trolley (4) is reciprocated and translated, and the upper push rod (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com