Precise weighing and automatic sorting production process

An automatic sorting and production process technology, applied in sorting, detailed information of weighing equipment, weighing and other directions, can solve the problems of high weight classification requirements, inaccurate weighing, etc., to reduce the difficulty of disassembly and improve the accuracy Sex, the effect of increasing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

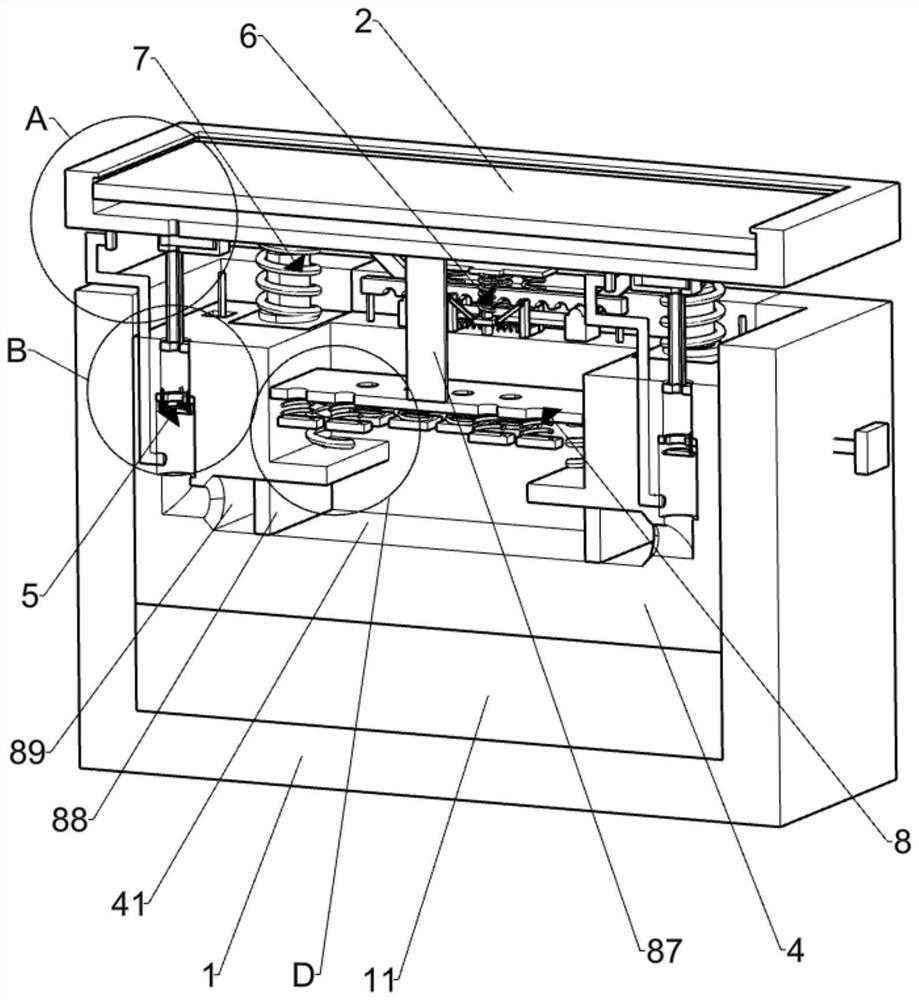

[0031] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

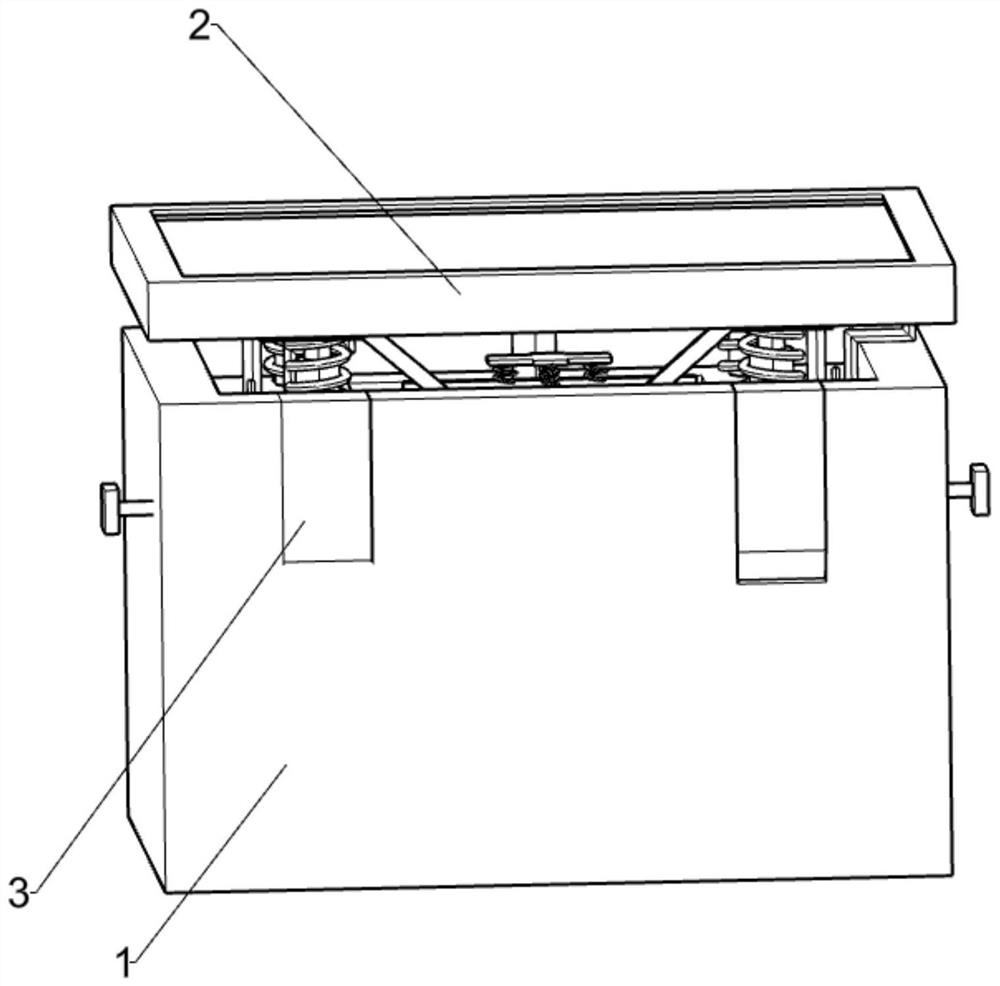

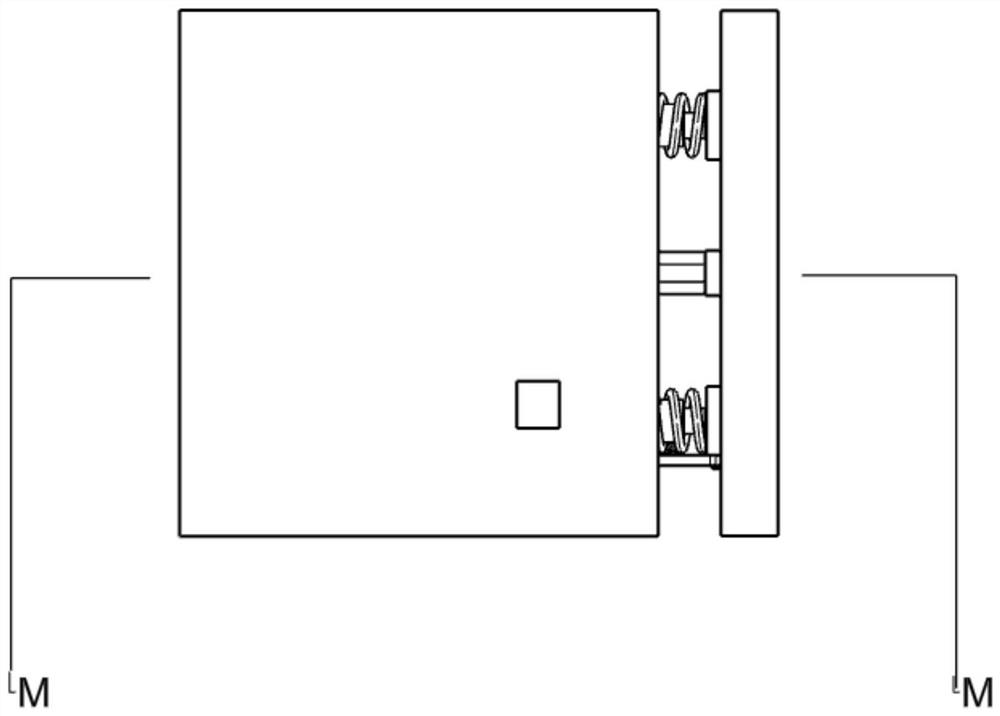

[0032] Such as Figure 1-13 As shown, a precision weighing automatic sorting production process includes the following steps:

[0033]The battery is weighed and sorted through the precision weighing automatic sorting production line; the weighing automatic sorting production line includes a cleaning station, a conveying station, a weighing station, and a binning station; the steps include: A. Put it into the cleaning station to clean it; B. After the product is cleaned, it is sent into the product flow channel with a vibrating plate; C. The product falls from the product flow channel to the precision shock-absorbing weighing device, and then weighed; The precision shock-abso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com