Semi-automatic wire rod shell inserting machine

A shell inserter and semi-automatic technology, which is applied in the assembly/disassembly of contacts, etc., can solve the problems affecting the normal use of the wire, the shell is not plugged in place, the positioning of the wire is inaccurate, etc. Operation, high precision shell insertion, good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

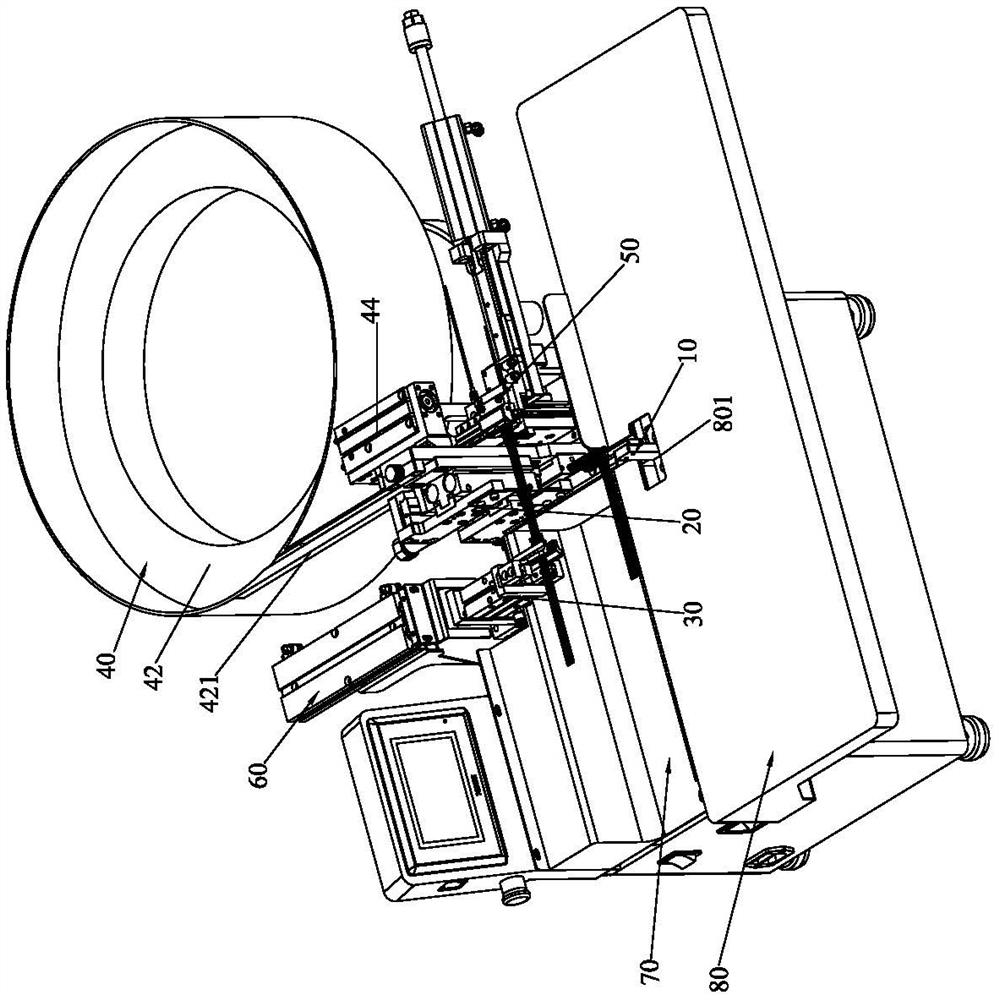

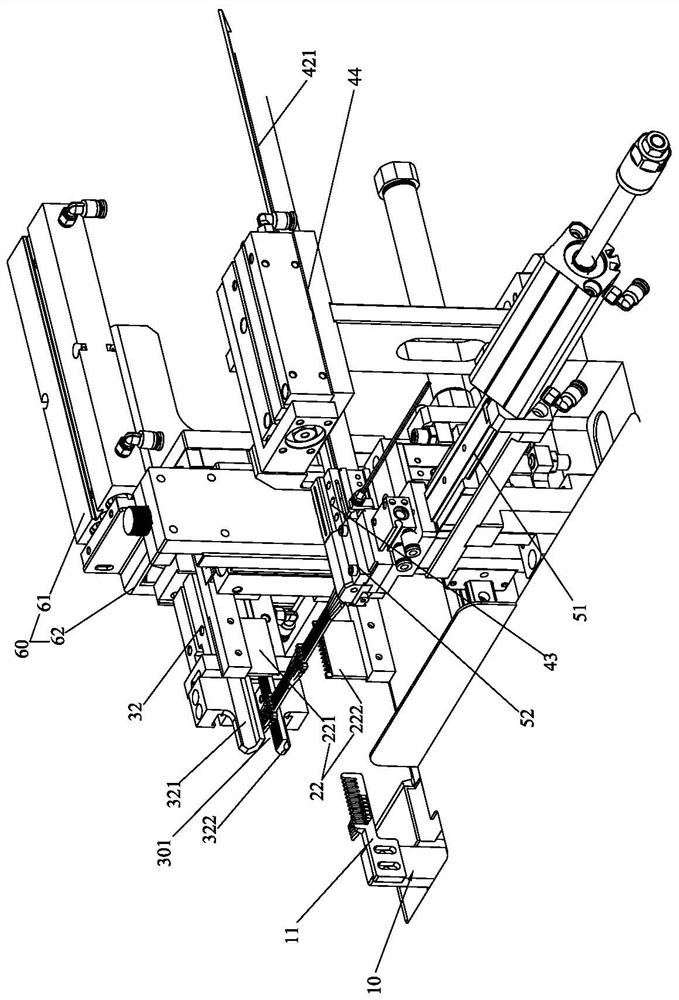

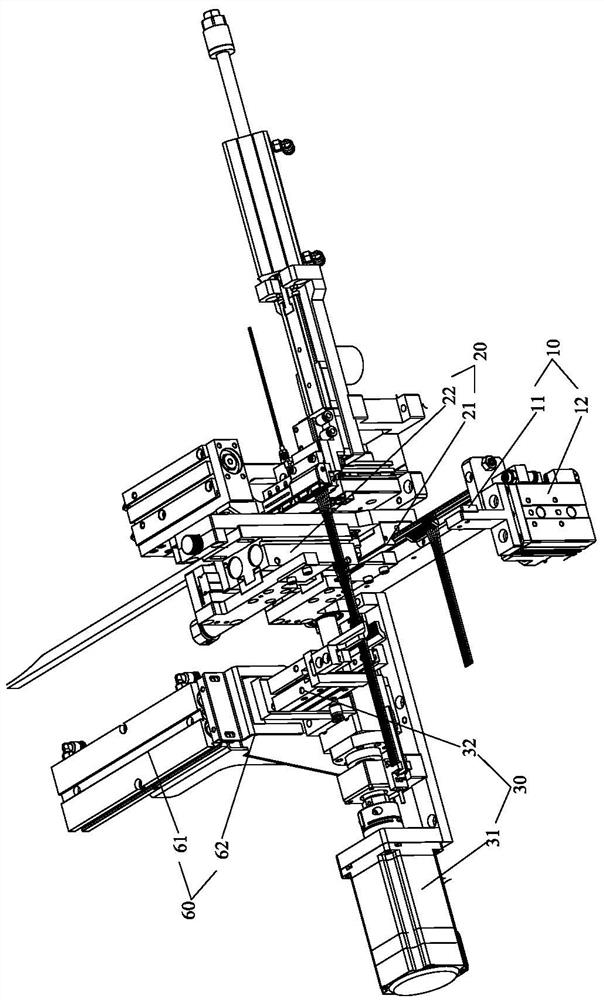

[0050] Please refer to Figure 1 to Figure 5 As shown, it shows the specific structure of a preferred embodiment of the present invention, including a wire management tool 10, a terminal clamping and feeding mechanism 20, a wire clamping mechanism 30, a housing feeding mechanism 40, a socket Mechanism 50, a material-cutting mechanism 60 for pushing wire material-cutting.

[0051] The wire management fixture 10 includes a wire management board 11, and the wire management board 11 is provided with a plurality of wire management grooves 101 for inserting wire rods. After the wire rods are inserted into the wire management grooves 101, the terminal part of the wire rods Exposed outside the wire management groove 101, usually when the wire is inserted, it is inserted from the first wire management groove 101 at the end; the wire wire management jig 10 also includes a first lifting device 12, and the wire management The board 11 is arranged on the first lifting device 12, and the f...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap