Temperature self-adaptive welding device for track material

An adaptive and orbital technology, applied in the direction of auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of organic combination of heat dissipation at the welding place, no protective structure, etc., and achieve the effect of rapid adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

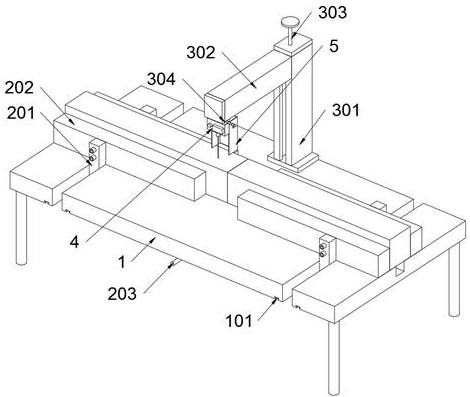

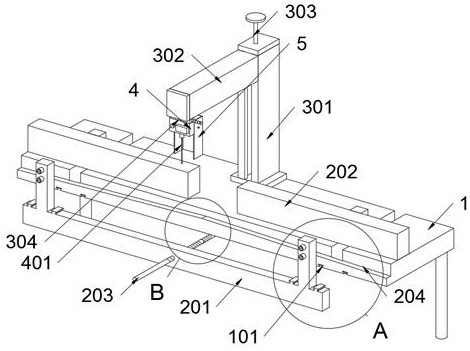

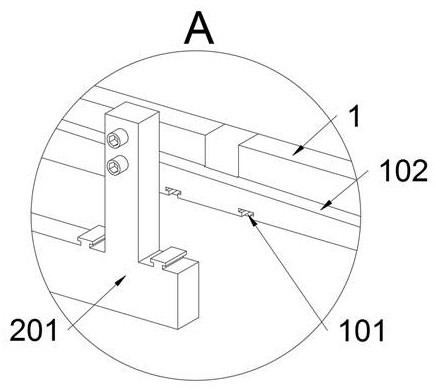

[0039] as attached figure 1 To attach Figure 8 Shown:

[0040] The invention provides a temperature self-adaptive welding device for rail materials, which includes a table body 1; the table body 1 is placed on the ground, and a clamping part 2 is installed on the table body 1, and an adjustment Part 3; the welding machine 4 is installed on the adjustment part 3, and the auxiliary part 5 is installed on the welding machine 4; The upper rotation is connected with the rotating shaft 502, and the impeller 505 is installed on the rotating shaft 502, so that when the impeller 505 rotates, the wind force heat dissipation of the welding machine 4 and the wind force cooling of the welding place can be realized; the gear row 504, the gear row 504 is welded on the mounting arm 302 The gear 503, the gear 503 is installed on the rotating shaft 502, and the gear 503 is meshed with the gear row 504, and the rotating shaft 502 and the impeller 505 are in a rotating state when the sliding b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com