Fabricated building stair module

A prefabricated, stair technology, applied in the direction of stairs, buildings, building structures, etc., can solve problems such as troublesome cleaning, a large amount of water stains, affecting people's normal walking, etc., and achieve the effect of improving water stains or dust adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

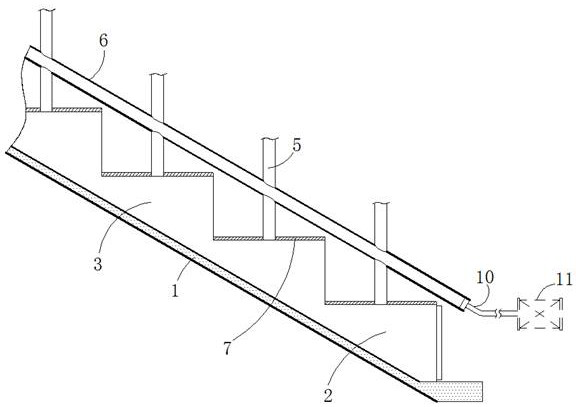

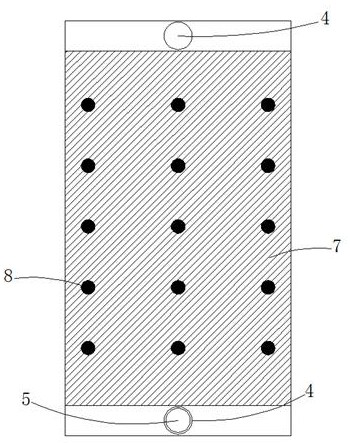

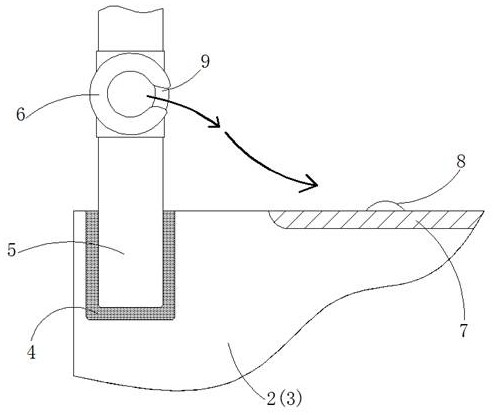

[0029] An assembled building staircase module including a base 1 and a first ladder station 2 and a second ladder platform 3, the second ladder platform is located above the first ladder station 2, and the first ladder station 2 is mounted at the bottom of the base 1. End, the upper surface side of the first ladder stage 2 and the second ladder 3 are provided with the positioning hole 4, and the positioning hole 4 is coincided with the bottom end of the railing 5, and includes the decorative plate 7, the decorative plate 7 is installed in the first The upper end surface of the ladder 2 and the second ladder 3, and the upper end surface of the decorative plate 7 is also provided with protrusions 8 for non-slip, which may be elastic or non-elastic structures, and the surface has a friction, By setting the top end above the tip of the decorative plate 7, the sole is avoided with the surface of the decorative plate 7 when walking is absent from the surface of the decorative plate 7, a...

Embodiment 2

[0032] Unlike the embodiment, the removing device is composed of a second air hole 12, a cavity 13, and a straw 15, and the second air hole 12 communicating with the bottom end of the cavity 13 is opened on the surface of the projection 8, and the cavity 13 vertically through the interior of the vertical rod 14, the projection 8 is fixed to the upper end surface of the vertical rod 14, and the top end of the vertical rod 14 is mounted on the upper end surface of the decorative plate 7 through the connecting member 16, and the mid-stage activity of the vertical rod 14 is connected In the pallet 17, the pallet 17 is fixed to the lower end surface of the decorative plate 7, and the bottom end of the cavity 13 is connected to the suction device through the straw 15, and the suction device is connected to the straw 15, and mounted in the second ladder The vertical pipe 19, the cavity 13, and the second air hole 12 in the stage 3, the decorative plate 7 surface water is sued out, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com